In short, products directly related to headspace septa are the other essential components that form a complete, sealed sample container for analysis: specifically, the headspace vials that hold the sample and the aluminum crimp seals or caps that secure the septum to the vial. You can also source septa and seals as pre-assembled units.

The critical takeaway is that headspace septa are not standalone items but part of an integrated system. The vial, septum, and seal must be correctly matched to create the inert, leak-proof environment essential for accurate and repeatable headspace analysis.

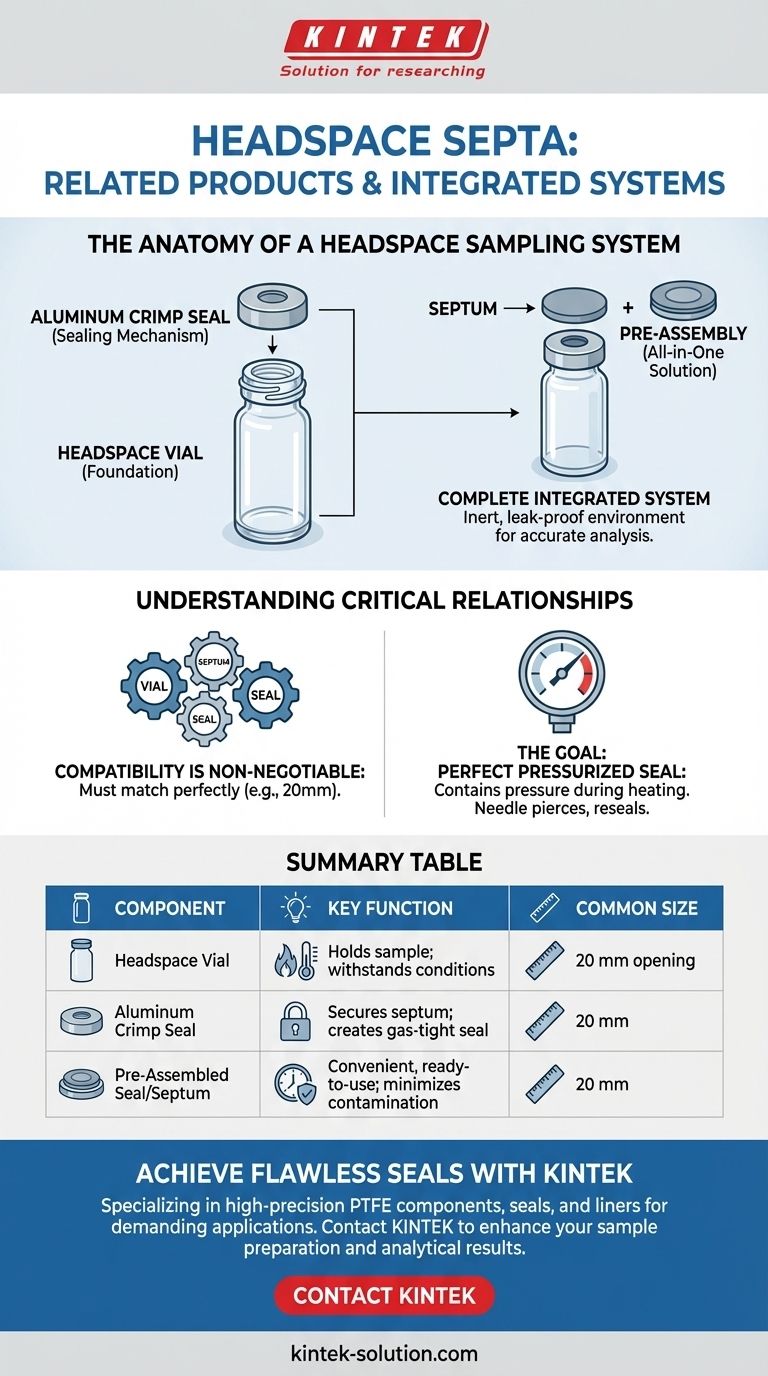

The Anatomy of a Headspace Sampling System

To understand the related products, it's best to visualize how a headspace sample is prepared and sealed. Each component plays a specific and vital role in maintaining sample integrity under heat and pressure.

The Foundation: Headspace Vials

A headspace vial is the glass container that holds your sample. These vials are specifically designed to withstand the high temperatures and internal pressures generated during the incubation stage of headspace analysis.

They feature a beveled or flat-bottomed shape for stability and uniform heating. The top of the vial has a specific "crimp top" finish designed to accept a sealing cap.

The Sealing Mechanism: Aluminum Crimp Seals

An aluminum crimp seal, or cap, is the component that physically holds the septum in place against the vial's opening.

Using a special tool called a crimper, the soft aluminum is tightly formed around the lip of the vial. This action creates a powerful, gas-tight seal that is crucial for preventing sample loss.

The All-in-One Solution: Pre-Assembled Seals with Septa

For convenience and to reduce the risk of contamination from handling, you can often purchase seals with septa already inserted.

These pre-assembled components streamline the sample preparation process, ensuring a perfect fit between the cap and the septum and saving valuable time in a high-throughput lab environment.

Understanding the Critical Relationships

Simply having the components is not enough; their compatibility and proper use are what guarantee reliable analytical results. The relationship between the vial, septum, and seal is the most common point of failure in headspace analysis.

Compatibility is Non-Negotiable

The diameter of the vial opening, the septum, and the cap must match perfectly. The most common size in headspace is 20 mm, so you would use a 20 mm vial with a 20 mm septum and a 20 mm aluminum crimp seal.

Using mismatched sizes will result in a failed seal, leading to sample loss, inaccurate pressure, and completely unreliable data.

The Goal: A Perfect, Pressurized Seal

Ultimately, all these related products work toward a single goal: creating a closed system.

During analysis, the vial is heated, causing volatile compounds from the sample to enter the gaseous phase (the "headspace"). This process builds pressure inside the vial. The seal created by the cap and septum must be strong enough to contain this pressure without leaking.

When the autosampler is ready, its needle pierces the septum to extract a portion of this pressurized gas for injection into the gas chromatograph. The septum must then reseal effectively to prevent contamination.

Making the Right Choice for Your Analysis

Choosing the correct consumables is the first step toward generating high-quality data.

- If your primary focus is high-throughput and convenience: Use pre-assembled aluminum crimp seals with pre-inserted septa to save time and minimize handling errors.

- If your primary focus is building a new analytical method: Start by ensuring your headspace vials and aluminum crimp seals are the correct, matching diameter (e.g., 20mm).

- If your primary focus is preventing analyte loss: Pay close attention to your crimping technique, as an under-crimped or over-crimped seal is the most common cause of leaks.

Understanding how these components function as a single unit empowers you to prepare samples with confidence and generate reliable results.

Summary Table:

| Component | Key Function | Common Size |

|---|---|---|

| Headspace Vial | Holds the sample; withstands heat and pressure. | 20 mm opening |

| Aluminum Crimp Seal | Secures the septum to the vial, creating a gas-tight seal. | 20 mm |

| Pre-Assembled Seal/Septum | Convenient, ready-to-use unit that minimizes contamination risk. | 20 mm |

Achieve Flawless Seals for Your Critical Analyses

Generating reliable data starts with a perfectly sealed sample vial. KINTEK specializes in manufacturing high-precision PTFE components, including seals and liners ideal for demanding applications in the semiconductor, medical, and laboratory industries.

We understand that compatibility and precision are non-negotiable for leak-proof performance. Whether you need custom prototypes or high-volume orders of reliable consumables, our expertise ensures your analytical systems operate with integrity.

Contact KINTEK today to discuss how our precision components can enhance your sample preparation and analytical results.

Visual Guide

Related Products

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What is the annual worldwide consumption of PTFE and its expected growth rate? A 5% CAGR Driven by Industrial Demand

- What is PTFE and how was it first manufactured? The Accidental Discovery of Teflon

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the temperature range in which PTFE maintains its properties? From -200°C to 260°C

- What is PTFE and what are its primary characteristics? The Ultimate High-Performance Polymer