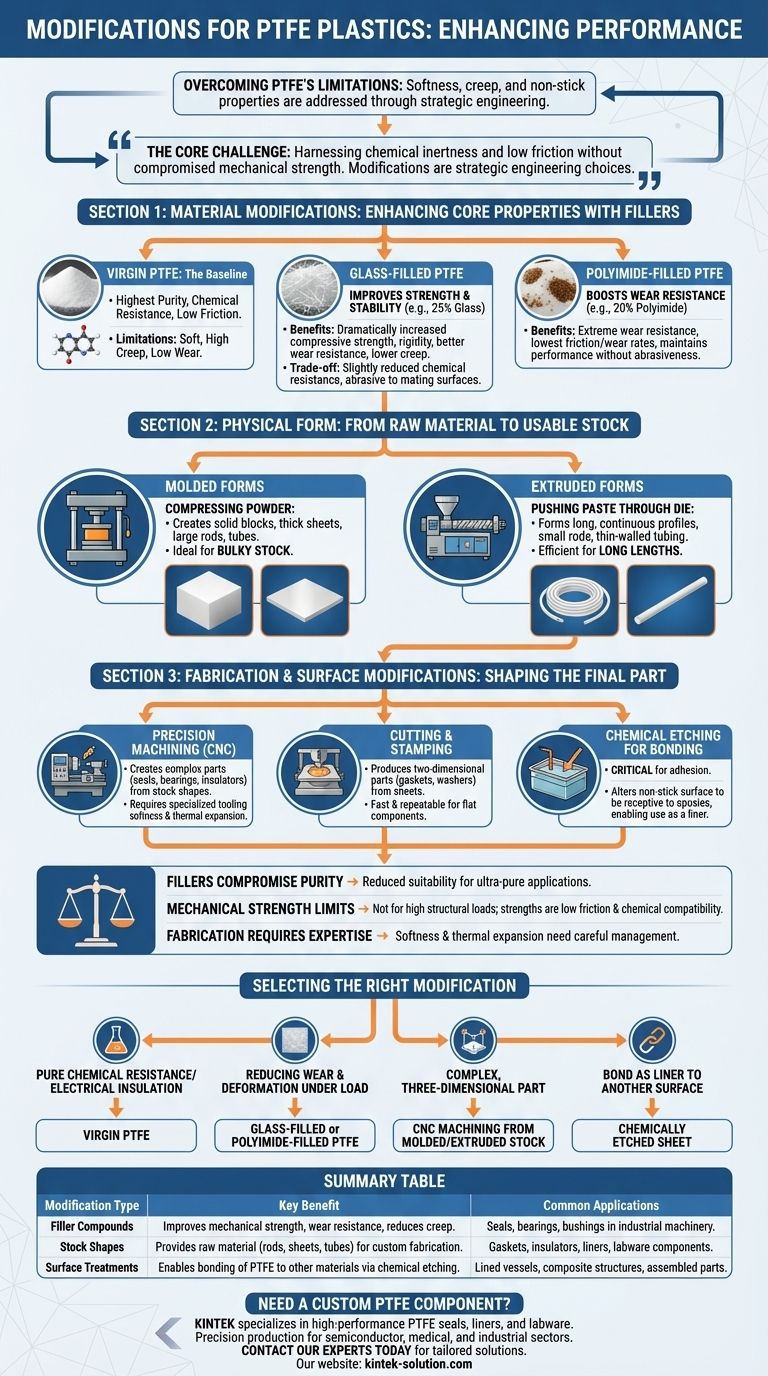

In essence, Polytetrafluoroethylene (PTFE) can be modified in three fundamental ways: by compounding it with fillers to enhance its mechanical properties, by forming it into various stock shapes like rods and sheets, and through fabrication processes like machining or etching to create finished parts. These modifications are designed to overcome the inherent limitations of pure PTFE, such as its softness and inability to be bonded.

The core challenge with PTFE is harnessing its exceptional chemical inertness and low friction without being constrained by its poor mechanical strength and non-stick surface. Modifications are not just variations; they are strategic engineering choices that tailor the material for specific, demanding applications.

Material Modifications: Enhancing Core Properties with Fillers

The most significant modifications to PTFE happen at the molecular level, where fillers are compounded with the virgin resin before it is formed. This is done to improve physical properties that pure PTFE lacks.

Virgin PTFE: The Baseline

Virgin, or unfilled, PTFE is the purest form of the material. It offers the highest chemical resistance, the lowest coefficient of friction, and excellent electrical insulation properties.

However, it is also very soft, exhibits significant "creep" or deformation under a constant load, and has relatively low wear resistance. It is best used where purity is paramount and mechanical demands are low.

Glass-Filled PTFE: Improving Strength and Stability

Adding microscopic glass fibers (a common blend is 25% glass) is one of the most popular modifications. This dramatically increases the compressive strength and rigidity of the material.

Glass-filled PTFE has much better wear resistance and lower creep than virgin PTFE. The trade-off is a slight reduction in chemical resistance and a more abrasive effect on mating surfaces.

Polyimide-Filled PTFE: Boosting Wear Resistance

For applications requiring extreme wear resistance, especially in dry, sliding-contact scenarios, polyimide is added as a filler. Blends like 20% or 40% polyimide are common.

This modification creates a high-performance composite with one of the lowest friction and wear rates among all PTFE blends. It maintains excellent performance without the abrasiveness of glass fillers.

Physical Form: From Raw Material to Usable Stock

PTFE is supplied in semi-finished stock shapes that serve as the starting point for final component fabrication. The manufacturing method—molding or extruding—determines the shape's size and characteristics.

Molded vs. Extruded Forms

Molding involves compressing PTFE powder in a mold to create solid blocks, thick sheets, large-diameter rods, and tubes. This method is ideal for producing large, bulky stock shapes.

Extrusion pushes PTFE paste through a die to form long, continuous profiles like small-diameter rods and thin-walled tubing. This is more efficient for producing long, uniform lengths.

Common Stock Shapes

Based on these processes, PTFE is readily available as skived sheets and films for gaskets, molded rods and plates for machining, and extruded tubes for fluid transfer or wire insulation. The sheer variety of available stock shapes is a primary form of modification for fabricators.

Fabrication and Surface Modifications: Shaping the Final Part

Once a material and stock shape are chosen, fabrication techniques create the final component. These processes are specialized to handle PTFE's unique properties.

Precision Machining (CNC)

PTFE is commonly machined using CNC lathes and mills to create complex, precise components like seals, bearings, insulators, and valve seats. Success requires specific tooling and techniques to manage the material's softness and high rate of thermal expansion.

Cutting and Stamping

For two-dimensional parts like gaskets and washers, PTFE sheets are processed using methods like die-cutting, stamping, or laser cutting. These provide a fast and repeatable way to produce flat components from sheet stock.

Chemical Etching for Bonding

Perhaps the most critical surface modification is chemical etching. Because PTFE is famously non-stick, adhesives cannot bond to its surface. Etching uses a chemical agent to alter the surface on one side, making it receptive to bonding with epoxies and other adhesives. This allows PTFE to be used as a low-friction liner on other structural materials.

Understanding the Trade-offs

Choosing a modification always involves balancing competing priorities. There is no single "best" version of PTFE.

Fillers Compromise Purity

Adding any filler, whether glass, polyimide, or carbon, compromises the absolute chemical purity and inertness of virgin PTFE. This can make filled grades unsuitable for certain ultra-pure, food-grade, or medical applications.

Mechanical Strength Still Has Limits

Even with fillers, PTFE is not a high-strength structural plastic. It should not be used in applications requiring high tensile or structural load-bearing capacity. Its strengths lie in low friction, temperature resistance, and chemical compatibility, not raw power.

Fabrication Requires Expertise

Machining PTFE is not like machining metal. Its softness can lead to part deflection, and its high thermal expansion can ruin tight tolerances if not properly managed with sharp tools, high speeds, and appropriate cooling.

Selecting the Right PTFE Modification

Your choice of modification should be driven directly by the primary demand of your application.

- If your primary focus is pure chemical resistance or electrical insulation: Specify virgin, unfilled PTFE for its unparalleled purity and dielectric strength.

- If your primary focus is reducing wear and deformation under load: Choose a glass-filled or polyimide-filled PTFE for significantly improved mechanical stability.

- If you need a complex, three-dimensional part: Plan to use CNC machining from a molded or extruded stock shape like a rod or block.

- If you need to bond PTFE as a liner to another surface: You must specify a chemically etched sheet to enable adhesion.

By understanding these modifications, you can transform PTFE from a simple material into a highly-engineered solution tailored to your specific challenge.

Summary Table:

| Modification Type | Key Benefit | Common Applications |

|---|---|---|

| Filler Compounds | Improves mechanical strength, wear resistance, and reduces creep. | Seals, bearings, bushings in industrial machinery. |

| Stock Shapes | Provides raw material (rods, sheets, tubes) for custom fabrication. | Gaskets, insulators, liners, labware components. |

| Surface Treatments | Enables bonding of PTFE to other materials via chemical etching. | Lined vessels, composite structures, assembled parts. |

Need a custom PTFE component that perfectly fits your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our precision production and custom fabrication expertise ensure you get a part that delivers superior chemical resistance, low friction, and reliability.

Contact our experts today to discuss your project requirements and discover how our tailored PTFE solutions can solve your specific challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE piston rings? Key Applications for Oil-Free & Corrosive Environments

- What precautions should be taken when installing PTFE O-rings? Avoid Permanent Damage and Seal Failure

- How are PTFE packings applied in the chemical industry? Ensure Leak-Free Sealing for Hazardous Fluids

- What are the primary applications of extra-thick PTFE washers (5mm – 6mm)? Critical for High-Pressure Sealing & Load-Bearing

- Where are thick PTFE washers (2mm – 4mm) typically used? For High-Pressure Sealing & Electrical Insulation

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What is the maximum working temperature for Teflon balls? Ensuring Safe and Reliable Performance

- What are the key properties of PTFE that make it suitable for bushes? Discover the Ultimate Self-Lubricating Solution