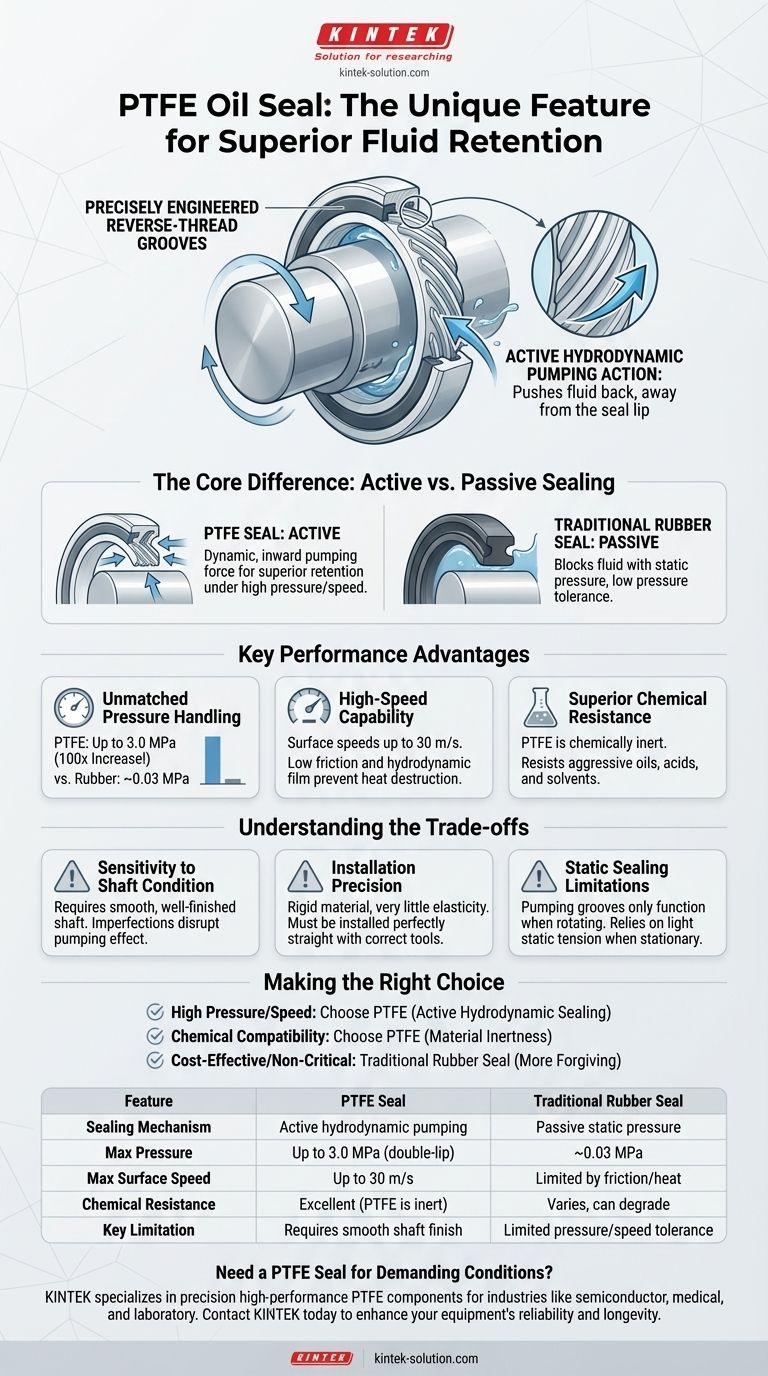

The single most unique feature of a PTFE oil seal for fluid retention is its use of precisely engineered reverse-thread grooves on the inner sealing wall. Unlike a passive rubber seal, these grooves use the shaft's rotation to create a hydrodynamic pumping action, actively pushing fluid back towards its source and away from the seal lip.

The core difference is a shift from passive to active sealing. While traditional rubber seals simply block fluid with static pressure, a PTFE seal's grooves create a dynamic, inward pumping force that provides superior fluid retention under high-pressure and high-speed conditions.

The Principle of Hydrodynamic Sealing

To understand the PTFE seal's advantage, you must first understand the concept of hydrodynamic sealing. It's a fundamentally different approach compared to traditional elastomeric (rubber) seals.

How Reverse-Thread Grooves Work

The grooves on the inner lip of a PTFE seal are angled against the direction of shaft rotation.

As the shaft spins, these tiny helical grooves act like a screw pump. They catch any fluid that reaches the seal lip and generate an inward thrust, actively transporting it back into the system.

This mechanism ensures a near-perfect seal even when faced with significant pressure that would easily overwhelm a standard seal.

The Contrast with Traditional Seals

A conventional rubber oil seal works on a much simpler principle: static radial force.

The rubber lip is slightly smaller than the shaft, creating a tight squeeze. This interference fit is what blocks the fluid, but it has a very low tolerance for pressure before it fails.

Key Performance Advantages Explained

The active, hydrodynamic design of PTFE seals translates directly into superior performance in demanding applications.

Unmatched Pressure Handling

This is the most dramatic advantage. A standard rubber seal can typically handle about 0.03MPa of pressure.

In contrast, a single-lip PTFE seal can manage 1.0MPa, and a double-lip design can withstand up to 3.0MPa. This is a performance increase of over 30 to 100 times.

High-Speed Capability

The low-friction nature of PTFE combined with the stable hydrodynamic film created by the grooves allows these seals to perform reliably at very high rotational speeds.

They are often rated for surface speeds up to 30m/s, an environment where the friction and heat generated would quickly destroy a traditional rubber seal.

Superior Chemical Resistance

Beyond its mechanical design, the seal's material—Polytetrafluoroethylene (PTFE)—is almost chemically inert.

This allows it to operate in harsh environments with aggressive oils, acids, solvents, and other chemicals that would degrade or swell other materials.

Understanding the Trade-offs

While powerful, the PTFE seal's design is not universally superior. Its reliance on a dynamic effect introduces specific requirements and potential limitations.

Sensitivity to Shaft Condition

The hydrodynamic pumping action is highly dependent on a consistent interface between the seal lip and the shaft.

Any significant scratches, gouges, or imperfections on the shaft surface can disrupt this effect and create a leak path. A smooth, well-finished shaft is critical for proper function.

Installation Precision

PTFE is a much more rigid material than rubber. It has very little elasticity, meaning the seal can be damaged if not installed perfectly straight and with the correct tools.

Unlike a forgiving rubber seal, a PTFE seal cannot compensate for misalignment during installation.

Static Sealing Limitations

The primary sealing advantage—the pumping grooves—only functions when the shaft is rotating.

When the shaft is stationary, the seal relies solely on the light static tension of the lip. While effective in most cases, it may not provide the same robust static seal as a high-interference rubber lip in certain low-speed or intermittent applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the technology to the operational demands of your system.

- If your primary focus is high pressure or high speed: Choose the PTFE seal for its active hydrodynamic sealing, which is purpose-built for these conditions.

- If your primary focus is chemical compatibility: Choose the PTFE seal for its material inertness, ensuring longevity in harsh chemical environments.

- If your primary focus is cost-effectiveness on a non-critical, low-pressure application: A traditional rubber seal is often the more robust and forgiving choice, especially if shaft finish is not perfect.

By understanding the principles behind the design, you can confidently select the sealing technology that ensures the reliability and performance of your equipment.

Summary Table:

| Feature | PTFE Seal | Traditional Rubber Seal |

|---|---|---|

| Sealing Mechanism | Active hydrodynamic pumping | Passive static pressure |

| Max Pressure | Up to 3.0 MPa (double-lip) | ~0.03 MPa |

| Max Surface Speed | Up to 30 m/s | Limited by friction/heat |

| Chemical Resistance | Excellent (PTFE is inert) | Varies, can degrade |

| Key Limitation | Requires smooth shaft finish | Limited pressure/speed tolerance |

Need a PTFE Seal for Demanding Conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Our expertise is crucial for industries like semiconductor, medical, and laboratory, where reliability under high pressure, high speed, or corrosive environments is non-negotiable.

We provide custom fabrication from prototypes to high-volume orders, ensuring your seals are engineered for optimal performance.

Contact KINTEK today to discuss your specific sealing challenges and discover how our PTFE solutions can enhance your equipment's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments