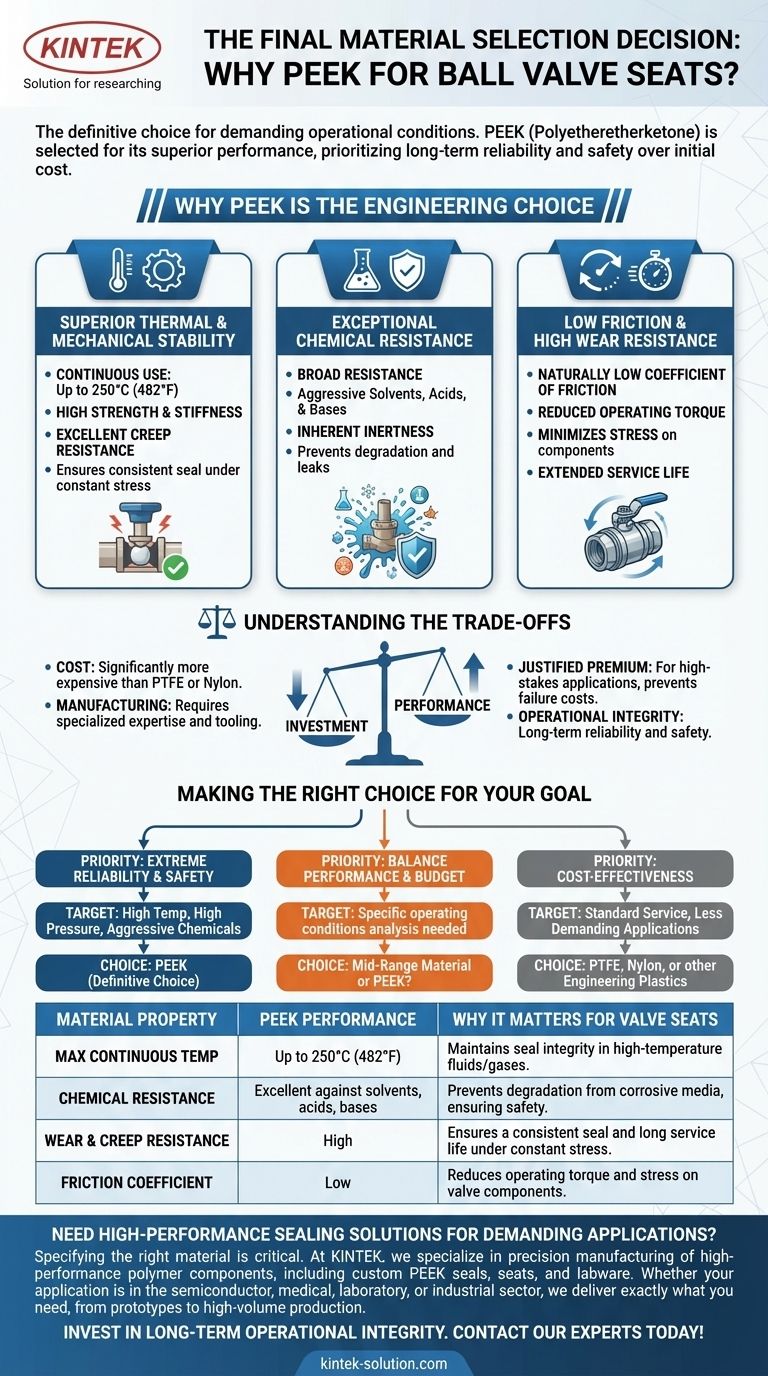

The final material selection decision was to use PEEK (Polyetheretherketone) for the ball valve seats in this application. This choice was driven by PEEK's superior performance characteristics under demanding operational conditions, prioritizing long-term reliability and safety over initial material cost.

The selection of PEEK is a strategic engineering decision. It signals that the application's performance requirements—specifically high temperature, high pressure, and chemical resistance—are critical enough to justify a premium material investment.

Why PEEK is the Engineering Choice

PEEK is a high-performance thermoplastic renowned for its exceptional mechanical properties and thermal stability. Its selection is rarely accidental; it is a deliberate choice for applications where other polymers would fail.

Superior Thermal and Mechanical Stability

PEEK maintains its strength and stiffness at continuous-use temperatures up to 250°C (482°F). This makes it suitable for high-temperature fluid and gas applications where materials like PTFE (Teflon) would deform.

This stability extends to its mechanical properties. PEEK exhibits excellent resistance to creep—the tendency of a material to deform permanently under constant stress—ensuring a consistent seal over the valve's lifetime.

Exceptional Chemical Resistance

The material is highly resistant to a broad range of chemicals, including aggressive industrial solvents, acids, and bases. This inherent inertness prevents material degradation that could lead to seal failure and leaks.

For applications involving corrosive media, PEEK provides a reliable barrier, protecting the integrity of the valve and the safety of the system.

Low Friction and High Wear Resistance

PEEK has a naturally low coefficient of friction. This reduces the torque required to operate the valve, minimizing stress on the actuator and other components.

Its excellent wear resistance ensures that the valve seat can withstand the repeated rotational movement of the ball without significant material loss, extending the service life of the component.

Understanding the Trade-offs

Choosing a premium material like PEEK involves a clear understanding of its costs and limitations. The decision is always a balance between performance requirements and economic realities.

The Primary Factor: Cost

PEEK is significantly more expensive than common valve seat materials like PTFE or Nylon. The raw material cost and specialized processing requirements contribute to a higher price point for the finished component.

This cost must be weighed against the potential costs of failure, including downtime, maintenance, and safety incidents. In critical systems, the higher initial investment is often justified by the lower total cost of ownership.

Manufacturing and Processing Complexity

Machining PEEK requires specific expertise and tooling. While it has good machinability for a high-performance polymer, it is more demanding to work with than softer materials.

Improper machining can induce internal stresses, potentially compromising the component's performance. This necessitates careful selection of manufacturing partners with proven experience in handling this material.

Making the Right Choice for Your Goal

The selection of PEEK is a direct reflection of the application's priorities. Your own material choices should be guided by a clear understanding of your primary operational objectives.

- If your primary focus is extreme reliability and safety: PEEK is the definitive choice for applications with high temperatures, high pressures, or aggressive chemical media where failure is not an option.

- If your primary focus is cost-effectiveness for standard service: Materials like PTFE or other engineering plastics may offer sufficient performance for less demanding, general-purpose applications at a lower cost.

- If your primary focus is balancing performance and budget: A detailed analysis of the specific operating conditions is required to determine if a mid-range material could meet requirements or if the investment in PEEK is essential.

Ultimately, specifying a material like PEEK is an investment in long-term operational integrity.

Summary Table:

| Material Property | PEEK Performance | Why It Matters for Valve Seats |

|---|---|---|

| Max Continuous Temp | Up to 250°C (482°F) | Maintains seal integrity in high-temperature fluids/gases. |

| Chemical Resistance | Excellent against solvents, acids, bases | Prevents degradation from corrosive media, ensuring safety. |

| Wear & Creep Resistance | High | Ensures a consistent seal and long service life under constant stress. |

| Friction Coefficient | Low | Reduces operating torque and stress on valve components. |

Need High-Performance Sealing Solutions for Demanding Applications?

Specifying the right material is critical for the reliability and safety of your components. At KINTEK, we specialize in the precision manufacturing of high-performance polymer components, including custom PEEK seals, seats, and labware.

Whether your application is in the semiconductor, medical, laboratory, or industrial sector, we can help you navigate material selection and deliver components that meet your exact requirements—from prototypes to high-volume production.

Invest in long-term operational integrity. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What are the main technical features that influence the performance of PTFE diaphragms? Optimize for Durability & Chemical Resistance

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments