To successfully machine PTFE, the recommended approach combines extremely sharp, uncoated carbide tools with precise CNC control. The core techniques—milling, turning, and drilling—must be adapted to manage PTFE's unique properties, specifically its low melting point, high thermal expansion, and tendency to deform under pressure.

The central challenge in machining PTFE is not material hardness, but heat and stress management. Success depends on minimizing frictional heat with sharp tooling and proper speeds, while also preventing the soft material from deforming due to excessive clamping or cutting forces.

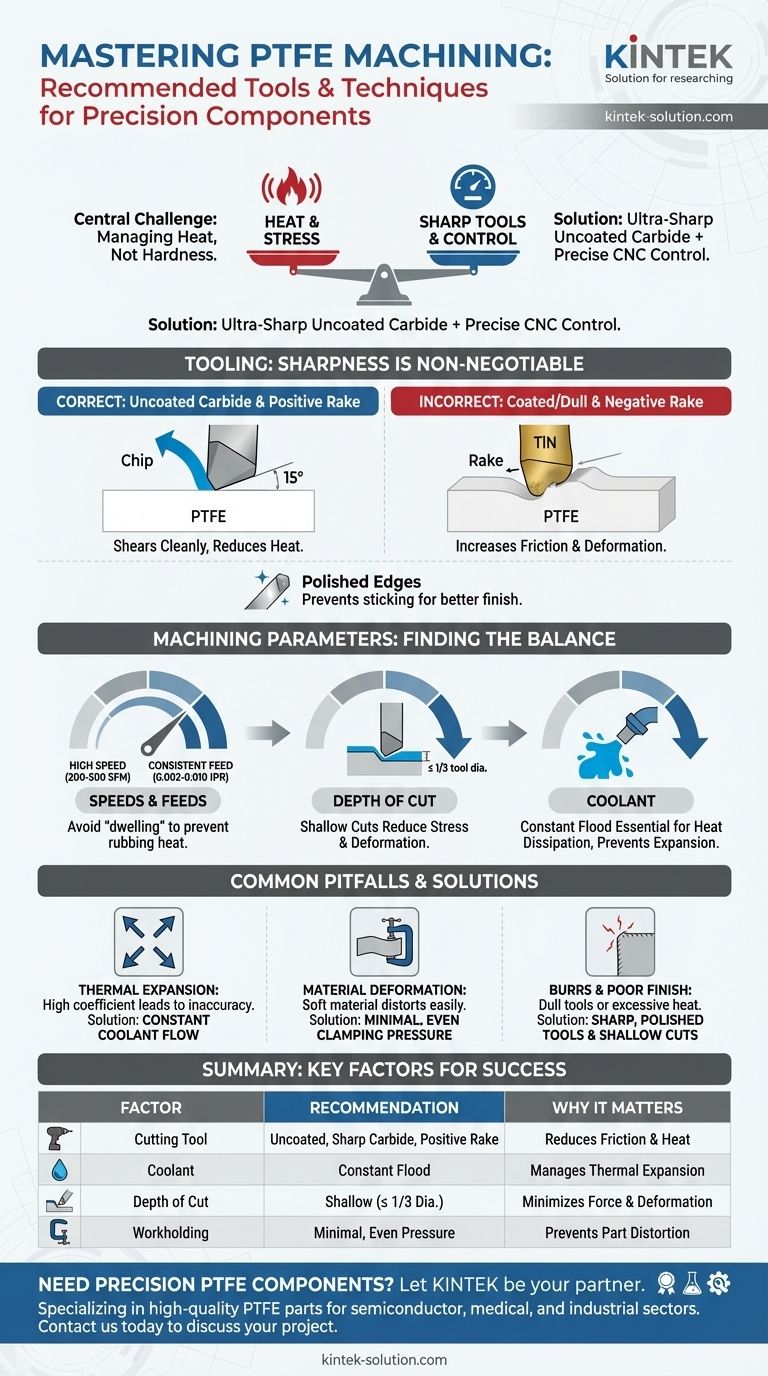

Selecting the Right Tooling: Sharpness is Non-Negotiable

The choice of cutting tool is the single most important factor in achieving a clean, dimensionally accurate result with PTFE. The goal is to shear the material cleanly rather than pushing or tearing it.

Why Uncoated Carbide is the Standard

Uncoated carbide-tipped or solid carbide tools are the preferred choice. Their ability to hold an extremely sharp edge reduces cutting forces and minimizes the frictional heat that causes PTFE to expand and deform.

Unlike with metals, coatings like Titanium Nitride (TiN) are detrimental here. They can increase friction, leading to more heat generation and material buildup on the tool edge.

The Critical Role of Tool Geometry

Proper tool geometry is essential for a clean cut. Tools should have a positive top rake angle, often between 0 and 15 degrees.

This geometry creates a shearing action that lifts the chip away from the workpiece. A neutral or negative rake angle would "plow" through the soft material, causing deformation, burrs, and a poor surface finish.

The Importance of Polished Edges

Using tools with highly polished cutting edges further reduces friction. This simple characteristic helps prevent the soft PTFE chips from sticking to the tool, ensuring a cleaner cut and better chip evacuation.

Mastering Machining Parameters for PTFE

Controlling the machine's parameters is about finding the balance between efficient material removal and heat management. An aggressive approach suitable for metals will lead to failure with PTFE.

Balancing Cutting Speeds and Feed Rates

PTFE can be machined at high cutting speeds (200-500 surface feet per minute), but this must be paired with an appropriate feed rate (0.002-0.010 inches per revolution).

The key is to avoid "dwelling," where the tool spins in one place without actively cutting. This rubbing action generates intense frictional heat. A consistent, moderate feed rate ensures the tool is always removing material and moving heat away with the chip.

The "Shallow Depth of Cut" Rule

To minimize cutting forces and heat, always use a shallow depth of cut. A common guideline is to not exceed one-third of the tool's diameter per pass.

This reduces the stress on the material, preventing it from deforming or being pulled into the cutter, which is a common problem with soft polymers.

The Necessity of Coolant

A constant flood of coolant is highly recommended. Its primary purpose is not lubrication but to dissipate heat as quickly as it's generated.

This prevents the PTFE part from expanding during machining, which would cause it to be undersized once it cools down to room temperature. Coolant also helps flush away the stringy chips typical of PTFE.

Understanding the Trade-offs and Common Pitfalls

Ignoring the unique properties of PTFE leads to predictable problems. Understanding these pitfalls is crucial for troubleshooting and process refinement.

The Problem of Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among polymers. Even a small temperature increase from friction will cause the material to expand significantly, leading to dimensional inaccuracy in the final part.

Avoiding Material Deformation

Because PTFE is soft, it can easily be distorted. Minimal clamping pressure is essential. Over-tightening a vise or chuck will compress the material, and the machined part will spring back out of tolerance once released. Use fixtures designed to distribute pressure evenly.

The Challenge of Burrs and Poor Finish

A poor surface finish and heavy burring are almost always caused by a dull tool, incorrect tool geometry, or excessive heat. Resharpen your tools regularly and confirm you are using a positive rake angle to ensure a clean shearing cut.

Making the Right Choice for Your Goal

Your specific objective will influence which parameters you prioritize.

- If your primary focus is high dimensional accuracy: Prioritize constant coolant flow and sharp, uncoated carbide tools to manage thermal expansion above all else.

- If your primary focus is excellent surface finish: Emphasize a very shallow depth of cut, polished tool edges, and a consistent feed rate to prevent tool marks and burrs.

- If your primary focus is avoiding material waste: Perfect your workholding strategy by using minimal, evenly distributed clamping pressure to prevent part deformation.

Ultimately, successful PTFE machining hinges on treating the material with precision, prioritizing heat management and sharpness over aggressive removal rates.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Cutting Tool | Uncoated, sharp carbide with positive rake | Reduces friction and heat; ensures a clean shear cut |

| Coolant | Constant flood | Manages thermal expansion for dimensional accuracy |

| Depth of Cut | Shallow (≤ 1/3 tool diameter) | Minimizes cutting forces and material deformation |

| Workholding | Minimal, even clamping pressure | Prevents part distortion from spring-back |

Need precision-machined PTFE components? Let KINTEK be your partner.

Machining PTFE to exact specifications requires expertise and the right approach. At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance of sharp tooling, precise parameters, and careful handling needed to produce dimensionally accurate, burr-free parts from prototypes to high-volume orders.

Contact us today to discuss your project requirements and leverage our expertise in custom PTFE fabrication. Get in touch →

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability