At its core, Teflon coatings meet stringent regulations set by the U.S. Food and Drug Administration (FDA) for materials intended for direct food contact. This compliance is the fundamental requirement that allows Teflon's use in food processing equipment, ensuring the material is safe and suitable for applications where it will touch food products directly.

The key takeaway is not just that Teflon coatings are FDA-compliant, but that this compliance unlocks their powerful non-stick and easy-clean properties to solve critical efficiency, quality, and maintenance challenges throughout the food production industry.

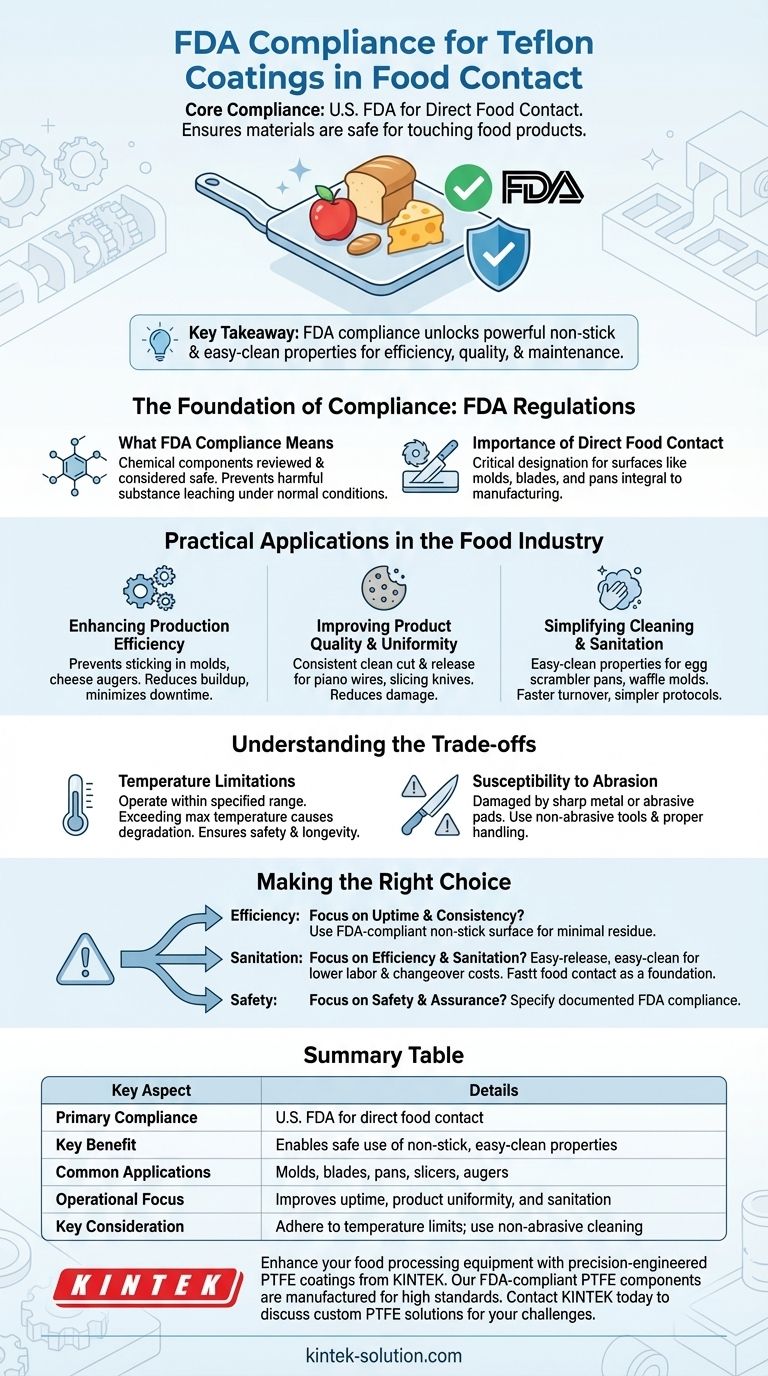

The Foundation of Compliance: FDA Regulations

Understanding what FDA compliance entails is crucial for any professional specifying materials for food-grade applications. It provides the necessary assurance of safety and suitability.

What FDA Compliance Means

FDA compliance for food contact materials means that the chemical components used in the Teflon coating formulation have been reviewed and are considered safe for their intended use. This ensures that the coating will not leach harmful substances into the food it touches under normal operating conditions.

This is not a one-time certification for the brand "Teflon" but rather a compliance standard that the specific coating formulations must meet.

The Importance of Direct Contact Approval

The designation for direct food contact is the most critical aspect of this regulation. It explicitly permits the coating to be used on surfaces like molds, blades, and pans that are integral to the food manufacturing process, rather than just on external machinery components.

Practical Applications in the Food Industry

The true value of FDA compliance is seen in how it enables Teflon to be deployed in diverse food processing environments to solve specific operational problems.

Enhancing Production Efficiency

In applications like sugar cube molds or cheese augers, the non-stick surface prevents the product from adhering to the equipment. This reduces buildup, minimizes downtime for cleaning, and ensures a more continuous and efficient production flow.

Improving Product Quality and Uniformity

For cookie manufacturers using Teflon-coated piano wires or potato chip producers using coated slicing knives, the benefit is consistency. The coating ensures a clean cut and release every time, reducing product damage and ensuring a more uniform final product.

Simplifying Cleaning and Sanitation

Fast-food restaurants and industrial bakeries use Teflon on items like egg scrambler pans and waffle molds. The easy-clean properties dramatically reduce cleaning time and effort, allowing for faster equipment turnover and simpler sanitation protocols.

Understanding the Trade-offs

While highly effective, specifying any material requires an objective understanding of its operational limits. These considerations are key to successful implementation.

Temperature Limitations

Teflon coatings have a maximum service temperature. Exceeding this limit can cause the coating to degrade. It is essential to operate equipment within the specified temperature range to ensure both food safety and the coating's longevity.

Susceptibility to Abrasion

The non-stick surface can be damaged by sharp metal utensils or harsh abrasive cleaning pads. Proper handling protocols and the use of non-abrasive cleaning tools are necessary to protect the integrity of the coating and extend its service life.

Making the Right Choice for Your Application

Selecting a coating goes beyond its basic properties; it's about matching it to a specific operational goal.

- If your primary focus is production uptime and consistency: The non-stick surface, backed by FDA compliance, is your key to minimizing residue buildup and ensuring uniform product handling.

- If your primary focus is operational efficiency and sanitation: The easy-release and easy-clean characteristics of the coating directly reduce labor costs associated with cleaning and equipment changeovers.

- If your primary focus is material safety and regulatory assurance: Specifying a coating with documented FDA compliance for direct food contact is a foundational step in building safe and reliable food processing equipment.

By understanding its regulatory standing, you can confidently leverage Teflon's properties to enhance your food processing operations.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Compliance | U.S. FDA for direct food contact |

| Key Benefit | Enables safe use of non-stick, easy-clean properties |

| Common Applications | Molds, blades, pans, slicers, augers |

| Operational Focus | Improves uptime, product uniformity, and sanitation |

| Key Consideration | Adhere to temperature limits; use non-abrasive cleaning |

Enhance your food processing equipment with precision-engineered PTFE coatings from KINTEK.

Our FDA-compliant PTFE (Teflon) components are manufactured to the highest standards for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring your equipment benefits from superior non-stick performance, improved product quality, and reduced maintenance.

Contact KINTEK today to discuss how our custom PTFE solutions can solve your specific food processing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance