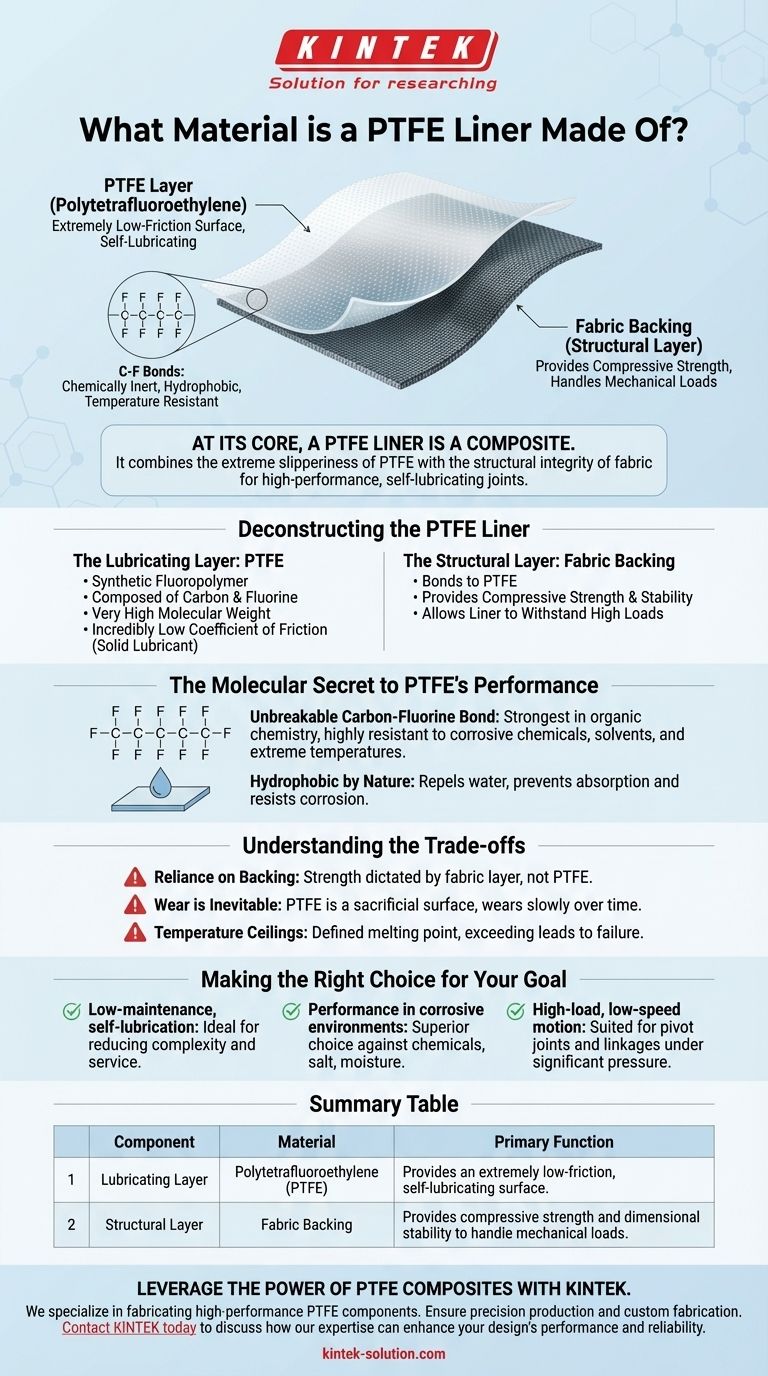

At its core, a PTFE liner is not a single material but a composite. It is made of two distinct components: a layer of Polytetrafluoroethylene (PTFE) bonded to a structural fabric backing. The PTFE provides an extremely low-friction surface, while the fabric provides the compressive strength needed to handle mechanical loads.

The critical insight is that PTFE liners combine the extreme slipperiness of a fluoropolymer with the structural integrity of a fabric. This creates a high-performance, self-lubricating surface that would otherwise be too soft to use in mechanical applications.

Deconstructing the PTFE Liner

To understand how a PTFE liner functions, you must look at its two primary components and the roles they play. Each is chosen for a specific set of properties that, when combined, create a unique solution for high-load, low-friction joints.

The Lubricating Layer: PTFE

The functional surface of the liner is made from Polytetrafluoroethylene (PTFE). This is a synthetic fluoropolymer, a type of plastic in the same family as Teflon.

PTFE is composed exclusively of carbon and fluorine atoms. These atoms form a long, linear chain structure with a very high molecular weight.

This unique chemical makeup gives PTFE its most important characteristic: an incredibly low coefficient of friction. It acts as a solid lubricant, eliminating the need for grease or oil.

The Structural Layer: Fabric Backing

On its own, PTFE is a relatively soft material that would deform or extrude under significant pressure.

To counteract this, the PTFE is bonded to a strong fabric backing. This backing provides the necessary compressive strength and dimensional stability.

This composite structure allows the liner to withstand high loads while maintaining the low-friction properties of the PTFE surface.

The Molecular Secret to PTFE's Performance

The exceptional properties of PTFE are not accidental; they are a direct result of its atomic structure. Understanding this structure reveals why it's so effective in demanding environments.

The Unbreakable Carbon-Fluorine Bond

The bond between carbon and fluorine atoms is one of the strongest in organic chemistry.

This powerful bond makes PTFE chemically inert. It is highly resistant to corrosive chemicals, solvents, and environmental degradation.

This same atomic stability also gives PTFE its high resistance to extreme temperatures, allowing it to function where other lubricants would fail.

Hydrophobic by Nature

PTFE is hydrophobic, meaning it repels water.

This property is crucial in applications exposed to moisture, as it prevents water absorption and helps resist corrosion within the mechanical joint.

Understanding the Trade-offs

While highly effective, PTFE liners are not a universal solution. Their composite nature introduces specific limitations that must be considered in any engineering design.

Reliance on the Backing Material

The ultimate strength of the liner is dictated by its fabric backing, not the PTFE. The liner can only handle as much load as its structural layer can support.

Wear is Inevitable

The PTFE layer is a sacrificial surface. While durable, it is designed to wear away slowly over thousands of cycles. It is a consumable component with a finite operational lifespan.

Temperature Ceilings

Although resistant to high temperatures, PTFE has a defined melting point. Exceeding its operational temperature range can lead to material degradation and catastrophic failure of the bearing surface.

Making the Right Choice for Your Goal

Selecting a PTFE liner is about matching its unique profile to the demands of your application.

- If your primary focus is low-maintenance and self-lubrication: A PTFE liner is ideal, as it eliminates the need for any external grease or oil, reducing complexity and service requirements.

- If your primary focus is performance in corrosive environments: The chemical inertness of PTFE makes it a superior choice for applications exposed to harsh chemicals, salt, or moisture.

- If your primary focus is high-load, low-speed motion: The composite structure is perfectly suited for pivot joints and linkages that experience significant pressure but do not rotate at high speeds.

By understanding this material as a two-part system, you can effectively leverage its powerful self-lubricating and resilient properties in your designs.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Lubricating Layer | Polytetrafluoroethylene (PTFE) | Provides an extremely low-friction, self-lubricating surface. |

| Structural Layer | Fabric Backing | Provides compressive strength and dimensional stability to handle mechanical loads. |

Leverage the power of PTFE composites in your application.

PTFE liners are engineered solutions, and their performance depends on precise manufacturing. At KINTEK, we specialize in fabricating high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE expertise can enhance your design's performance and reliability.

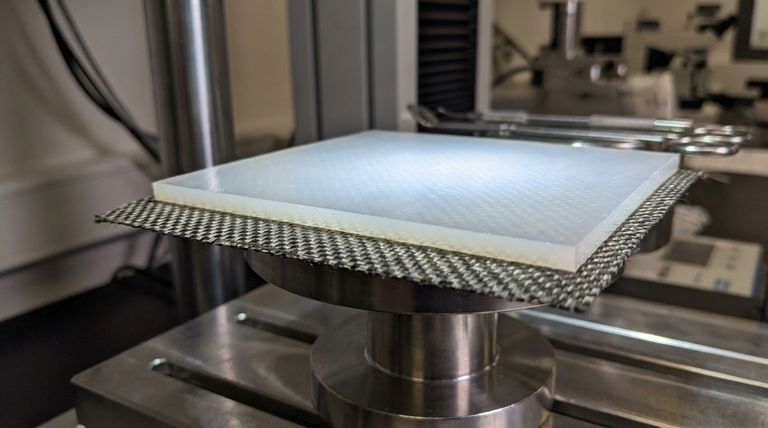

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry