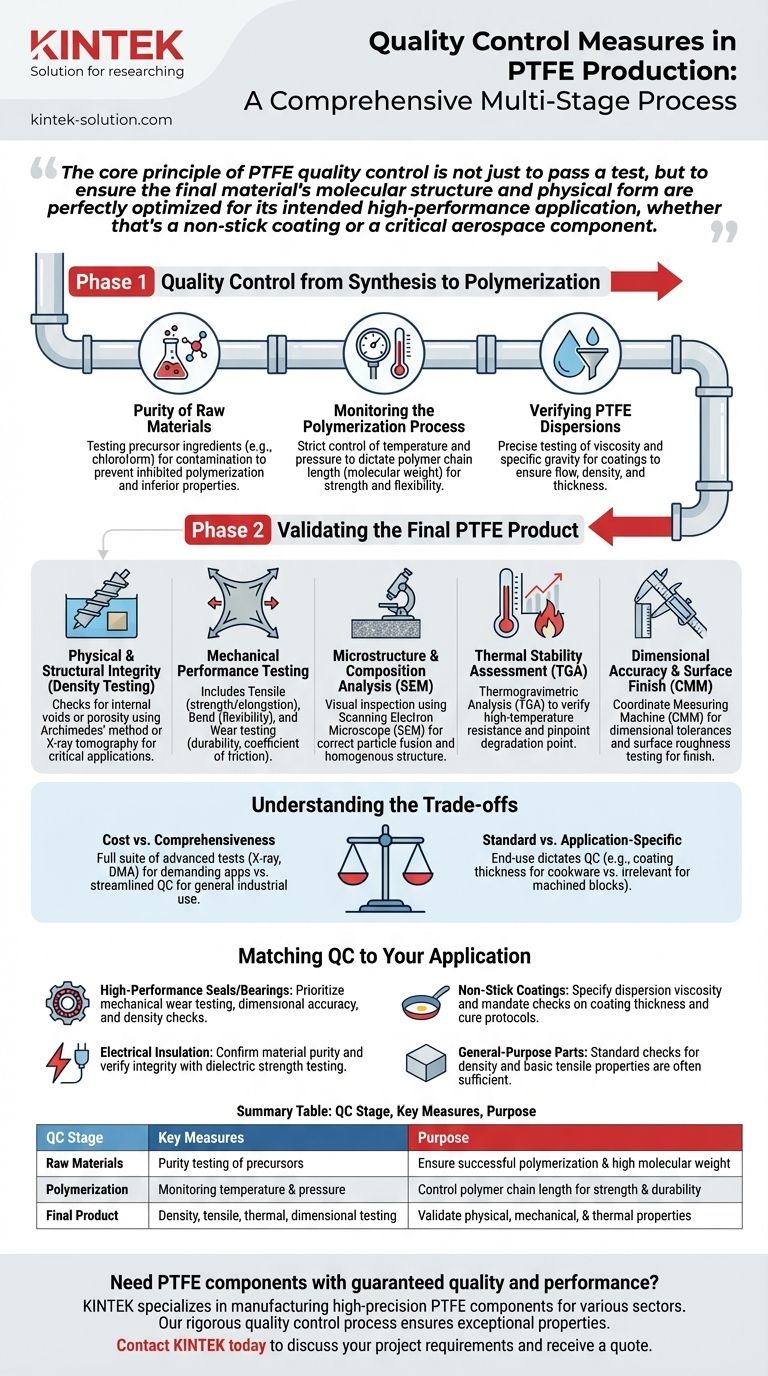

In short, quality control in Polytetrafluoroethylene (PTFE) production is a comprehensive, multi-stage process. It begins with verifying the purity of chemical ingredients, moves to tightly monitoring polymerization conditions like temperature and pressure, and concludes with a rigorous battery of tests on the final product to validate its physical, mechanical, and thermal properties.

The core principle of PTFE quality control is not just to pass a test, but to ensure the final material's molecular structure and physical form are perfectly optimized for its intended high-performance application, whether that's a non-stick coating or a critical aerospace component.

Quality Control from Synthesis to Polymerization

The integrity of the final PTFE product is determined long before it takes its final shape. Quality control starts at the very beginning of the chemical synthesis process and continues through the creation of the raw polymer.

Purity of Raw Materials

The entire process begins with creating the tetrafluoroethylene (TFE) monomer. Quality control at this stage involves testing the purity of precursor ingredients like chloroform and chlorodifluoromethane.

Any contamination can inhibit the polymerization reaction, leading to a lower molecular weight and inferior material properties in the final product.

Monitoring the Polymerization Process

During polymerization, TFE gas is converted into solid PTFE polymer chains. Strict monitoring of temperature and pressure is critical.

These variables directly control the length of the polymer chains (molecular weight), which in turn dictates the material's final strength, flexibility, and durability.

Verifying PTFE Dispersions

For applications like coatings, PTFE is produced as a liquid dispersion. QC measures for these dispersions include precise testing of viscosity and specific gravity.

These tests ensure the dispersion will flow and coat a surface correctly and that the final cured layer will have the right density and thickness.

Validating the Final PTFE Product

Once PTFE has been polymerized and processed into a solid form (e.g., a rod, sheet, or molded part), a second phase of testing begins to validate its performance characteristics against engineering specifications.

Physical and Structural Integrity

Density testing is the most fundamental QC check for solid PTFE. It is often performed using Archimedes’ method and is used to identify internal voids or porosity, which can compromise mechanical strength and dielectric properties.

For critical applications, advanced methods like X-ray tomography can be used to create a 3D map of internal density variations.

Mechanical Performance Testing

To ensure the material can withstand real-world stress, it undergoes a series of mechanical tests.

These include tensile testing to measure strength and elongation, bend testing to assess flexibility, and wear testing to determine its durability and coefficient of friction for bearing and seal applications.

Microstructure and Composition Analysis

Using tools like a Scanning Electron Microscope (SEM), technicians can visually inspect the material's internal microstructure.

This analysis confirms that the polymer particles have fused correctly during processing, ensuring a uniform and homogenous material free from structural defects.

Thermal Stability Assessment

A key advantage of PTFE is its high-temperature resistance. Thermogravimetric Analysis (TGA) is used to verify this property.

TGA measures the material's weight change as it is heated, pinpointing the exact temperature at which it begins to degrade. This confirms the material's safe operating temperature range.

Dimensional Accuracy and Surface Finish

For precision-engineered components, physical dimensions are paramount. A Coordinate Measuring Machine (CMM) is used to confirm that parts are within strict dimensional tolerances.

Additionally, surface roughness testing ensures the finish is appropriate for the application, especially for low-friction surfaces in seals or bearings.

Understanding the Trade-offs

Implementing a quality control program requires balancing rigor with practicality. Not every application demands the same level of scrutiny.

Cost vs. Comprehensiveness

A full suite of advanced tests (like X-ray tomography or Dynamic Mechanical Analysis) is expensive and time-consuming. These are typically reserved for the most demanding applications in fields like aerospace, medical devices, or semiconductor manufacturing.

For general industrial use, a more streamlined QC process focusing on density, tensile properties, and dimensional accuracy is often sufficient.

Standard vs. Application-Specific Testing

The end-use application dictates the most important QC measures. For example, a manufacturer using a Teflon™ branded coating for cookware must adhere to specific guidelines for coating thickness and baking temperature protocols.

This is an application-specific control that would be irrelevant for a solid PTFE block intended for machining into industrial seals. The QC plan must align with the product's function.

Matching QC to Your Application

The right quality control measures depend entirely on the performance demands of your project.

- If your primary focus is high-performance seals or bearings: Prioritize mechanical wear testing, dimensional accuracy (CMM), and density checks to ensure longevity and a proper fit.

- If your primary focus is electrical insulation: You must confirm material purity through process controls and verify final integrity with density and dielectric strength testing.

- If your primary focus is non-stick coatings: Specify controls on the raw dispersion's viscosity and mandate final checks on coating thickness and thermal cure protocols.

- If your primary focus is general-purpose machined parts: Standard checks for density and basic tensile properties are often sufficient to ensure material consistency.

Ultimately, a robust quality control strategy is what transforms a remarkable polymer into a reliable and predictable engineering solution.

Summary Table:

| QC Stage | Key Measures | Purpose |

|---|---|---|

| Raw Materials | Purity testing of precursors | Ensure successful polymerization and high molecular weight |

| Polymerization | Monitoring temperature & pressure | Control polymer chain length for strength and durability |

| Final Product | Density, tensile, thermal, and dimensional testing | Validate physical, mechanical, and thermal properties |

Need PTFE components with guaranteed quality and performance?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our rigorous quality control process, tailored to your application's demands, ensures every part delivers exceptional chemical resistance, thermal stability, and mechanical integrity.

Whether you require prototypes or high-volume production, we deliver material certainty. Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability