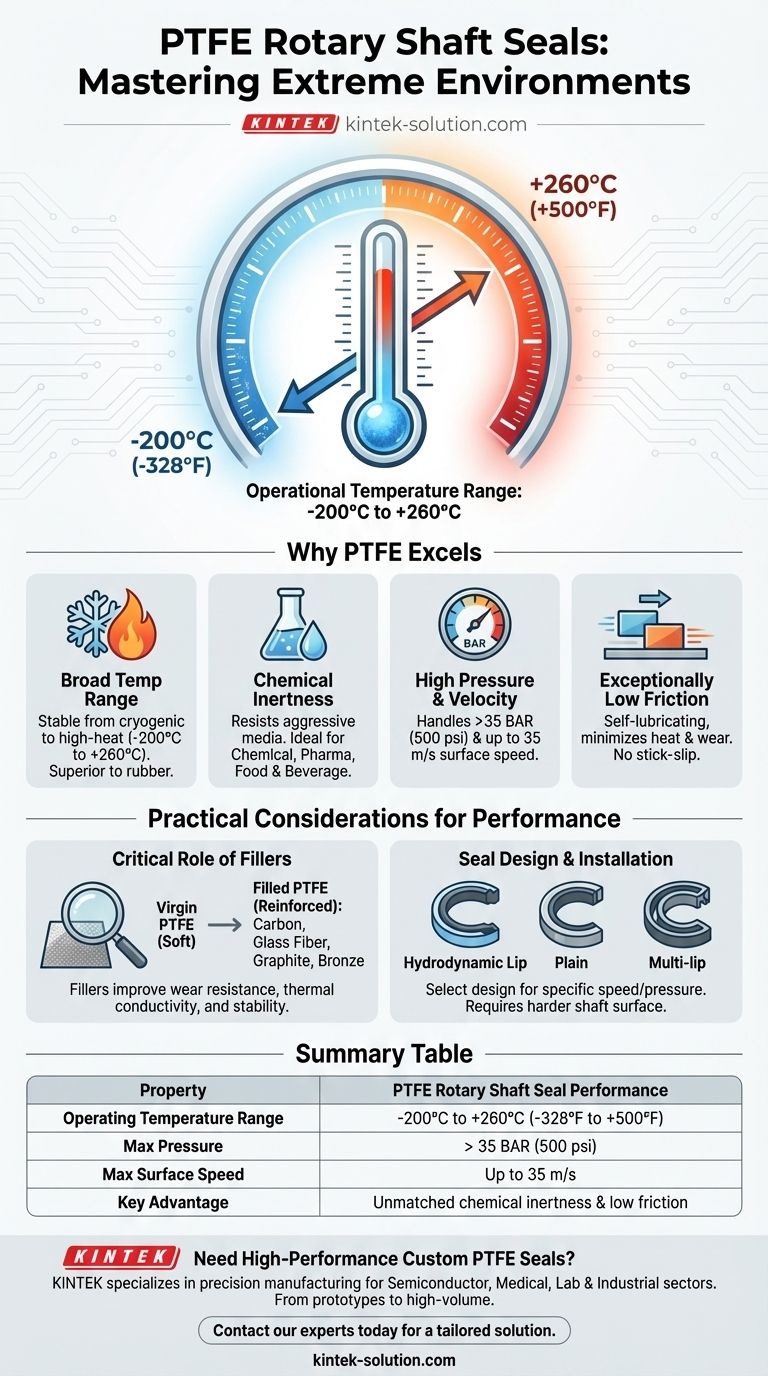

In practice, PTFE rotary shaft seals reliably operate in a broad temperature range, typically from -200°C to +260°C (-328°F to +500°F). While the raw PTFE material can theoretically withstand a wider spectrum, this operational range reflects real-world performance in dynamic applications where pressure, speed, and material composition are critical factors.

The true advantage of PTFE is not just its temperature tolerance but its unique combination of thermal stability, chemical inertness, and low friction. Understanding this synergy is the key to leveraging these seals effectively in demanding environments where traditional elastomeric seals would fail.

Why PTFE Excels in Extreme Environments

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer chosen for sealing applications that push beyond the limits of conventional materials. Its molecular structure gives it a set of properties that make it exceptionally durable and reliable.

Unpacking the Operating Temperature Range

The broad temperature range of -200°C to +260°C allows PTFE seals to function in everything from cryogenic processes to high-heat industrial machinery. Unlike rubber seals that can become brittle at low temperatures or degrade at high temperatures, PTFE remains stable and functional.

Superior Chemical Inertness

PTFE is chemically inert to almost all industrial chemicals and lubricants. This makes it the default choice for applications in chemical processing, pharmaceuticals, and food and beverage, where aggressive media would quickly destroy other sealing materials.

High Pressure and Velocity Tolerance

These seals are engineered for demanding dynamic conditions. They can handle pressures exceeding 35 BAR (500 psi) and surface speeds up to 35 m/s, a significant advantage over many elastomeric seals that have much lower pressure and speed limits.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property minimizes heat generation at the contact point, reduces torque requirements, and prevents stick-slip behavior during startup.

Understanding the Practical Considerations

While PTFE's base properties are impressive, the performance of a final seal is heavily influenced by its specific composition and design. Simply choosing "PTFE" is not enough; you must consider the complete system.

The Critical Role of Fillers

Pure, or "virgin," PTFE is relatively soft and can be prone to cold flow (creep) under load. To enhance its mechanical properties, fillers like carbon, glass fiber, graphite, or bronze are added to the base material. These fillers improve wear resistance, thermal conductivity, and dimensional stability, which are essential for a long-lasting dynamic seal.

Seal Design and Configuration

PTFE seals come in various designs, such as hydrodynamic, plain, and multi-lip configurations. A hydrodynamic lip, for example, features etched aids that actively pump lubricant back into the system, reducing friction and wear at high speeds. The choice of design directly impacts the seal's performance under specific speed, pressure, and lubrication conditions.

Installation and System Hardness

Proper installation is crucial for any seal, and PTFE is no exception. However, because filled PTFE compounds can be more abrasive than rubber, they often require a harder and smoother shaft surface finish to ensure optimal performance and prevent premature wear of both the seal and the shaft.

Selecting the Right PTFE Seal for Your Application

Choosing the correct seal requires matching the material compound and design to your primary operational challenge.

- If your primary focus is extreme temperatures: Verify the specific temperature rating of the chosen PTFE compound, as fillers can slightly alter the operational limits of the base polymer.

- If your primary focus is high speed or pressure: Select a seal with a design engineered for dynamic stress, such as a hydrodynamic lip, and a filler (like carbon or bronze) that enhances strength and heat dissipation.

- If your primary focus is aggressive chemical compatibility: Ensure both the base PTFE and any filler materials are fully inert to the specific media in your system to prevent degradation.

Ultimately, viewing the seal as an integral part of a complete engineering system is the surest path to reliability and performance.

Summary Table:

| Property | PTFE Rotary Shaft Seal Performance |

|---|---|

| Operating Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Max Pressure | > 35 BAR (500 psi) |

| Max Surface Speed | Up to 35 m/s |

| Key Advantage | Unmatched chemical inertness & low friction |

Need a PTFE Seal for Extreme Temperatures or Aggressive Chemicals?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to meet your exact requirements.

Contact our experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems