In essence, PTFE guide strips are a reliable choice for harsh environments because of their fundamental material properties. They possess an exceptional combination of chemical inertness, thermal stability across a wide temperature range, and superior mechanical performance characterized by low friction and high wear resistance.

The reliability of PTFE guide strips in harsh environments stems not from a single attribute, but from a powerful synergy of properties. They don't just survive chemical exposure and extreme temperatures; they maintain superior mechanical performance, ensuring operational stability and longevity where other materials would fail.

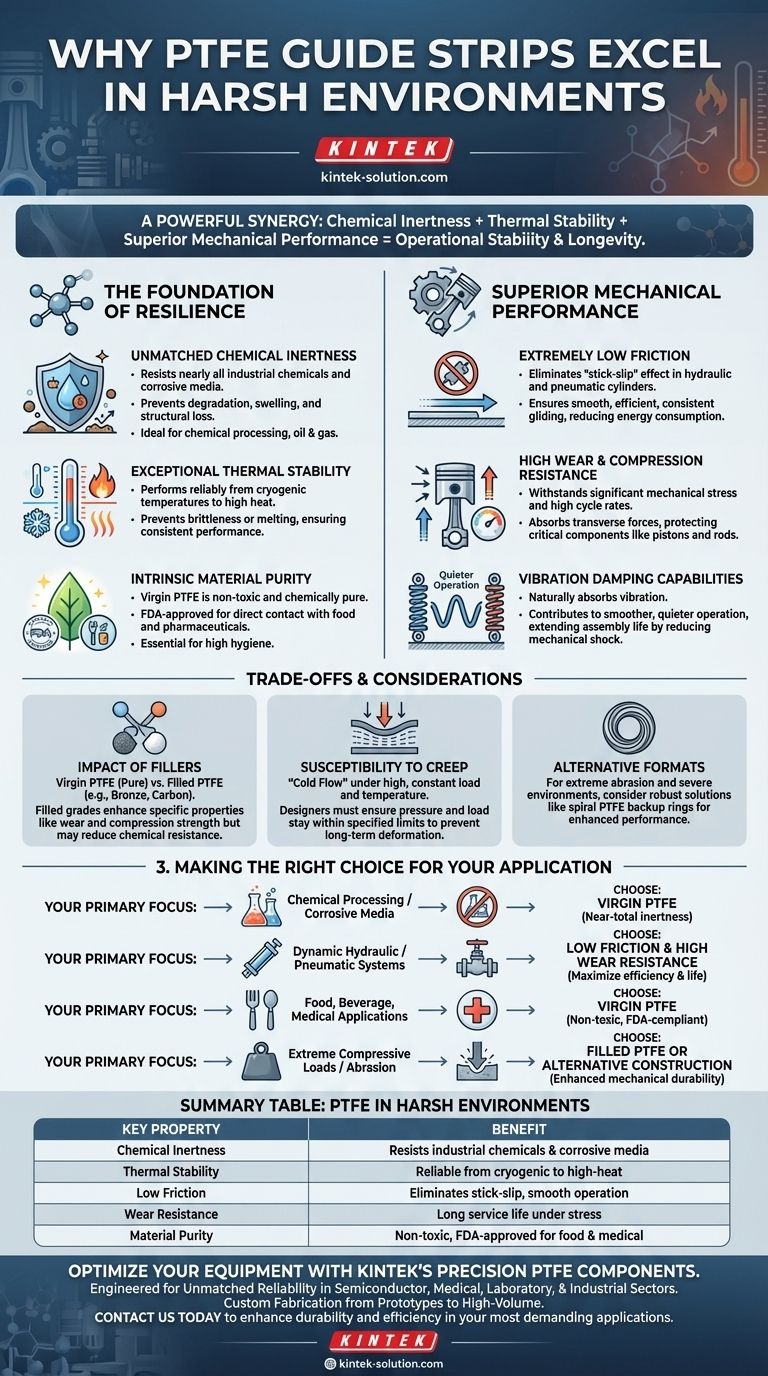

The Foundation of PTFE's Resilience

The core reasons for PTFE's durability are rooted in its molecular structure and purity. This gives it a default resilience before any mechanical considerations are even made.

Unmatched Chemical Inertness

PTFE (Polytetrafluoroethylene) is resistant to nearly all industrial chemicals and corrosive media. This chemical inertness prevents the material from degrading, swelling, or losing its structural integrity when exposed to aggressive substances.

This makes it an ideal choice for applications in chemical processing, oil and gas, and any industry where contact with harsh fluids is unavoidable.

Exceptional Thermal Stability

PTFE guide strips perform reliably across an extremely broad spectrum of temperatures. They maintain their key properties in both cryogenic conditions and high-heat environments where many plastics and elastomers would become brittle or melt.

This thermal stability ensures consistent performance and prevents material failure due to temperature cycling or extreme operational demands.

Intrinsic Material Purity

Many PTFE guide strips are made from virgin PTFE resin, which is non-toxic and chemically pure. This allows the material to be FDA-approved for direct contact with food and pharmaceuticals.

For harsh environments that also require high levels of hygiene, such as food processing or medical device manufacturing, this property is non-negotiable.

Superior Mechanical Performance Under Stress

Beyond simply surviving the environment, PTFE guide strips are designed to actively improve the function of dynamic systems.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. In practical terms, this eliminates the "stick-slip" effect in hydraulic and pneumatic cylinders, where a seal might alternately stick to and release from a surface.

By providing a smooth, consistent gliding surface, it improves the efficiency of dynamic seals, reduces energy consumption, and prevents jerky, uncontrolled movements.

High Wear and Compression Resistance

These guide strips are engineered to withstand significant mechanical stress. Their high wear resistance ensures a long service life, even in applications with frequent movement and high cycle rates.

Furthermore, their high compression resistance allows them to absorb transverse forces, protecting critical components like pistons and rods from metal-to-metal contact and preventing scoring.

Vibration Damping Capabilities

PTFE naturally absorbs a degree of vibration. This vibration damping contributes to quieter, smoother operation and can help extend the life of the entire assembly by reducing mechanical shock on other components.

Understanding the Trade-offs and Considerations

While highly effective, no material is perfect for every scenario. Acknowledging the limitations of PTFE is key to proper application.

The Impact of Fillers

The properties described above apply to virgin PTFE. However, PTFE is often blended with fillers like bronze, carbon, or glass to enhance specific properties.

For instance, a bronze-filled PTFE will have significantly higher compression strength and wear resistance, but its chemical resistance may be slightly reduced. It's critical to match the grade of PTFE to the specific environmental challenge.

Susceptibility to Creep (Cold Flow)

Under a high, constant load, especially at elevated temperatures, PTFE can be susceptible to creep, or "cold flow," where the material slowly deforms over time.

Designers must account for this by ensuring the pressure and load on the guide strip remain within the material's specified limits to prevent long-term deformation.

Alternative Formats for Extreme Abrasion

For the most severe environments involving high temperatures, aggressive chemicals, and abrasive media, a simple guide strip may not be the most robust solution.

In these cases, components like spiral PTFE backup rings offer a more rugged construction that can provide enhanced performance and reliability against a combination of extreme factors.

Making the Right Choice for Your Application

Your specific goal will determine whether PTFE is the optimal choice and which variant to select.

- If your primary focus is chemical processing or corrosive media: Virgin PTFE's near-total chemical inertness is its defining and most valuable feature.

- If your primary focus is dynamic hydraulic or pneumatic systems: The combination of low friction and high wear resistance will maximize efficiency and service life.

- If your primary focus is food, beverage, or medical applications: Virgin PTFE's non-toxic, FDA-compliant nature ensures safety and regulatory adherence.

- If you face extreme compressive loads or abrasion: Consider a filled PTFE grade (like bronze or carbon) or an alternative construction for enhanced mechanical durability.

By understanding these core properties and trade-offs, you can confidently specify PTFE for the environments it was designed to conquer.

Summary Table:

| Key Property | Benefit in Harsh Environments |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals and corrosive media |

| Thermal Stability | Performs reliably from cryogenic to high-heat conditions |

| Low Friction | Eliminates stick-slip, ensures smooth operation |

| Wear Resistance | Provides long service life under mechanical stress |

| Material Purity | Non-toxic, FDA-approved for food and medical use |

Optimize your equipment for harsh environments with KINTEK's precision PTFE components.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our PTFE guide strips, seals, liners, and custom labware are engineered to deliver unmatched reliability. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring your components meet exact specifications for chemical resistance, thermal stability, and mechanical performance.

Contact us today to discuss your project and discover how our PTFE solutions can enhance durability and efficiency in your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry