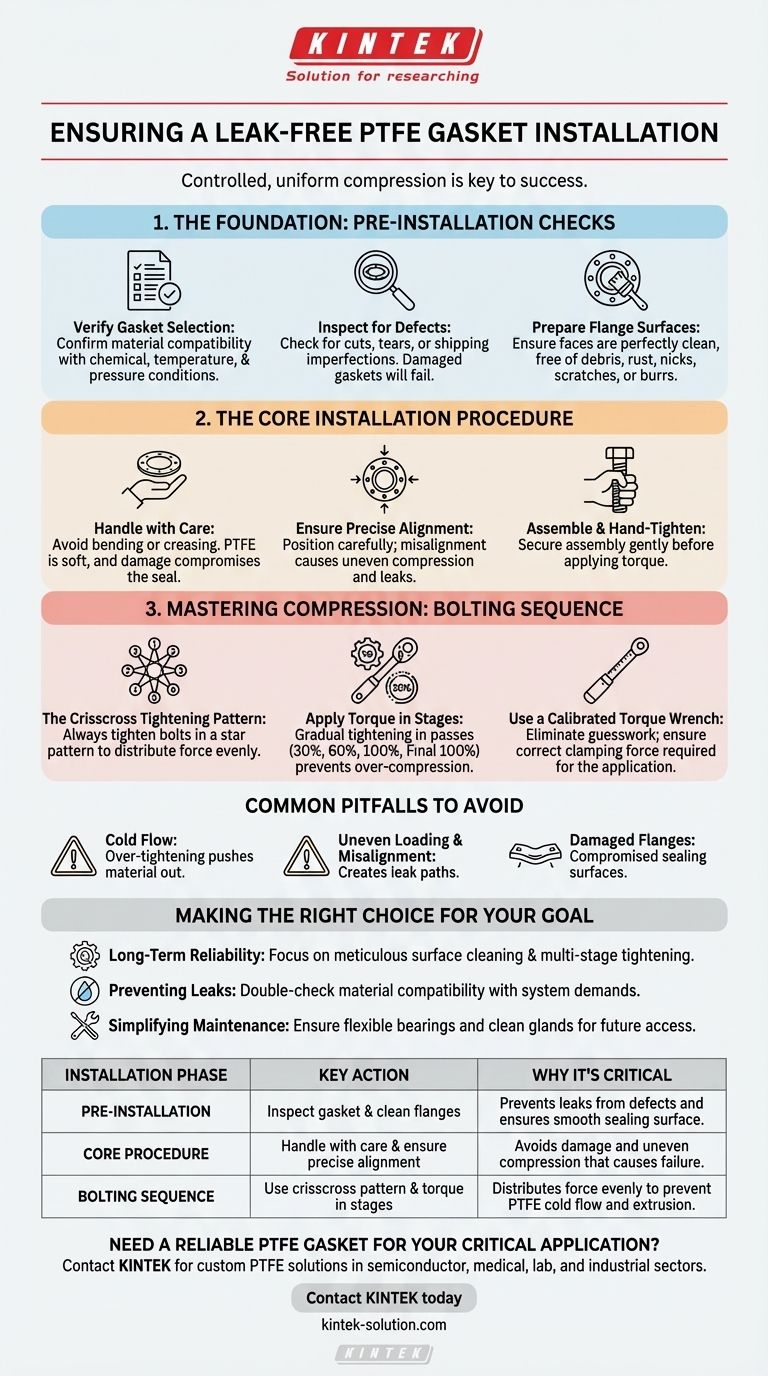

To properly install a PTFE gasket, you must execute a systematic process that includes meticulous surface preparation, careful gasket handling and alignment, and the precise application of even clamping force. This is achieved by following a specific, multi-stage bolt-tightening sequence to achieve a durable, leak-free seal.

The success of a PTFE gasket installation hinges on one central principle: achieving a controlled, uniform compression. Unlike metal gaskets, PTFE seals by flowing into the imperfections of the flange surfaces, and improper or uneven force will cause it to deform, extrude, and ultimately fail.

The Foundation: Pre-Installation Checks

Before the gasket is ever placed, the success of the seal has already been partially determined. Proper preparation of the sealing environment is non-negotiable.

Verify the Gasket Selection

First, confirm you have the correct gasket. Consider the system's chemical compatibility, temperature range, and pressure conditions to ensure the selected PTFE material can withstand the operational environment.

Inspect the Gasket for Defects

Carefully examine the new gasket for any cuts, tears, or imperfections from shipping or handling. A damaged gasket will never provide a reliable seal.

Prepare the Flange Surfaces

The condition of the flange faces is critical. They must be perfectly clean and free of any debris, rust, or old gasket material. Most importantly, check for and remove any nicks, scratches, or burrs, as these can create leak paths or damage the soft PTFE material.

The Core Installation Procedure

With the foundation set, the installation itself requires precision and a gentle hand. Force is the enemy of a successful PTFE gasket seal.

Handle with Care

PTFE is a relatively soft material. Avoid bending, creasing, or dropping the gasket. Any damage to the sealing line can compromise the entire installation.

Ensure Precise Alignment

Position the gasket carefully, ensuring it is perfectly centered on the flange sealing surface. Misalignment is a primary cause of uneven compression and subsequent leaks. Alignment tools can be helpful for larger or more critical applications.

Assemble and Hand-Tighten

Bring the flanges together carefully, ensuring they meet parallel to each other without damaging the gasket. Insert the bolts and hand-tighten them to secure the assembly in place before applying torque.

Mastering Compression: The Bolting Sequence

This is the most critical phase of the installation. How you tighten the bolts directly controls the gasket's ability to seal effectively.

The Crisscross Tightening Pattern

Never tighten adjacent bolts sequentially. Always use a crisscross or star pattern to distribute the clamping force evenly across the entire flange surface. This prevents one side from being over-compressed while the other remains too loose.

Apply Torque in Stages

Even pressure is achieved by applying torque gradually. A standard practice is to tighten in three to four distinct passes, following the crisscross pattern each time.

- Pass 1: Tighten to approximately 30% of the final required torque value.

- Pass 2: Tighten to approximately 60% of the final torque.

- Pass 3: Tighten to 100% of the final torque.

- Final Pass: After a short period (15-30 minutes), perform one final pass at 100% torque to account for any initial material settling.

Use a Calibrated Torque Wrench

Guesswork is not acceptable for critical seals. Using a properly calibrated torque wrench is the only way to ensure you are applying the correct, specified clamping force required for your specific application.

Common Pitfalls to Avoid

Understanding why PTFE gaskets fail is key to ensuring they don't. The material's unique properties create specific challenges.

The Problem of "Cold Flow"

PTFE's primary weakness is cold flow, or creep, where the material slowly deforms and is pushed out of the flange under excessive pressure. This is almost always caused by over-tightening the bolts. Following specified torque values is the only way to prevent this.

Uneven Loading and Misalignment

If the flanges are not parallel or the gasket is off-center, the clamping force will be concentrated in one area. This localized high pressure will cause cold flow, while the low-pressure areas will create an immediate leak path.

Damaged or Warped Flanges

A perfect gasket and a perfect installation procedure will fail if the sealing surfaces themselves are compromised. A warped or deeply scratched flange face cannot be sealed by a standard PTFE gasket.

Making the Right Choice for Your Goal

Your installation priority should guide your focus during the process.

- If your primary focus is long-term reliability in a critical system: Meticulously clean and inspect the flange surfaces and use a calibrated torque wrench to follow a multi-stage tightening sequence without deviation.

- If your primary focus is preventing persistent, hard-to-diagnose leaks: Double-check that the gasket material itself is rated for the specific chemical, temperature, and pressure demands of your system before starting the installation.

- If your primary focus is simplifying future maintenance: Ensure all equipment bearings are flexible and glands are clean and free of burrs to make subsequent gasket removal and replacement far more efficient.

A methodical and precise installation process is what transforms a simple component into a highly reliable sealing solution.

Summary Table:

| Installation Phase | Key Action | Why It's Critical |

|---|---|---|

| Pre-Installation | Inspect gasket & clean flange surfaces | Prevents leaks from defects and ensures a smooth sealing surface |

| Core Procedure | Handle with care and ensure precise alignment | Avoids damage and uneven compression that causes failure |

| Bolting Sequence | Use a crisscross pattern and torque in stages | Distributes force evenly to prevent PTFE cold flow and extrusion |

Need a Reliable PTFE Gasket for Your Critical Application?

A flawless installation starts with a high-quality, precision-manufactured gasket. KINTEK specializes in custom PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. We ensure our products meet the exact specifications required for your system's chemical, temperature, and pressure demands.

Let us provide the durable, leak-free sealing solution you need—from prototypes to high-volume orders.

Contact KINTEK today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability