To properly specify a PTFE lip seal, you must focus on two critical areas beyond the seal itself: protecting the delicate seal lips from damage during installation and ensuring the shaft's hardness and surface roughness are optimized for the seal's unique dynamics. These precautions are essential for achieving the long-term, reliable performance PTFE seals are designed for.

The key to a successful PTFE lip seal application is recognizing that you are not just specifying a component, but designing an integrated sealing system. The seal, the shaft, and the housing must all be considered together to prevent premature failure.

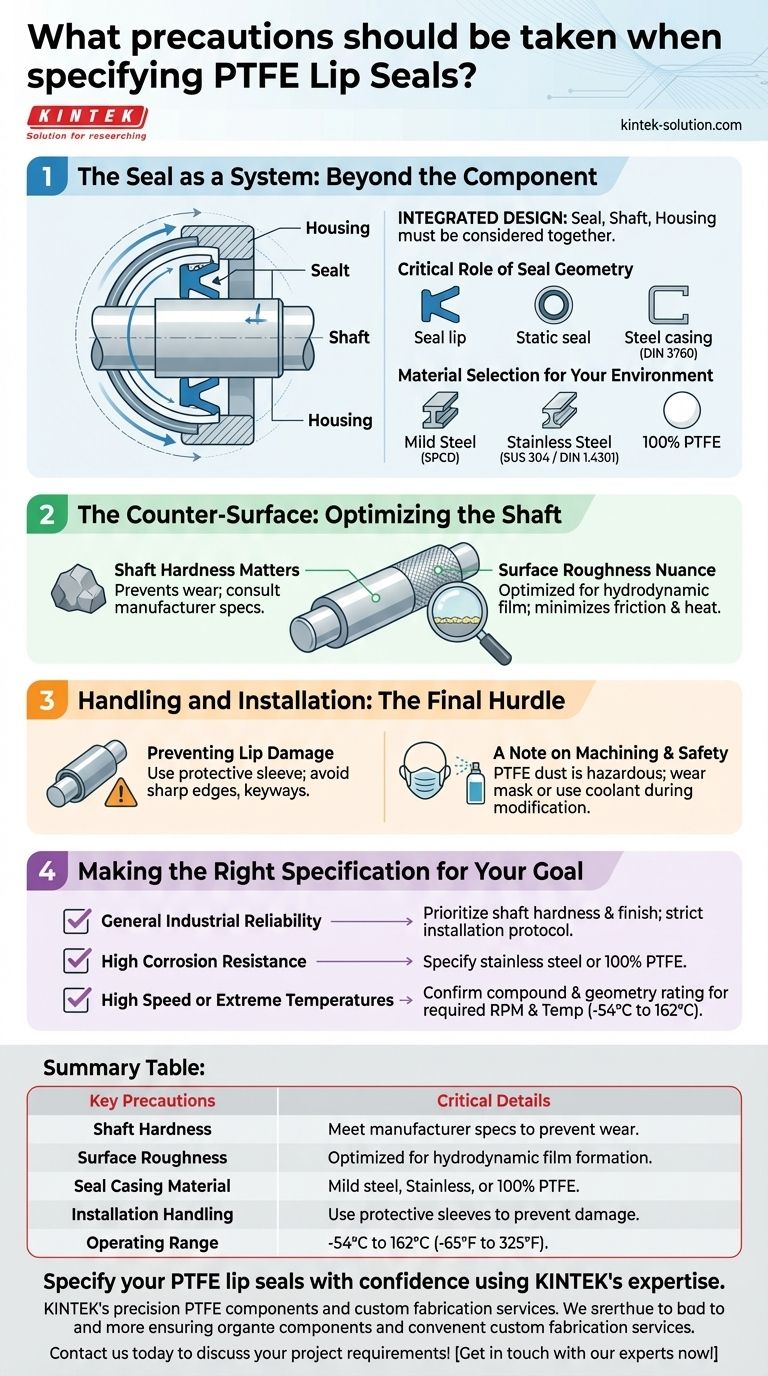

The Seal as a System: Beyond the Component

A PTFE lip seal's reliability is not accidental; it is the result of precise engineering across multiple elements. Viewing the seal as part of a larger system is the first step toward a successful specification.

The Critical Role of Seal Geometry

The foundation of a reliable seal is its physical design. This includes the specific geometry of the PTFE seal lip, the integrity of the static seal or gasket, and the precision of the steel casing.

This entire assembly is designed to meet strict interference standards, such as DIN 3760, which ensures a proper static seal is formed between the seal's outer casing and the equipment housing.

Material Selection for Your Environment

The environment dictates the materials. The standard seal casing is often a mild steel (SPCD), which is suitable for many industrial applications.

However, for environments with corrosive media or high humidity, specifying an upgraded casing like stainless steel (JIS SUS 304 or DIN 1.4301) is a crucial precaution. For the most extreme chemical applications, a 100% PTFE option without any steel casing is available.

The Counter-Surface: Optimizing the Shaft

Unlike traditional elastomeric seals, PTFE seals have a unique interaction with the shaft they run against. Failing to properly specify the shaft surface is one of the most common causes of leakage and premature wear.

Why Shaft Hardness Matters

The performance and lifespan of a PTFE seal are directly tied to the hardness of the shaft. A shaft that is too soft can be worn down by the seal material, especially if abrasive particles are present in the media.

Always consult the seal manufacturer's guidelines for the recommended shaft hardness range to ensure a durable, long-lasting sealing interface.

The Nuance of Surface Roughness

Proper shaft surface roughness is equally critical. The surface must be smooth enough to prevent abrading the PTFE lip, but not so polished that it inhibits the formation of a stable hydrodynamic film.

This microscopic film of lubricant is essential for minimizing friction and heat, which are key advantages of using PTFE seals in high-speed or high-pressure applications.

Handling and Installation: The Final Hurdle

Even a perfectly specified seal and shaft can fail if the installation process is flawed. The final precautions relate to handling and assembly.

Preventing Lip Damage

The sealing lip is the most critical and delicate part of the component. It can be easily nicked, scratched, or deformed by sharp edges, keyways, or threads during installation.

Using a protective plastic or cardboard insert over the shaft during assembly is a simple but vital precaution to shield the lip from any potential damage.

A Note on Machining and Safety

If any on-site modification of the PTFE material is necessary, take health precautions. Machining PTFE can produce fine micro dust that is hazardous if inhaled.

Always wear an appropriate mask or perform the work under a coolant to suppress dust and ensure operator safety.

Understanding the Trade-offs

While PTFE seals offer superior performance in demanding conditions, they require more careful system design than some alternatives.

Higher Initial Scrutiny

PTFE seals are less forgiving of sub-optimal shaft conditions than many elastomeric seals. They demand that you pay close attention to shaft hardness and finish during the design phase. They are not a universal "drop-in" replacement without this prior consideration.

Installation Sensitivity

The relative stiffness of PTFE material makes the seal lips more susceptible to damage during installation. Meticulous care and the use of installation sleeves are not just recommended; they are essential for reliability.

Making the Right Specification for Your Goal

Your final specification depends entirely on the demands of your application. Use these guidelines to make a sound decision.

- If your primary focus is general industrial reliability: Prioritize correct shaft hardness and surface finish and implement a strict, damage-free installation protocol.

- If your primary focus is high corrosion resistance: Specify stainless steel casings or, for the most aggressive media, a 100% PTFE seal without a metal case.

- If your primary focus is high speed or extreme temperatures: Confirm that the specific PTFE compound and seal geometry are rated for the required RPM and temperature range from -65°F to 325°F (-54°C to 162°C).

By treating the seal, shaft, and housing as a single engineered system, you ensure the exceptional performance and reliability your application demands.

Summary Table:

| Key Precautions | Critical Details |

|---|---|

| Shaft Hardness | Must meet manufacturer specs to prevent wear. |

| Surface Roughness | Optimized for hydrodynamic film formation. |

| Seal Casing Material | Choose from mild steel, stainless steel, or 100% PTFE based on environment. |

| Installation Handling | Use protective sleeves to prevent lip damage. |

| Operating Range | Standard PTFE: -54°C to 162°C (-65°F to 325°F). |

Specify your PTFE lip seals with confidence using KINTEK's expertise.

At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that a successful seal is part of an integrated system. Our team will help you navigate critical specifications like shaft hardness, surface finish, and material selection to ensure optimal performance and longevity for your application.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability. Contact us today to discuss your project requirements and let our solutions enhance your system's reliability.

Get in touch with our experts now!

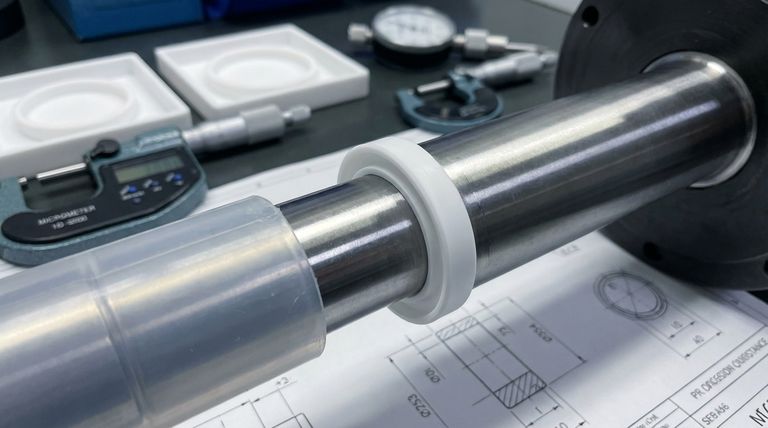

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do PTFE expansion bellows contribute to cost savings in power plants? Slash Maintenance and Downtime Costs

- What are PTFE envelope gaskets used for? Protect Delicate Flanges & Seal Aggressive Chemicals

- What are the key properties of fluoroplastics used in PTFE lined valves? Ensure Purity and Reliability

- In which industries are PTFE machined parts commonly used? Critical Components for Extreme Conditions

- What temperature range can PTFE encapsulated O-rings withstand? -60°C to 205°C, Depending on Core

- What are the self-lubricating properties of PTFE rod? Achieve Low-Friction, Maintenance-Free Performance

- What makes Teflon suitable for electrical applications? Unmatched Insulation for Extreme Conditions

- What temperature ranges can FEP and PTFE encapsulated O-rings withstand? A Guide to Extreme Environment Sealing