In short, PTFE-coated O-rings are valuable in the oil and gas industry because they combine the flexible sealing properties of a standard elastomer core with a protective surface that offers exceptional resistance to harsh chemicals, extreme temperatures, and high pressures. This unique combination drastically reduces friction during installation and operation, preventing premature failure in the demanding environments of drilling, extraction, and transport.

The core challenge in oil and gas sealing is finding a material that is both flexible enough to create a tight seal and durable enough to survive chemical and thermal attack. A PTFE-coated O-ring solves this by using the coating not as the primary seal, but as a resilient, low-friction shield for the elastomer core that does the actual work.

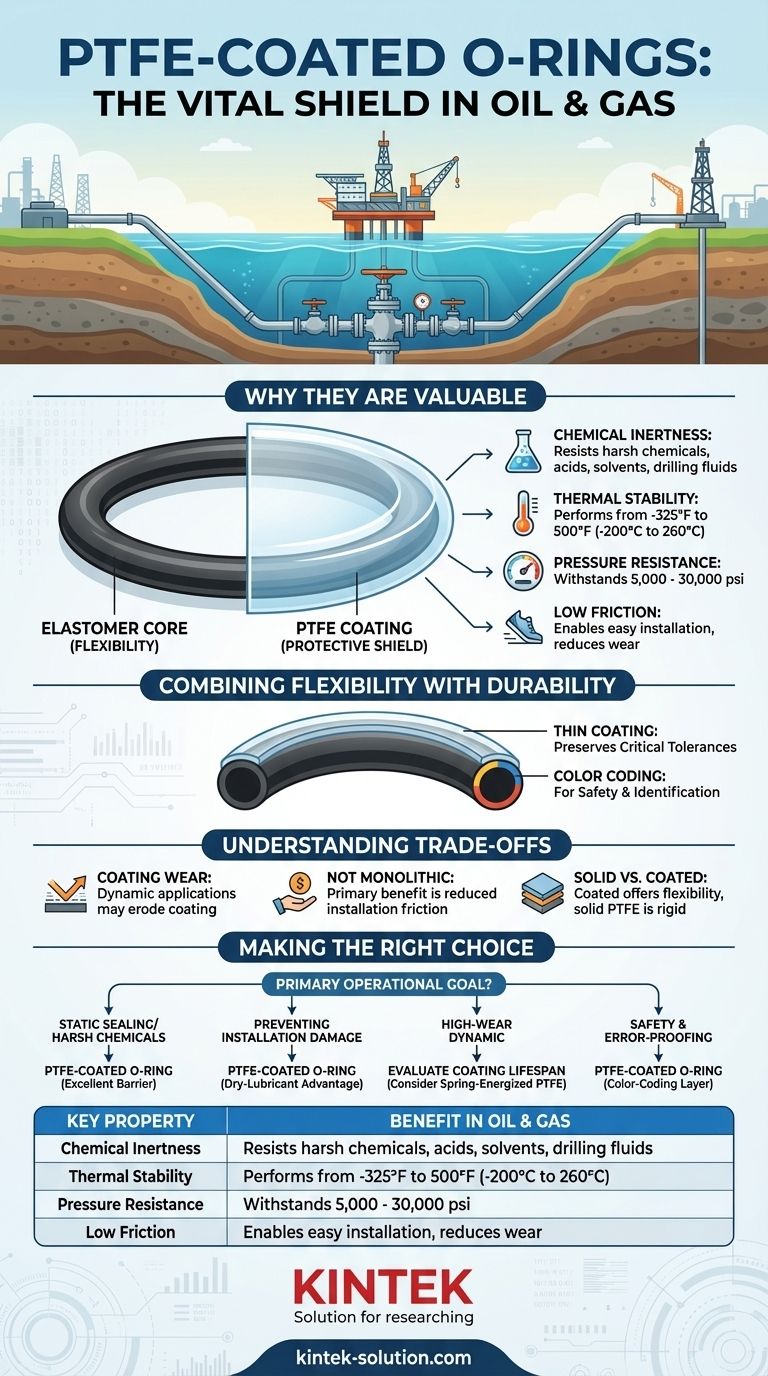

The Core Properties Defining PTFE's Value

The value of PTFE (polytetrafluoroethylene) in demanding applications stems from a unique set of material properties. In the oil and gas sector, where failure is not an option, these attributes directly address the most common points of seal degradation.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including the aggressive acids, solvents, and corrosive drilling fluids common in oil and gas operations. This prevents the O-ring's core material from swelling, cracking, or degrading upon exposure.

Extreme Thermal Stability

Seals in this industry must perform reliably from deep-sea cold to downhole heat. PTFE functions across a vast temperature range, from as low as -325°F to over 500°F (-200°C to 260°C), ensuring the seal maintains its integrity during extreme thermal cycling.

Exceptional Pressure Resistance

Oil and gas systems operate under immense pressure, often ranging from 5,000 to 30,000 psi. While the elastomer core provides the sealing force, the PTFE coating helps the O-ring withstand these pressures without extrusion or damage, making it ideal for high-pressure valves, pumps, and drilling equipment.

The Critical Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is a critical advantage for two reasons: it allows for easier, damage-free installation (acting as a dry lubricant), and it reduces wear and heat generation in dynamic applications.

How a Coating Solves a Deeper Problem

A PTFE-coated O-ring is a composite component, not a solid PTFE ring. This design is intentional, aiming to provide the "best of both worlds" by leveraging the strengths of two different materials.

Combining Flexibility with Durability

A standard elastomer (like FKM or NBR) provides excellent flexibility and memory, allowing it to conform to surfaces and maintain a tight seal. However, it can be vulnerable to friction and chemicals. The thin PTFE coating adds the chemical and friction resistance without compromising the core's vital flexibility.

Preserving Critical Tolerances

The PTFE coatings are engineered to be extremely thin. This ensures that the O-ring's original dimensions and tolerances are not affected, which is crucial for components designed with precise sealing grooves.

Color Coding for Safety and Simplicity

Coatings can be produced in various colors. This provides a simple and effective method for visual part identification, helping technicians ensure the correct O-ring material is used for a specific application and preventing catastrophic failures caused by material incompatibility.

Understanding the Trade-offs and Limitations

While highly effective, it is crucial to understand that a PTFE coating is not an invincible solution. Objectivity requires acknowledging its operational limits.

The Coating Can Wear

In highly dynamic or abrasive applications, the thin PTFE coating can wear away over time. This will eventually expose the underlying elastomer to the conditions it was meant to be shielded from, reducing the seal's long-term performance benefits.

It Is Not a Monolithic Barrier

While the coating provides excellent resistance, it can be porous. Its primary benefit is often the massive reduction in friction during assembly and initial operation, which prevents the nicks and tears that cause most infant O-ring failures.

Solid PTFE vs. Coated Elastomers

It is important to distinguish a PTFE-coated O-ring from a solid PTFE O-ring. A solid PTFE ring offers maximum chemical and thermal resistance but is rigid and has a poor compression set, meaning it doesn't spring back into shape well. The coated version is designed for applications where the flexibility of an elastomer is still required.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the component's strengths to your primary operational goal.

- If your primary focus is static sealing in harsh chemical environments: A PTFE-coated O-ring provides an excellent protective barrier that extends the life of the elastomer core.

- If your primary focus is preventing installation damage: The dry-lubricant property of the PTFE coating is a decisive advantage, ensuring a smooth, tear-free installation.

- If your primary focus is a high-wear, dynamic application: You must critically evaluate whether the coating's lifespan is sufficient or if a more robust solution, like a spring-energized PTFE seal, is necessary.

- If your primary focus is operational safety and error-proofing: The ability to color-code parts provides an invaluable layer of process control during assembly and maintenance.

Ultimately, choosing a PTFE-coated O-ring is a strategic decision to enhance the installation integrity and chemical resilience of a seal in the unforgiving conditions of the oil and gas industry.

Summary Table:

| Key Property | Benefit in Oil & Gas |

|---|---|

| Chemical Inertness | Resists acids, solvents, and drilling fluids to prevent degradation. |

| Thermal Stability | Performs reliably from -325°F to 500°F (-200°C to 260°C). |

| Pressure Resistance | Withstands high pressures (5,000-30,000 psi) without extrusion. |

| Low Friction | Enables easy installation and reduces wear in dynamic applications. |

Need a reliable sealing solution for your demanding oil and gas application?

PTFE-coated O-rings from KINTEK are engineered to solve the toughest challenges in the semiconductor, medical, laboratory, and industrial sectors. We combine precision manufacturing with custom fabrication—from prototypes to high-volume orders—to deliver components that enhance performance and prevent failure.

Contact KINTEK today to discuss how our PTFE components can bring durability and reliability to your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability