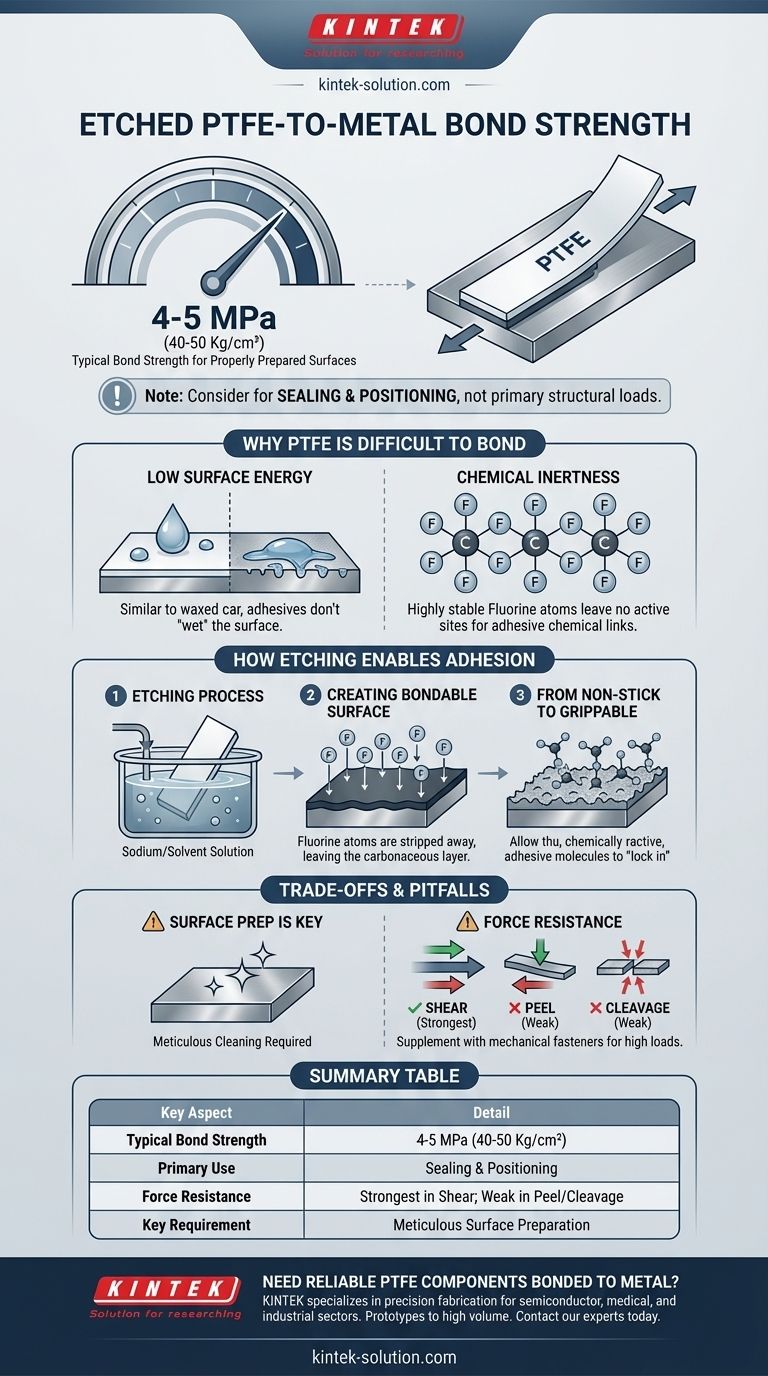

For a properly prepared surface, the typical bond strength of etched Polytetrafluoroethylene (PTFE) to metal is 4-5 Megapascals (MPa), which is equivalent to 40-50 Kg/cm². While this chemical treatment makes bonding possible, the resulting strength is modest and requires careful engineering consideration, especially in applications involving significant mechanical stress.

While etching transforms PTFE from a non-stick material to a bondable one, the resulting adhesive bond should be seen as a positioning or sealing mechanism rather than a primary structural component for high-load applications.

Why PTFE is Inherently Difficult to Bond

Understanding why PTFE resists adhesion is crucial to appreciating the role of etching and the limitations of the final bond. Two core properties are responsible for its famous non-stick nature.

The Role of Surface Energy

PTFE has one of the lowest surface energies of any solid. Think of how water beads up on a freshly waxed car; it doesn't "wet" the surface. Adhesives behave similarly on raw PTFE, unable to spread out and make the intimate contact required for a strong bond.

Chemical Inertness

The molecular structure of PTFE consists of a carbon backbone completely sheathed in highly stable fluorine atoms. This makes the material exceptionally non-reactive and resistant to chemicals, but it also means there are no "active" sites for an adhesive to form a chemical link.

How Etching Enables Adhesion

Etching is a chemical process designed to fundamentally alter the surface of PTFE, overcoming its natural resistance to bonding.

The Etching Process Explained

The most common method involves exposing the PTFE to a solution of sodium in a solvent like naphthalene. This aggressive chemical agent physically strips fluorine atoms from the PTFE polymer chains on the surface.

Creating a Bondable Surface

This defluorination process leaves behind a carbonaceous, dark-brown layer. This new surface is chemically reactive and has a much higher surface energy, making it receptive to adhesives.

From Non-Stick to Grippable

Think of etching as chemically "sanding" a perfectly smooth, glossy surface before painting. It creates a microscopic texture and a chemically active foundation that allows the adhesive (the "paint") to securely lock in place.

Understanding the Trade-offs and Pitfalls

Achieving the 4-5 MPa benchmark is not automatic. The process is sensitive, and the resulting bond has specific limitations that must be respected in any design.

Proper Preparation is Non-Negotiable

The quoted bond strength assumes ideal conditions. Both the etched PTFE and the metal substrate must be meticulously cleaned and free of any contaminants like oils, dust, or moisture before the adhesive is applied.

The Bond is Strongest in Shear

An adhesive bond on PTFE performs best when the forces are in shear (parallel to the bond line). It is significantly weaker against peel or cleavage forces, which concentrate stress on the leading edge of the bond and can cause it to unzip.

Over-reliance on Adhesion Alone

As the reference material indicates, this bond strength is often insufficient for high-load applications. It is a common and prudent engineering practice to supplement the adhesive bond with mechanical support, such as clamps, bolts, or an interlocking physical design.

Making the Right Choice for Your Goal

Use the nature of the mechanical stress in your application as the primary guide for how to implement a PTFE-to-metal bond.

- If your primary focus is sealing or static positioning: An adhesive-only bond on properly etched and prepared PTFE is often a viable and effective solution.

- If your application involves significant vibration, shear, or peel forces: You must supplement the adhesive bond with mechanical fasteners to ensure long-term reliability.

- If you require a true structural bond: PTFE is likely the wrong material for the application, and you should consider alternatives like PEEK or other high-performance polymers.

By treating the adhesive as a complement to a mechanical design rather than a replacement for it, you can successfully leverage PTFE's unique properties without falling victim to its inherent bonding limitations.

Summary Table:

| Key Aspect | Detail |

|---|---|

| Typical Bond Strength | 4-5 MPa (40-50 Kg/cm²) |

| Primary Use | Sealing & Positioning (not high-load structural) |

| Force Resistance | Strongest in shear; weak against peel/cleavage |

| Key Requirement | Meticulous surface preparation is critical |

Need reliable PTFE components bonded to metal? KINTEK specializes in the precision fabrication of PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise ensures your components are designed and manufactured for optimal performance, whether you need prototypes or high-volume orders. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability