At its core, Polytetrafluoroethylene (PTFE) is suitable for medical applications due to an exceptional combination of three properties: it is highly biocompatible, chemically inert, and has an extremely low-friction surface. This unique trifecta means it can safely exist within the human body without causing adverse reactions, resist degradation from bodily fluids or harsh sterilization processes, and allow devices to move smoothly while minimizing tissue damage and bacterial adhesion.

The fundamental reason PTFE is a cornerstone material in medicine is its ability to perform its function without interfering with the body's complex biological systems. It solves the critical challenge of creating devices that are both effective and safe for direct, often long-term, human contact.

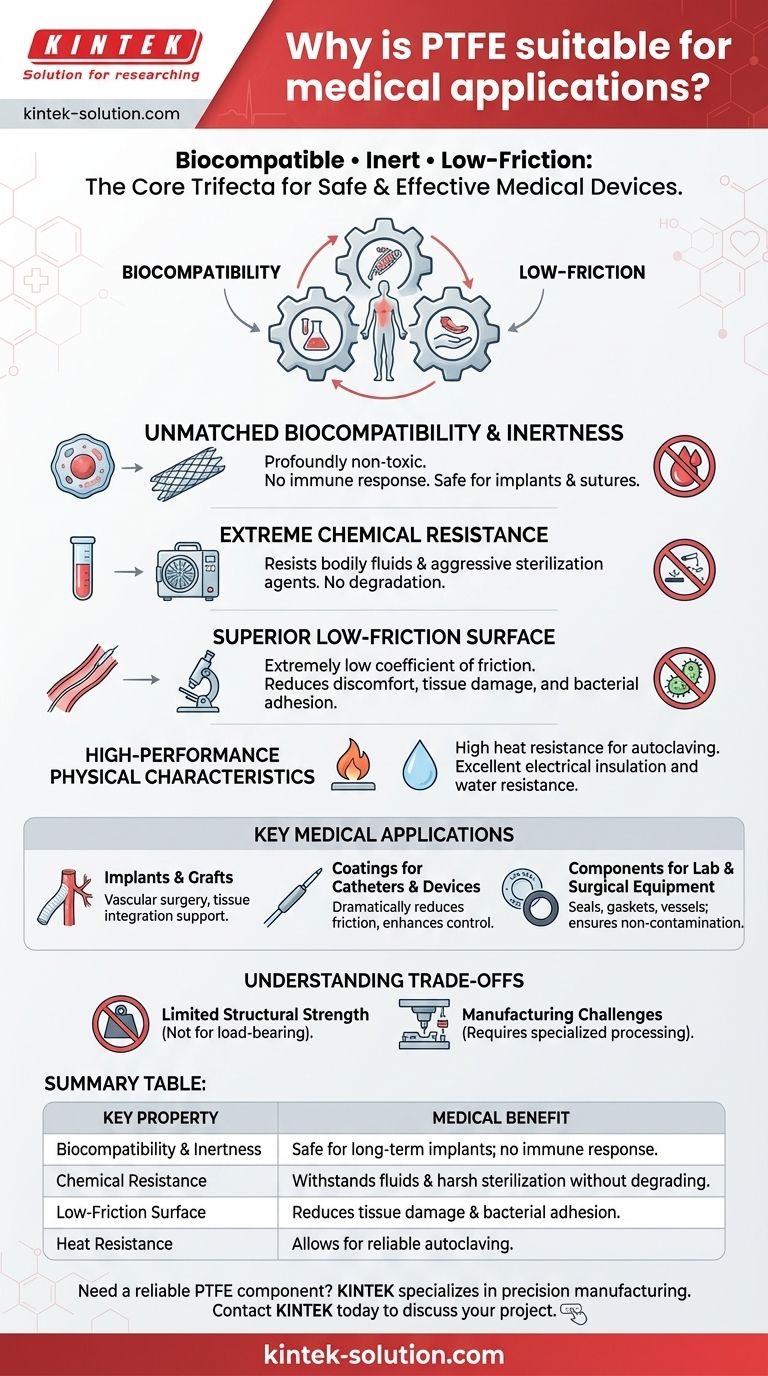

The Core Properties Driving Medical Adoption

To understand why PTFE is so prevalent, we must analyze the specific characteristics that make it uniquely qualified for sensitive medical environments. These properties work in concert to ensure both patient safety and device reliability.

Unmatched Biocompatibility and Inertness

The most critical requirement for any material used inside the body is biocompatibility. PTFE is profoundly non-toxic and biologically inert.

This means it does not trigger an immune response, cause inflammation, or release harmful substances when it comes into contact with living tissue or bodily fluids. This inert nature is paramount for implants, sutures, and internal devices.

Extreme Chemical Resistance

The human body is a chemically active environment, and medical devices must also withstand aggressive sterilization agents.

PTFE is resistant to virtually all chemicals, acids, and bases. This ensures that a component will not degrade over time, maintaining its structural integrity and preventing the leaching of potentially harmful byproducts into the patient.

Superior Low-Friction, Non-Adhesive Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is vital.

For devices like catheters, this property reduces the discomfort and potential for tissue damage during insertion and removal. Critically, this non-adhesive surface also makes it difficult for bacteria to attach, helping to reduce the risk of hospital-acquired infections.

High-Performance Physical Characteristics

Beyond its core biological and chemical properties, PTFE offers other advantages for device engineering.

It is highly resistant to heat, which allows it to be easily sterilized using methods like autoclaving. It also possesses excellent water resistance and electrical insulation, making it a versatile component in complex medical machinery.

Key Medical Applications of PTFE

These properties translate directly into a wide range of life-saving applications, from simple components to complex implants.

Implants and Grafts

Because it is so well-tolerated by the body, PTFE is frequently used as a graft material in vascular surgery. Its porous structure can be engineered to support and encourage the growth of new cells, aiding in tissue integration for things like ligament replacements.

Coatings for Catheters and Devices

PTFE's most common application is as a coating. Applying an ultra-thin layer of PTFE to catheters, guide wires, and surgical instruments dramatically reduces friction. This not only improves patient comfort but also enhances the physician's control and reduces the risk of complications.

Components for Lab and Surgical Equipment

The chemical inertness of PTFE makes it an ideal material for seals, gaskets, and vessels used in laboratory and surgical settings. It ensures that samples are not contaminated and that equipment can withstand repeated cleaning and sterilization cycles without degrading, guaranteeing reliability.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. While PTFE's properties are exceptional, there are important trade-offs to consider in device design.

Limited Structural Strength

PTFE is a relatively soft material. It is not suitable for load-bearing applications like major joint replacements on its own. Its strength lies in its surface properties and inertness, which is why it is more often used as a coating, liner, or component rather than a primary structural element.

Manufacturing and Processing Challenges

Compared to more common polymers, PTFE can be difficult to process. It does not melt and flow like other thermoplastics, requiring specialized manufacturing techniques such as sintering or machining from solid stock. This can increase the cost and complexity of producing PTFE components.

Making the Right Choice for Your Goal

Selecting a material requires aligning its properties with your primary objective. When considering PTFE, your focus will determine its value.

- If your primary focus is patient safety and biocompatibility: PTFE is a premier choice for any application involving direct contact with internal tissues, ensuring a minimal biological reaction.

- If your primary focus is device performance and smooth operation: The unparalleled low-friction surface of PTFE makes it ideal for catheters, guide wires, and any component that must move without damaging sensitive tissues.

- If your primary focus is long-term reliability and chemical durability: PTFE's resistance to chemical attack and high temperatures makes it the right material for reusable components that must endure aggressive sterilization.

Ultimately, PTFE's value in medicine comes from its unique ability to solve problems without creating new ones, making it an indispensable tool for modern healthcare.

Summary Table:

| Key Property | Medical Benefit |

|---|---|

| Biocompatibility & Inertness | Safe for long-term implants; does not trigger immune response. |

| Chemical Resistance | Withstands bodily fluids and harsh sterilization without degrading. |

| Low-Friction Surface | Reduces tissue damage and bacterial adhesion in catheters and devices. |

| Heat Resistance | Allows for reliable autoclaving and sterilization. |

Need a reliable PTFE component for your medical device?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, coatings, and custom labware. Our components are trusted in the medical, semiconductor, and laboratory industries for their critical role in ensuring patient safety and device performance.

We offer custom fabrication from prototypes to high-volume orders, ensuring your product meets the highest standards of biocompatibility and reliability.

Contact KINTEK today to discuss your project requirements and leverage our expertise in high-performance polymer solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What precautions should be taken when using Teflon cookware? Essential Safety Tips for Non-Stick Pans

- What is the difference between virgin PTFE and filled PTFE? Choose the Right Material for Your Application

- Why is PTFE considered an ideal substitute for other plastics in high-temperature applications? Superior Thermal Stability & Performance

- What are some alternatives to PTFE and how do they compare? A Guide to Fluoropolymer Selection

- What is the sintering process for PTFE billets? A Guide to Achieving Material Integrity

- What are the characteristics of PFA Teflon? | Extreme Performance Meets Design Freedom

- What are the key properties of Teflon (PTFE)? Unlocking Extreme Performance for Demanding Applications

- What are the physical properties of PTFE? Unlocking Its High-Performance Capabilities