In short, PTFE guide strips are most commonly used in hydraulic and pneumatic cylinders, shock absorbers, presses, and various machinery within the agriculture, robotics, and food processing industries. They serve as bearing elements that guide pistons and rods, preventing metal-to-metal contact and absorbing transverse forces.

The fundamental purpose of a PTFE guide strip is to provide a low-friction, wear-resistant guide for moving components. This protects critical seals and metal parts from damage, significantly extending the service life and reliability of the equipment.

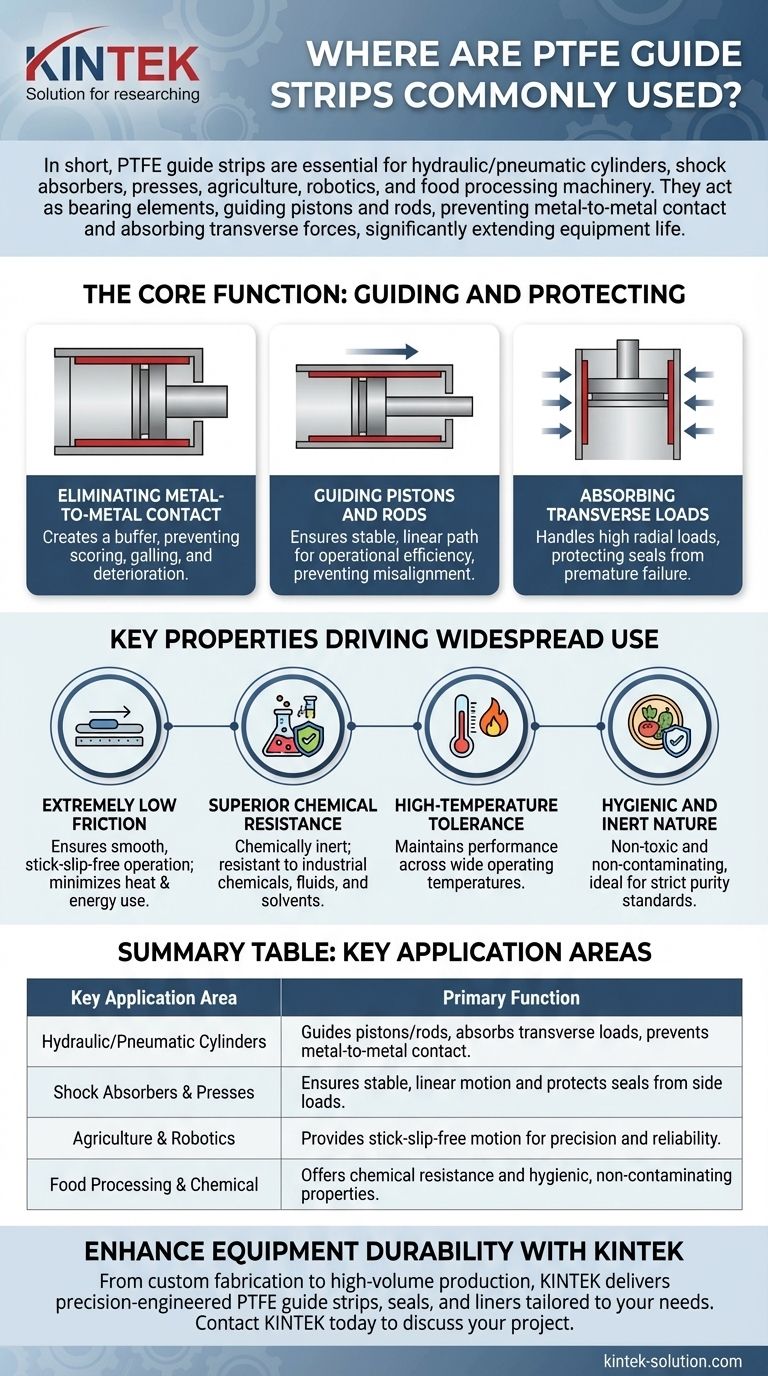

The Core Function: Guiding and Protecting

PTFE guide strips solve a critical mechanical problem: managing movement and force in dynamic systems. They are not seals themselves, but they are essential for the proper function of the entire sealing system.

Eliminating Metal-to-Metal Contact

The primary role of a guide strip is to create a buffer between moving metal components, such as a piston and a cylinder bore.

This physical separation is crucial for preventing scoring, galling, and the general deterioration of expensive-to-replace metal parts.

Guiding Pistons and Rods

In systems like hydraulic cylinders, the guide strip ensures the piston and rod move in a stable, linear path.

This precise guidance is vital for operational efficiency and prevents misalignment that could damage seals and other internal components.

Absorbing Transverse Loads

Guide strips are engineered to handle high radial loads (side loads) that occur during operation.

By absorbing these forces, they protect the primary seals from being subjected to pressures and movements they were not designed to withstand, thereby preventing premature seal failure.

Key Properties Driving Widespread Use

The selection of PTFE (Polytetrafluoroethylene) for guide strips is not accidental. The material possesses a unique combination of properties perfectly suited for these demanding applications.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, which ensures smooth, stick-slip-free operation.

This characteristic reduces the energy required to move the components and minimizes heat generation, leading to better system efficiency and longevity.

Superior Chemical Resistance

PTFE is chemically inert and resistant to nearly all industrial chemicals, fluids, and solvents.

This makes PTFE guide strips the ideal choice for systems used in chemical processing, food and beverage, and other corrosive environments.

High-Temperature Tolerance

These guide strips maintain their structural integrity and performance characteristics across a wide range of operating temperatures.

This thermal stability allows them to be used reliably in high-temperature applications like injection molding presses without degrading.

Hygienic and Inert Nature

Because PTFE is non-toxic and does not contaminate its environment, it is highly valued in applications with strict purity standards.

This is a primary reason for its use in food processing equipment, pharmaceutical manufacturing, and even medical devices.

Making the Right Choice for Your Goal

Selecting a PTFE guide strip is about matching its inherent benefits to the specific demands of your equipment.

- If your primary focus is extending equipment life: PTFE guide strips are a critical component for preventing wear on expensive metal parts and protecting seals from damaging side loads.

- If your primary focus is operational precision: The low-friction nature of PTFE ensures smooth, stick-slip-free motion, which is essential for robotics and high-performance hydraulic systems.

- If your primary focus is system reliability in harsh environments: The unmatched chemical and thermal resistance of PTFE ensures consistent performance where other materials would fail.

Ultimately, incorporating PTFE guide strips is a strategic decision to enhance the durability and performance of dynamic mechanical systems.

Summary Table:

| Key Application Area | Primary Function of PTFE Guide Strip |

|---|---|

| Hydraulic/Pneumatic Cylinders | Guides pistons/rods, absorbs transverse loads, prevents metal-to-metal contact. |

| Shock Absorbers & Presses | Ensures stable, linear motion and protects seals from side loads. |

| Agriculture & Robotics | Provides stick-slip-free motion for precision and reliability. |

| Food Processing & Chemical | Offers chemical resistance and hygienic, non-contaminating properties. |

Enhance the durability and performance of your equipment with precision-engineered PTFE components from KINTEK.

Whether you're designing hydraulic systems for heavy machinery, robotics requiring precise movement, or food processing equipment that demands hygienic materials, KINTEK delivers. We manufacture high-quality PTFE guide strips, seals, liners, and labware tailored to the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication ensures you get the perfect solution, from initial prototypes to high-volume production runs.

Contact KINTEK today to discuss your project requirements and discover how our PTFE components can solve your critical guiding and sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications