To ensure optimal performance, maintenance for PTFE-lined plug valves must be a proactive, four-part strategy: regular inspection for wear, thorough cleaning to prevent contamination, strategic lubrication of external moving parts, and periodic leakage testing to verify sealing integrity. These practices are not just about fixing problems but about preventing failure in systems where reliability and purity are paramount.

The core principle of maintaining a PTFE-lined valve is not to treat it as a simple mechanical part, but as a critical system component. Your goal is to preserve the integrity of the PTFE liner, which is the key to the valve's corrosion resistance and leak-free performance.

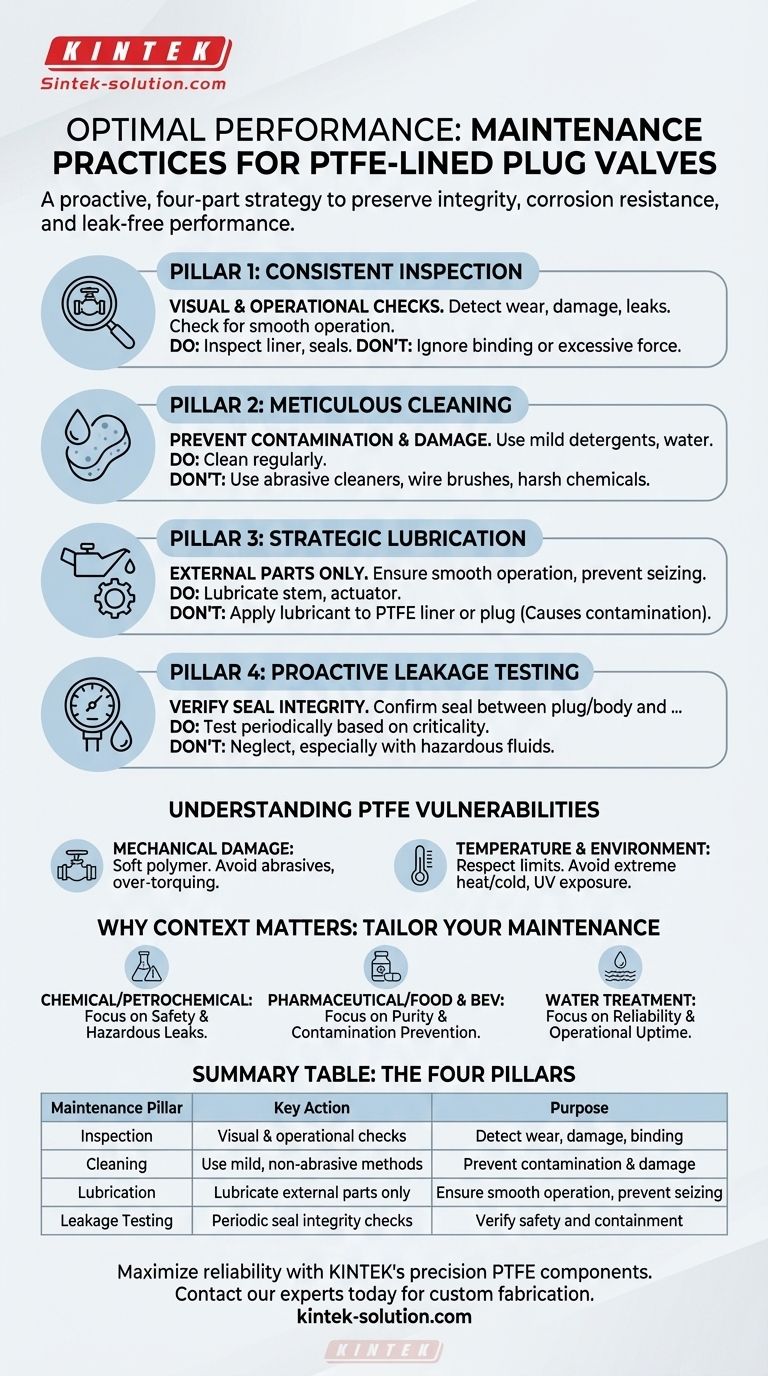

The Four Pillars of Effective Valve Maintenance

Effective maintenance is built on a foundation of consistent, scheduled activities. Each pillar addresses a specific failure mode and collectively ensures long-term reliability.

Pillar 1: Consistent Inspection

Regular inspection is your first line of defense against unexpected failure. It involves both looking at the valve and operating it.

Visually inspect the valve's exterior for any signs of corrosion, damage, or leaks around gaskets and seals. Check the PTFE liner itself (where visible) for discoloration, blistering, or delamination.

Operationally, turn the valve through its full range of motion. It should operate smoothly without requiring excessive force. Any binding or stiffness can indicate internal issues or a need for actuator lubrication.

Pillar 2: Meticulous Cleaning

The PTFE liner provides a non-stick, pure surface, but it must be kept clean to maintain that advantage, especially in sensitive applications.

Contaminants or abrasive particles can damage the soft PTFE surface, creating scratches that compromise its integrity and potentially lead to contamination.

Clean liners with mild detergents and water. Crucially, avoid abrasive cleaners, wire brushes, or harsh chemicals that are not compatible with PTFE, as these can permanently damage the surface.

Pillar 3: Strategic Lubrication

Proper lubrication reduces operational friction, but it is critical to know what to lubricate and what to leave alone.

Lubrication is for external moving parts, such as the valve stem and actuator. This ensures smooth, low-torque operation and prevents parts from seizing.

Never apply lubricant to the PTFE liner or plug. The self-lubricating nature of PTFE is one of its key features. Introducing external lubricants to the process-wetted surfaces can cause contamination and interfere with valve performance.

Pillar 4: Proactive Leakage Testing

A plug valve's primary function is to provide a tight seal. Periodic testing verifies this critical function.

Leakage testing confirms the integrity of the seal between the plug and the body liner, as well as the external seals around the stem. This is especially vital when handling hazardous or high-purity fluids.

The frequency and method of testing should align with the criticality of the service. A valve in a toxic chemical line warrants more frequent testing than one in a low-pressure water system.

Understanding the Vulnerabilities of PTFE

While highly effective, PTFE is not indestructible. Understanding its limitations is key to proper maintenance and avoiding common pitfalls.

Susceptibility to Mechanical Damage

PTFE is a relatively soft polymer. Abrasive slurries, improper cleaning tools, or debris in the line can scratch or gouge the liner, creating a potential leak path.

Over-torquing the valve during operation or tightening flange bolts unevenly during installation can create mechanical stress. This can deform the liner and compromise the seal.

Temperature and Environmental Limits

PTFE has specific temperature limits. Operating the valve in environments that are too hot or too cold can cause the material to degrade, lose its mechanical properties, and fail prematurely.

Similarly, direct sunlight and UV exposure can degrade PTFE over time. While the valve body offers protection, proper storage of spare parts is essential.

Why Context Matters for Your Industry

The consequence of valve failure varies by application, which should directly influence your maintenance priorities.

In Chemical and Petrochemical Processing: The primary goal is preventing hazardous leaks. Maintenance must focus on seal integrity and testing to ensure operator safety and environmental protection.

In Pharmaceutical and Food & Beverage: The priority is purity. Maintenance must center on meticulous cleaning protocols to prevent contamination and regular inspection of the liner to ensure no material is shedding into the product.

In Water Treatment: Reliability is key. Consistent operational checks and actuator lubrication ensure the valves respond as needed for controlling the flow of disinfectants and other treatment chemicals.

Making the Right Choice for Your Goal

Tailor your maintenance schedule based on your most critical operational driver.

- If your primary focus is safety and hazardous material containment: Prioritize frequent leakage testing and visual inspections for any sign of liner degradation or external corrosion.

- If your primary focus is product purity and preventing contamination: Emphasize meticulous, non-abrasive cleaning protocols and regular checks for liner integrity to avoid particle shedding.

- If your primary focus is operational uptime and reliability: Institute a strict schedule of operational checks and strategic lubrication of actuators to prevent seizure or difficult operation.

Ultimately, proactive and informed maintenance transforms your valves from a potential liability into a consistently reliable asset.

Summary Table:

| Maintenance Pillar | Key Action | Purpose |

|---|---|---|

| Inspection | Visual & operational checks | Detect wear, damage, or binding early |

| Cleaning | Use mild, non-abrasive methods | Prevent contamination & liner damage |

| Lubrication | Lubricate external parts only | Ensure smooth operation, prevent seizing |

| Leakage Testing | Periodic seal integrity checks | Verify safety and containment |

Maximize the reliability of your fluid systems with KINTEK's precision PTFE components.

Our expertise in manufacturing high-performance PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors ensures you get components built for durability and purity. A proactive maintenance plan starts with parts you can trust.

Let's discuss your specific application needs. Contact our experts today for custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the size and thickness ranges available for PTFE washers? Find the Perfect Fit for Your Application

- Why is cryogenic deburring particularly suitable for Teflon parts? Achieve a Perfect, Damage-Free Finish

- How do filler materials affect PTFE seal properties? Enhance Performance for Demanding Applications

- What are the key features of PTFE V-Rings? Master Sealing in Extreme Environments

- What are the key properties of Teflon bearings? Engineered for Extreme Environments

- What are the advantages of PTFE in chemically aggressive environments? Unmatched Chemical Resistance & Reliability

- What are the practical advantages of ePTFE gaskets in installation? Simplify Sealing with On-Site Fabrication

- What are the advantages of PTFE gaskets? Superior Sealing for Extreme Chemical & Thermal Environments