When machining Polytetrafluoroethylene (PTFE), coolant's primary role is not lubrication but rather thermal and chip management. Its main functions are to dissipate heat to prevent the material's significant thermal expansion and to clear away fine chips that can otherwise melt and degrade the surface finish. This ensures the final part maintains its dimensional stability and accuracy.

The core challenge with PTFE isn't high cutting forces, but its extreme sensitivity to heat and its tendency to produce fine, sticky chips. The right "coolant"—often just compressed air or a light mist—is critical for managing these properties to achieve a precise, clean finish.

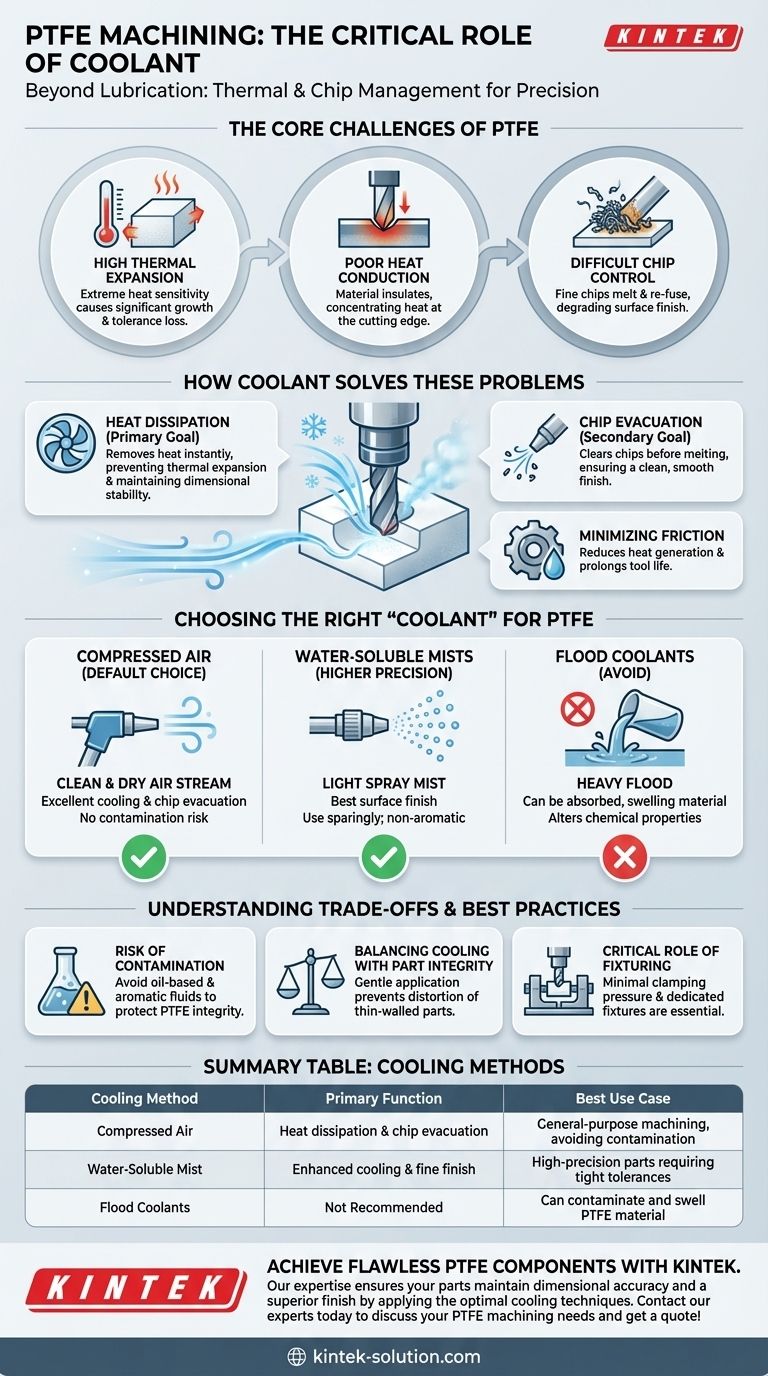

The Core Challenges of Machining PTFE

To understand the role of coolant, we must first understand the unique properties of the material itself. PTFE presents several challenges that a proper cooling strategy directly addresses.

High Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among polymers. Even a small amount of heat generated from tool friction will cause the material to expand significantly, making it impossible to hold tight tolerances.

Poor Heat Conduction

The material is an excellent thermal insulator. This means it doesn't conduct heat away from the cutting zone effectively, causing heat to concentrate right at the tool edge and on the part's surface.

Difficult Chip Control

Machining PTFE generates fine, stringy, or powdery chips. Due to the material's low melting point, these chips can easily melt from friction, sticking to the tool or re-fusing to the workpiece, which severely degrades the surface finish.

How Coolant Solves These Problems

A cooling medium in PTFE machining is less about lubricity and more about directly countering the material's inherent challenges.

The Primary Goal: Heat Dissipation

The most critical function of a coolant is to remove heat from the cutting zone at the moment it's generated. By preventing heat buildup, the coolant stops the material from expanding, which is the single most important factor in maintaining dimensional accuracy.

The Secondary Goal: Chip Evacuation

A constant stream of air or mist physically blows the fine chips away from the cutting edge. This prevents them from melting, clogging the tool, or damaging the part's surface, resulting in a much cleaner and smoother cut.

Minimizing Friction

While not the primary goal, a light lubricant does reduce friction between the tool and the material. This further minimizes heat generation and can help prolong the life of the cutting tool.

Choosing the Right "Coolant" for PTFE

The term "coolant" is used loosely with PTFE. Traditional flood coolants used for metals are often unsuitable and can even contaminate the material.

Compressed Air: The Default Choice

For most applications, a steady stream of clean, dry compressed air is the ideal choice. It provides excellent cooling and chip evacuation without any risk of chemical contamination or material absorption.

Water-Soluble Mists: For Higher Precision

For achieving the best possible surface finish and holding extremely close tolerances, a non-aromatic, water-soluble coolant applied as a light spray mist is recommended. The key is to use it sparingly to prevent saturating the workpiece.

Flood Coolants: What to Avoid

Heavy flood cooling is almost always incorrect for PTFE. Oil-based coolants, in particular, should be avoided as they can be absorbed by the porous material, causing it to swell and altering its chemical properties.

Understanding the Trade-offs and Best Practices

Applying coolant correctly is part of a larger strategy for successfully machining soft materials.

Risk of Material Contamination

PTFE's integrity can be compromised by chemical absorption. Always ensure any liquid lubricant used is specified as "non-aromatic" and water-soluble to prevent unintended changes to the material.

Balancing Cooling with Part Integrity

While cooling is essential, excessive air pressure or a heavy liquid stream can physically distort thin-walled or delicate PTFE components. The application must be firm enough to be effective but gentle enough to avoid warping the part.

The Critical Role of Fixturing

No cooling strategy can compensate for poor workholding. PTFE must be held in fixtures that provide adequate support with minimal clamping pressure. Specialized fixtures designed for soft plastics are essential to prevent the part from being distorted before a tool ever touches it.

Selecting Your Cooling Strategy

Your choice of coolant should be directly tied to the requirements of the finished part.

- If your primary focus is general-purpose machining or avoiding contamination: Use clean, dry compressed air as your first and best option.

- If your primary focus is achieving the highest surface finish and tightest tolerances: Use a light spray mist of a non-aromatic, water-soluble coolant.

- If you are working with very thin or delicate parts: Reduce coolant pressure and ensure your fixturing provides full support with minimal clamping force to prevent distortion.

Ultimately, treating your cooling medium as a precision tool for thermal and chip management is the key to successfully machining PTFE.

Summary Table:

| Cooling Method | Primary Function | Best Use Case |

|---|---|---|

| Compressed Air | Heat dissipation & chip evacuation | General-purpose machining, avoiding contamination |

| Water-Soluble Mist | Enhanced cooling & fine finish | High-precision parts requiring tight tolerances |

| Flood Coolants | Not Recommended | Can contaminate and swell PTFE material |

Achieve Flawless PTFE Components with KINTEK

Struggling with thermal expansion or poor surface finish on your PTFE parts? The right cooling strategy is crucial. At KINTEK, we specialize in the precision machining of PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, and laboratory industries.

Our expertise ensures your parts maintain dimensional accuracy and a superior finish by applying the optimal cooling techniques. Let us handle your project from prototype to high-volume production.

Contact our experts today to discuss your PTFE machining needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability