The primary method for welding PTFE sheets is to use a related fluoropolymer, most commonly PFA (Perfluoroalkoxy), as a welding rod in a specialized hot gas welding process. Because PTFE itself does not flow when melted, it cannot be directly fused to another piece of PTFE. The PFA acts as a melt-flowable intermediary that bonds the two non-flowing PTFE surfaces together.

The core challenge in joining PTFE is not its high melting point, but its extremely high melt viscosity—it turns into a gel, not a liquid. The solution is to use a chemically compatible fluoropolymer like PFA, which melts into a true, flowable liquid that can "wet" and fuse the PTFE sheets together.

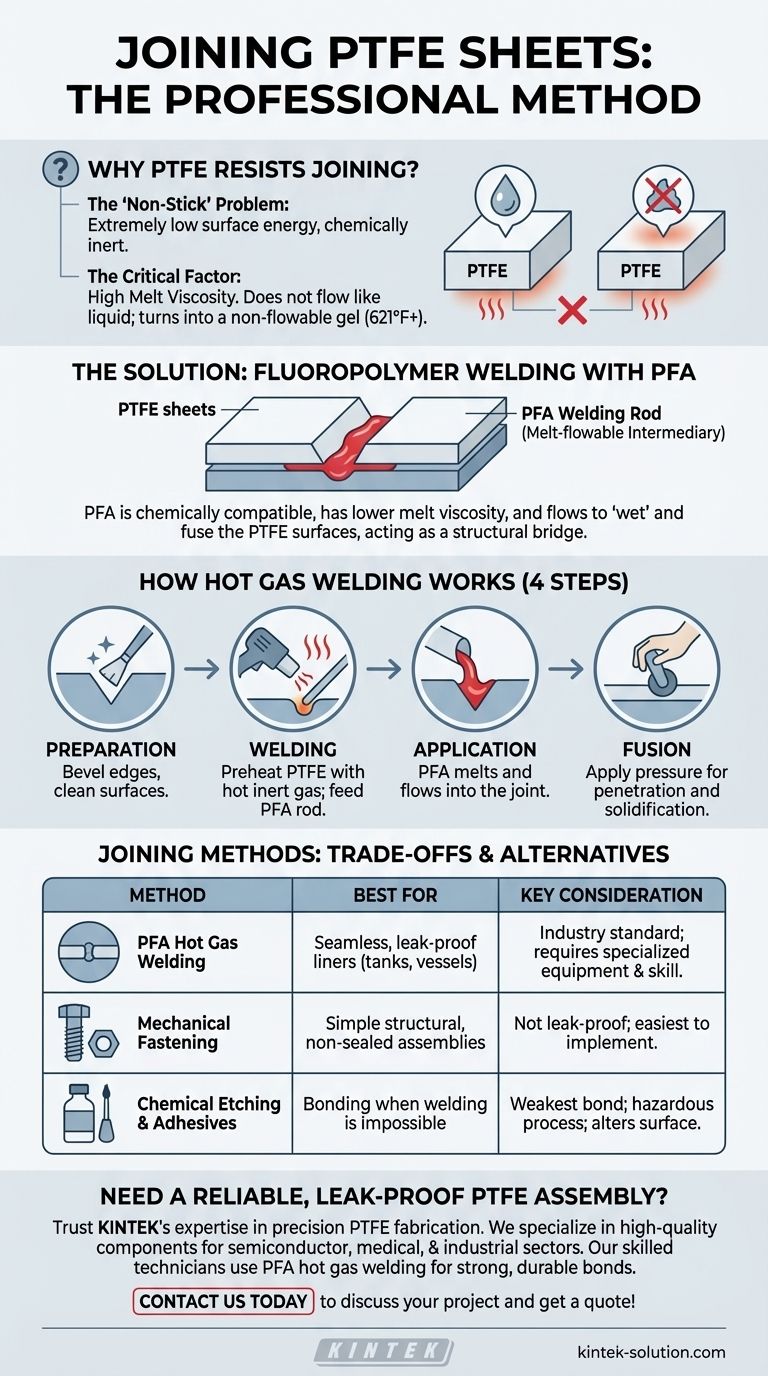

The Fundamental Challenge: Why PTFE Resists Joining

To understand the solution, you must first understand the unique properties that make PTFE so difficult to join with any method, whether welding or adhesives.

The "Non-Stick" Problem

PTFE is famously non-stick because it has extremely low surface energy and is chemically inert. This means that conventional adhesives have nothing to grab onto, causing them to peel away easily.

The Critical Factor: High Melt Viscosity

This is the most crucial concept. While PTFE does have a melting point of around 327°C (621°F), it does not behave like other thermoplastics.

When heated past this point, it does not become a liquid that can flow and mix. Instead, it transitions into a translucent, high-viscosity gel. This gel-like state prevents two heated PTFE surfaces from flowing into one another to create a homogenous weld.

The Professional Solution: Fluoropolymer Welding

Because you cannot melt-fuse PTFE to itself, the industry standard is to introduce a different, melt-processable fluoropolymer that can act as a bridge.

The Role of PFA as a Welding Rod

PFA is the material of choice for this process. It is chemically very similar to PTFE, ensuring excellent chemical resistance and a strong bond.

Crucially, PFA has a much lower melt viscosity. When heated, it flows like a true viscous liquid. This allows it to be applied to the joint, where it can wet the surfaces of the two PTFE sheets.

Think of the PFA as a specialized "hot-melt glue" or, more accurately, a welding rod that is chemically compatible with the base material.

How the Hot Gas Welding Process Works

This is a specialized fabrication technique that requires precision and expertise.

- Preparation: The edges of the PTFE sheets are beveled to create a "V" groove, increasing the surface area for the weld. The surfaces must be impeccably clean.

- Welding: A specialized hot gas welding gun directs a stream of superheated inert gas (like nitrogen) into the joint. This preheats the PTFE surfaces.

- Application: A PFA welding rod is fed into the hot gas stream, causing it to melt and flow into the prepared groove between the PTFE sheets.

- Fusion: The welder uses steady pressure and motion to ensure the molten PFA fully penetrates the joint and fuses with the hot, gel-like surfaces of the PTFE. Upon cooling, the PFA solidifies, creating a strong, permanent weld.

Understanding the Trade-offs and Alternatives

While PFA welding is the most robust method, it's important to be aware of its limitations and other potential, though less common, approaches.

Limitations of PFA Welding

The primary trade-off is that this is not a simple, on-site task. It demands skilled technicians and specialized equipment to precisely control temperature and technique. The resulting seam, while strong, is made of PFA, which has slightly different (though very similar) thermal and mechanical properties than the parent PTFE.

Chemical Etching and Adhesives

For applications where welding is not feasible, PTFE can be chemically bonded. This process involves using a hazardous etchant, typically a sodium-naphthalene solution, to strip fluorine atoms from the PTFE surface.

This creates a carbonaceous, brown-colored layer that is mechanically receptive to adhesives like epoxies. This method is dangerous, requires extreme care, and typically results in a weaker bond than a proper PFA weld.

Mechanical Fastening

The simplest method is to join sheets with mechanical fasteners, such as fluoropolymer bolts or rivets. This does not create a seamless, leak-proof joint and is only suitable for applications where a continuous, sealed surface is not the primary objective.

Making the Right Choice for Your Application

Selecting the correct joining method depends entirely on your project's technical requirements.

- If your primary focus is a seamless, leak-proof, and chemically resistant liner (e.g., for a tank): PFA hot gas welding is the only reliable, industry-standard method. You must engage a specialized fluoropolymer fabricator.

- If your primary focus is a simple mechanical connection without a perfect seal: Use mechanical fasteners. This is a straightforward approach for structural, non-sealed assemblies.

- If your primary focus is bonding and welding is impossible: Chemical etching followed by a purpose-built adhesive is a niche alternative, but it compromises the PTFE's surface properties and requires handling of hazardous materials.

Ultimately, joining PTFE successfully requires acknowledging its unique material science and employing a method designed to overcome its inherent resistance to fusion.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| PFA Hot Gas Welding | Seamless, leak-proof liners (tanks, vessels) | Industry standard; requires specialized equipment & skill |

| Mechanical Fastening | Simple structural, non-sealed assemblies | Not leak-proof; easiest to implement |

| Chemical Etching & Adhesives | Bonding when welding is impossible | Weakest bond; hazardous process; alters surface |

Need a reliable, leak-proof PTFE assembly? Trust KINTEK's expertise in precision PTFE fabrication. We specialize in manufacturing high-quality PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. Our skilled technicians use specialized PFA hot gas welding to create strong, durable bonds tailored to your application's requirements, from prototypes to high-volume orders. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- How are rocker bearings integrated with PTFE sliding arrangements? Achieve Complex Multi-Directional Movement

- What are the limitations of PTFE sheet lining in chemical tanks? Understand the Critical Trade-Offs

- How do PTFE bellow seals perform at low temperatures? Ensuring Reliability in Cryogenic Applications

- What are the advantages of carbon and MoS2-filled PTFE? Enhance Strength, Wear, and Performance

- What are some common applications for PTFE rotary seals? Sealing Solutions for Extreme Environments

- Why are PTFE rotary seals becoming a preferred choice for engineers and OEMs? Solve Critical Performance Failures

- Can Teflon bearings be customized for specific applications? Tailor PTFE Bearings for Your Unique Needs