At their core, PTFE vials are exceptionally effective at preventing contamination and evaporation due to the material's inherent chemical inertness and its ability to form a precise, physically tight seal. Unlike other materials, Polytetrafluoroethylene (PTFE) does not react with or leach into the sample, while its machined construction allows for a closure system that creates a truly airtight and leak-proof barrier.

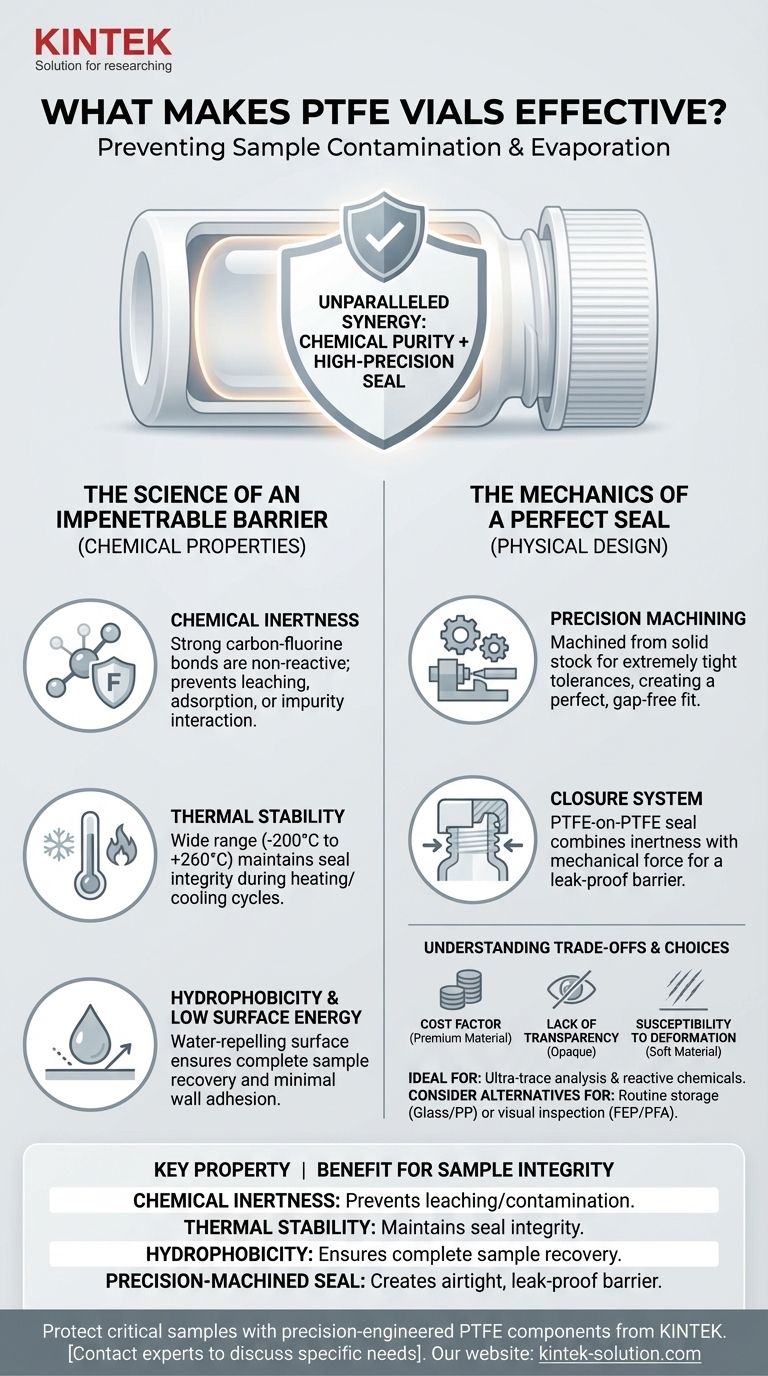

The true value of a PTFE vial isn't just the material itself, but the synergy between its unparalleled chemical purity and the high-precision seal it forms with its closure. This combination provides the ultimate defense for ensuring sample integrity.

The Science of an Impenetrable Barrier

To understand why PTFE is the material of choice for the most sensitive applications, we must look at both its chemical properties and the physical design of the vials themselves. These two factors work in concert to protect your sample.

Chemical Inertness: The Foundation of Purity

PTFE is one of the most chemically resistant polymers known. Its molecular structure consists of a carbon backbone completely shielded by fluorine atoms.

This strong carbon-fluorine bond is extremely stable and non-reactive. As a result, the vial walls will not interact with, adsorb, or leach impurities into your sample, which is a common risk with glass or lower-grade plastics.

Thermal Stability: A Seal That Lasts

The integrity of a seal can be compromised by temperature fluctuations, which cause materials to expand or contract. PTFE has an exceptionally wide operating temperature range (typically -200°C to +260°C).

This stability means the vial and its closure maintain their dimensional integrity, ensuring the seal remains tight even during heating, cooling, or autoclaving cycles.

Hydrophobicity: Ensuring Complete Sample Recovery

PTFE is highly hydrophobic (water-repelling) and has very low surface energy. This means that aqueous and even many organic liquids do not "wet" or stick to the surface.

This property is critical for preventing sample loss. When you transfer the contents, you can be confident that a minimal amount of the sample is left clinging to the vial walls, which is essential for quantitative analysis.

The Mechanics of a Perfect Seal

A superior material is only half the solution. The physical engineering of the vial and its cap is what creates the airtight environment.

The Role of Precision Machining

Many high-quality PTFE vials are not mass-produced by molding but are machined from solid PTFE stock. This manufacturing process allows for extremely tight tolerances.

The threads on the vial and cap are cut with high precision, ensuring a perfect fit that eliminates gaps. The sealing surfaces are also machined to be perfectly flat, creating maximum contact area for the seal.

The Closure System Is Critical

A vial is only as good as its cap. The closure on a PTFE vial is specifically designed to work with the vial body to create a leak-proof system.

The cap itself is often made of PTFE, or it contains a PTFE liner. When tightened, this creates a PTFE-on-PTFE seal that combines the material's inertness with the mechanical force needed to prevent any gas or liquid exchange with the outside environment.

Understanding the Trade-offs

While PTFE offers superior performance, it's important to be objective about its limitations. It is not the right choice for every single application.

The Cost Factor

PTFE is a premium material, and the precision machining process adds to the cost. These vials are significantly more expensive than their glass, polypropylene, or polyethylene counterparts. Their use is typically justified for irreplaceable samples or ultra-trace analysis where purity is paramount.

Lack of Transparency

PTFE is opaque. You cannot visually inspect your sample without opening the vial, which can be a drawback if you need to monitor for color changes, precipitation, or phase separation.

Susceptibility to Deformation

While chemically robust, PTFE is a relatively soft material. It can be scratched or gouged by sharp tools. A deep scratch on a sealing surface could potentially compromise the integrity of the seal, requiring careful handling.

Making the Right Choice for Your Goal

Selecting the correct vial requires matching the material properties to your analytical needs and budget.

- If your primary focus is ultra-trace metal analysis or storing highly reactive chemicals: PTFE is the gold standard, as its extreme inertness prevents sample contamination from leaching.

- If your primary focus is routine storage of stable, non-reactive compounds: A more economical choice like borosilicate glass or high-quality polypropylene may be perfectly adequate.

- If your primary focus is an application requiring frequent visual inspection: A transparent material like glass, FEP, or PFA is a more practical choice than opaque PTFE.

By understanding these fundamental material properties and design considerations, you can confidently select the containment solution that best protects the integrity of your most critical samples.

Summary Table:

| Key Property | Benefit for Sample Integrity |

|---|---|

| Chemical Inertness | Prevents leaching & contamination; ideal for ultra-trace analysis. |

| Thermal Stability (-200°C to +260°C) | Maintains seal integrity during heating, cooling, or autoclaving. |

| Hydrophobicity & Low Surface Energy | Ensures complete sample recovery with minimal wall adhesion. |

| Precision-Machined Seal | Creates an airtight, leak-proof barrier for maximum protection. |

Protect your most critical samples with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE vials, seals, liners, and labware are machined to the highest tolerances to guarantee sample purity and prevent evaporation. We specialize in transforming your unique requirements—from prototypes to high-volume orders—into reliable, contamination-free solutions.

Contact our experts today to discuss your specific needs and receive a tailored quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of the PTFE bottle's non-stick surface? Ensure Purity and Efficiency in Your Lab

- What are the benefits of silicone/PTFE liners? Ensure Unmatched Sample Purity and Integrity

- What factors should be considered when selecting a PTFE shovel for laboratory use? Ensure Chemical Inertness & Sample Integrity

- What material is used to mold PTFE labware? The Critical Role of Pure PTFE Resin

- In what ways are PTFE silicone septas versatile for pharmaceutical applications? Ensuring Sample Integrity from Discovery to QC

- What is the advantage of using PTFE ferromagnetic support discs? Achieve Flawless, Efficient Sample Preparation

- How do the costs of PTFE and silicone septa compare? Understand the Value Beyond Price

- What are the benefits of PTFE stirrers? Ensure Chemical Purity and Protect Your Labware