In short, the operational temperature range for an encapsulated O-ring is a composite figure determined by its components, typically falling between -60°C (-75°F) and 260°C (500°F). The specific outer jacket material (FEP or PFA) dictates the maximum temperature, while the inner elastomer core (Silicone or Viton) dictates the minimum. This dual-material construction is key to their performance in extreme environments.

The most critical takeaway is that you are not selecting a single material, but a system. The outer fluoropolymer jacket provides chemical and high-temperature resistance, but the inner elastomer core dictates the seal's flexibility and low-temperature capability. Understanding this interplay is essential for a reliable seal.

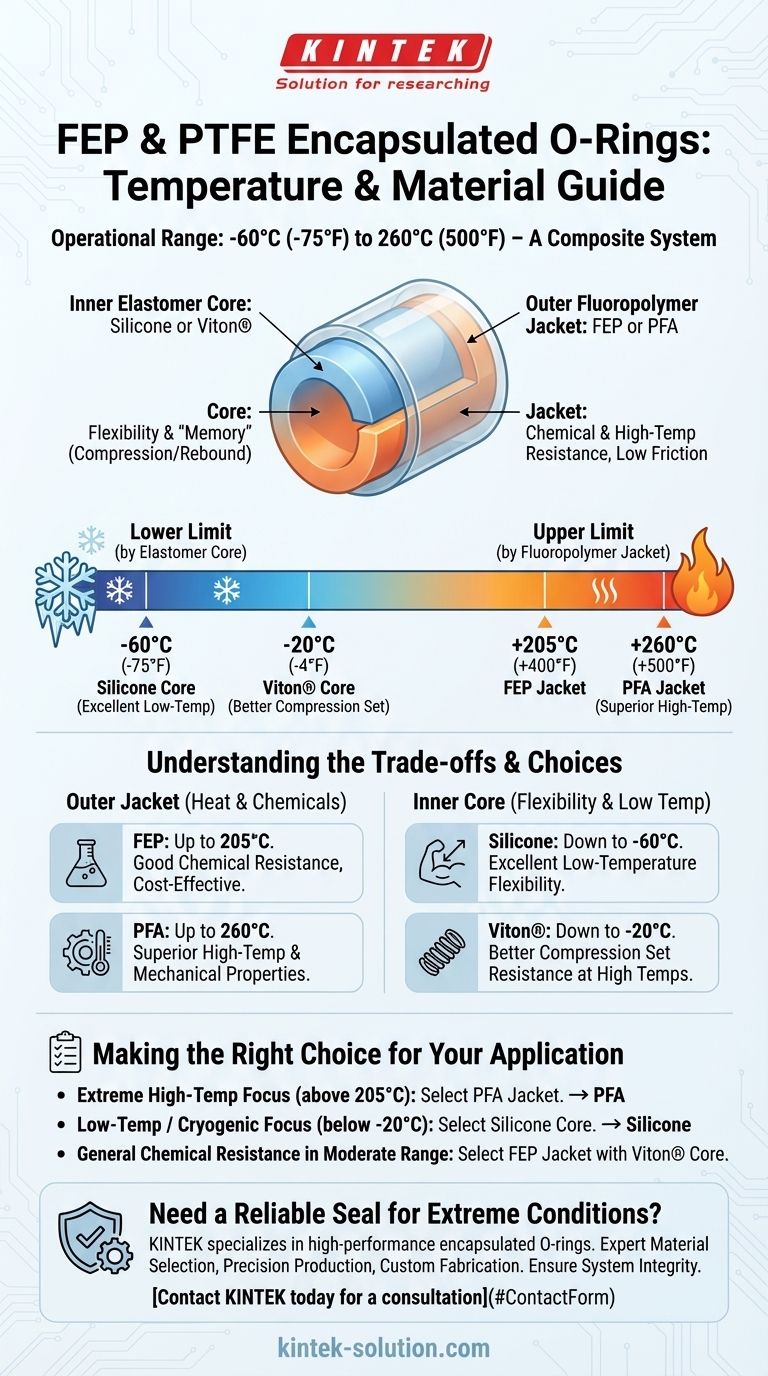

The Anatomy of an Encapsulated O-Ring

To understand the temperature limits, you must first understand the construction. These seals are designed to combine the best properties of two different material classes.

The Outer Shield: The Fluoropolymer Jacket

The seamless outer layer, or jacket, is made from a highly inert fluoropolymer, most commonly FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy Alkanes).

This jacket provides exceptional resistance to chemicals, solvents, and abrasion. It also creates a low-friction surface.

The Inner Core: The Elastomer Engine

The inner core is a solid elastomer O-ring that provides the physical properties of compression and rebound—what engineers call "memory."

This core gives the seal its flexibility and ability to maintain pressure. The two most common core materials are Silicone and Viton® (FKM).

Deconstructing the Temperature Range

The overall temperature rating is not a single number but a window defined by the limits of both the jacket and the core.

The Upper Limit: Defined by the FEP or PFA Jacket

The maximum operating temperature is set by the outer encapsulation material.

- FEP jackets have a maximum continuous service temperature of approximately 205°C (400°F).

- PFA jackets can withstand higher temperatures, up to 260°C (500°F), and offer slightly better mechanical properties.

Exceeding these limits can cause the jacket to soften, deform, or decompose, leading to seal failure.

The Lower Limit: Governed by the Elastomer Core

The minimum operating temperature is determined by the inner core material, as this is the point where it loses its elasticity and can no longer maintain a seal.

- A Silicone core allows for excellent low-temperature performance, typically down to -60°C (-75°F).

- A Viton® (FKM) core has a higher low-temperature limit, generally around -20°C (-4°F), but offers better resistance to compression set at elevated temperatures.

Understanding the Trade-offs and Limitations

While versatile, encapsulated O-rings are not a universal solution. Their unique construction introduces specific compromises that are critical to consider.

Reduced Elasticity

The fluoropolymer jacket is inherently stiffer than a standard rubber O-ring. This means they require more force to compress and are less forgiving of surface imperfections in the sealing groove.

Susceptibility to Damage

The thin encapsulation is the primary barrier against chemical attack. If this jacket is scratched or nicked during installation, the aggressive media can reach and destroy the inner elastomer core, causing a premature failure.

Higher Compression Set

Compared to high-performance elastomers alone, encapsulated O-rings have a higher tendency to permanently deform after being compressed for long periods, especially under thermal cycling. They do not "spring back" as effectively.

Making the Right Choice for Your Application

To select the correct seal, you must match the materials to your primary operational challenge.

- If your primary focus is extreme high-temperature resistance (above 205°C): You must select an O-ring with a PFA jacket.

- If your primary focus is low-temperature or cryogenic performance (below -20°C): Your only viable option is an O-ring with a Silicone core.

- If your primary focus is general chemical resistance in a moderate temperature range: An FEP jacket with a Viton® core is the most common and cost-effective configuration.

Ultimately, choosing the right encapsulated O-ring requires you to look beyond a single temperature rating and consider the distinct roles of the core and the jacket.

Summary Table:

| Component | Material | Temperature Range | Key Characteristic |

|---|---|---|---|

| Outer Jacket | FEP | Up to 205°C (400°F) | Good chemical resistance, cost-effective |

| Outer Jacket | PFA | Up to 260°C (500°F) | Superior high-temp & mechanical properties |

| Inner Core | Silicone | Down to -60°C (-75°F) | Excellent low-temperature flexibility |

| Inner Core | Viton® (FKM) | Down to -20°C (-4°F) | Better compression set resistance at high temps |

Need a Reliable Seal for Extreme Conditions?

Choosing the right encapsulated O-ring is critical for performance and safety in demanding semiconductor, medical, and industrial applications. The interplay between the fluoropolymer jacket and elastomer core defines the seal's capabilities.

KINTEK specializes in manufacturing high-performance PTFE and FEP components, including custom encapsulated O-rings. We provide:

- Expert Material Selection: Guidance to match the perfect jacket (FEP/PFA) and core (Silicone/Viton®) combination for your specific temperature and chemical requirements.

- Precision Production: Consistent, high-quality seals built for reliability.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

Ensure your system's integrity. Let our experts help you select or custom-design the perfect seal for your application.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime