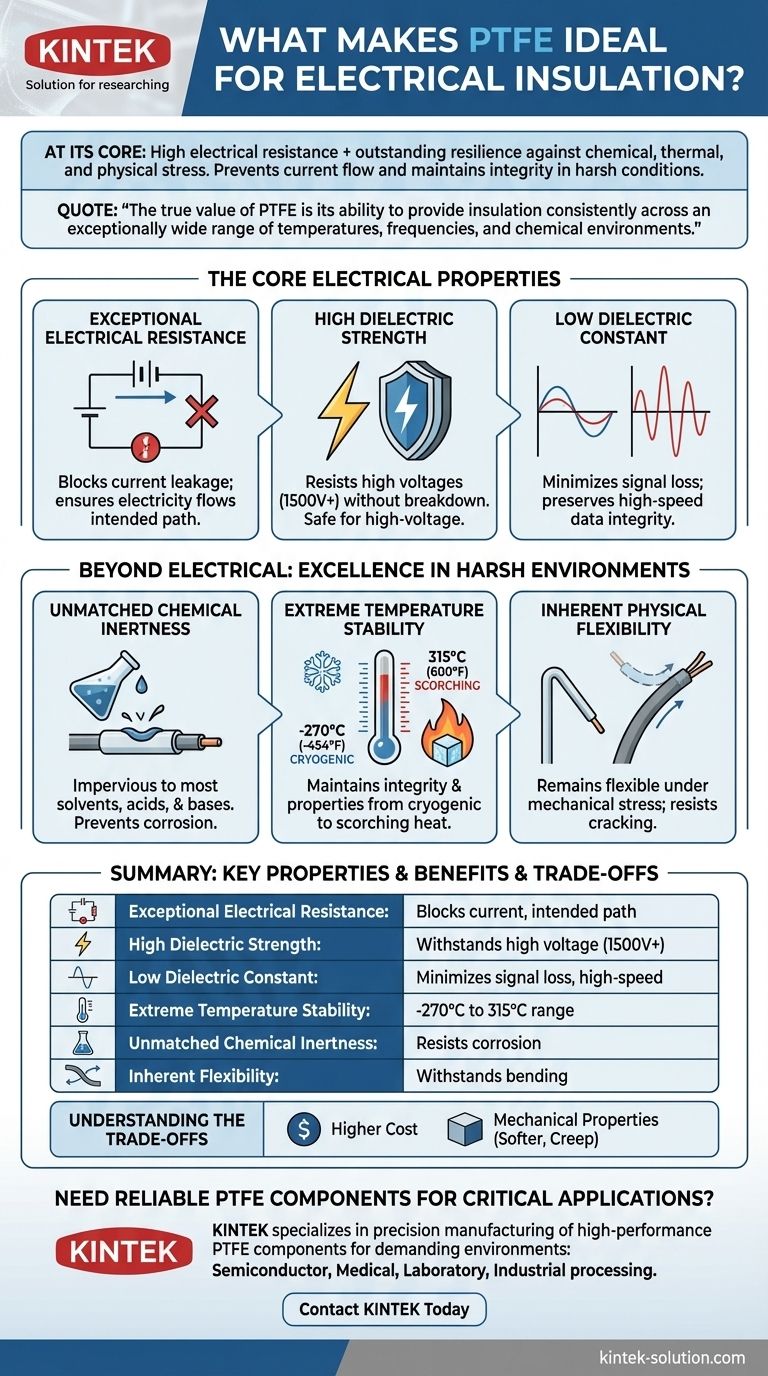

At its core, Polytetrafluoroethylene (PTFE) is an ideal electrical insulator because it combines extremely high electrical resistance with outstanding resilience against chemical, thermal, and physical stress. This unique fusion of properties ensures that it not only prevents the flow of electricity but also maintains its integrity in the harshest operating conditions, protecting critical electronic components reliably over time.

The true value of PTFE isn't just its excellent electrical insulation, but its ability to provide that insulation consistently across an exceptionally wide range of temperatures, frequencies, and chemical environments where lesser materials would quickly fail.

The Core Electrical Properties of PTFE

The primary function of an insulator is to resist the flow of electrical current. PTFE accomplishes this with exceptional proficiency due to a few key electrical characteristics.

Exceptional Electrical Resistance

The most fundamental property of an insulator is its ability to block current. PTFE has a very high electrical resistance, effectively stopping current leakage and ensuring electricity flows only along its intended path.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand high voltage without breaking down. PTFE can resist high voltages (up to 1500 volts or more depending on thickness), making it a safe and reliable choice for wires, cables, and connectors in high-voltage applications.

Low Dielectric Constant

For high-frequency electronics, such as in advanced transformers or communication cables, the dielectric constant is critical. PTFE has a very low dielectric constant, meaning it stores very little electrical energy. This minimizes signal loss and preserves the integrity of high-speed data transmission.

Beyond Electrical: Why PTFE Excels in Harsh Environments

While its electrical properties are top-tier, PTFE's dominance as an insulator is secured by its extraordinary physical durability. Electrical components rarely operate in perfect conditions, and PTFE is built for the real world.

Unmatched Chemical Inertness

PTFE is virtually impervious to almost all common solvents, acids, and bases. This means the insulation will not corrode or degrade when exposed to chemicals, ensuring long-lasting protection for the underlying conductor.

Extreme Temperature Stability

PTFE maintains its integrity and insulating properties across an incredible temperature range, from a cryogenic -454°F (-270°C) to a scorching 600°F (315°C). It won't become brittle in the cold or melt in high-heat processes, providing consistent performance where other plastics would fail.

Inherent Physical Flexibility

The strong carbon-fluorine bonds in PTFE's molecular structure allow it to remain flexible even when subjected to mechanical stress. This makes it ideal for applications like wiring and cabling that require bending and movement without cracking the insulation.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE is a superior insulator, its unique properties come with practical considerations.

Cost Considerations

PTFE is generally more expensive than common insulators like PVC or polyethylene. For standard, low-demand applications, a less robust material may be more cost-effective. Specialized or high-performance grades of PTFE further increase this cost.

Mechanical Properties

While flexible, PTFE is a relatively soft material. It can be susceptible to "creep" or cold flow under high, sustained mechanical loads. In high-abrasion environments, it may require reinforcement or a protective jacket to prevent physical damage.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on the demands of the operating environment and the required level of reliability.

- If your primary focus is high-frequency signal integrity: PTFE's low dielectric constant makes it the industry standard for coaxial cables, PCBs, and high-speed connectors.

- If your primary focus is reliability in extreme environments: Its unparalleled chemical and thermal stability ensures the insulation will not fail due to corrosive agents or temperature swings.

- If your primary focus is high-voltage protection: Its high dielectric strength provides a robust and reliable barrier against electrical breakdown and current leakage in demanding applications.

Ultimately, PTFE's unique combination of elite electrical performance and physical resilience makes it the definitive choice for insulation where failure is not an option.

Summary Table:

| Key Property | Benefit for Electrical Insulation |

|---|---|

| Exceptional Electrical Resistance | Effectively blocks current leakage, ensuring electricity flows only where intended. |

| High Dielectric Strength | Withstands high voltages (up to 1500V+) without breaking down. |

| Low Dielectric Constant | Minimizes signal loss, ideal for high-frequency electronics and data transmission. |

| Extreme Temperature Stability | Maintains integrity and performance from -270°C to 315°C. |

| Unmatched Chemical Inertness | Resists corrosion from solvents, acids, and bases for long-lasting protection. |

| Inherent Flexibility | Withstands bending and movement without cracking, perfect for wiring and cables. |

Need Reliable PTFE Components for Your Critical Applications?

When failure is not an option, you need an insulation material that won't let you down. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, labware, and custom insulators—for the most demanding environments.

We serve industries where reliability is paramount:

- Semiconductor manufacturing

- Medical and life sciences equipment

- Laboratory and analytical instrumentation

- Industrial processing and high-voltage systems

Whether you require prototypes or high-volume production, our custom fabrication expertise ensures you get the exact PTFE solution your application demands.

Contact KINTEK today to discuss your project and discover how our PTFE components can protect your critical electronics.

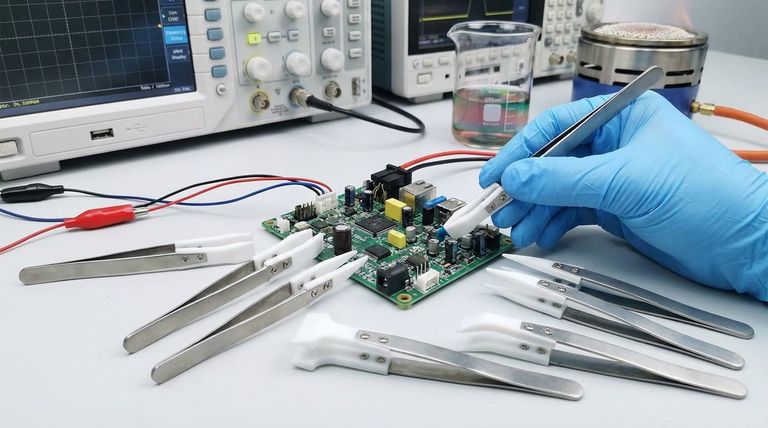

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE resistant to corrosion? Discover the Secret to Unmatched Chemical Inertness

- What automotive application benefits from PTFE coating? Enhance Vehicle Reliability and Performance

- What is PTFE and what are its primary properties? Discover the Ultimate High-Performance Polymer

- Why is PTFE highly regarded in the industry? Unmatched Chemical & Thermal Resistance

- What environmental factors is PTFE resistant to, contributing to its durability? Discover Its Unmatched Resistance

- What are the advantages of PTFE over Polyethylene Terephthalate (PET)? Key Benefits for Demanding Applications

- What are some consumer product applications of PTFE? Discover its Versatility Beyond Non-Stick Pans

- What is the chemical composition of Teflon? The Science Behind Its Non-Stick Properties