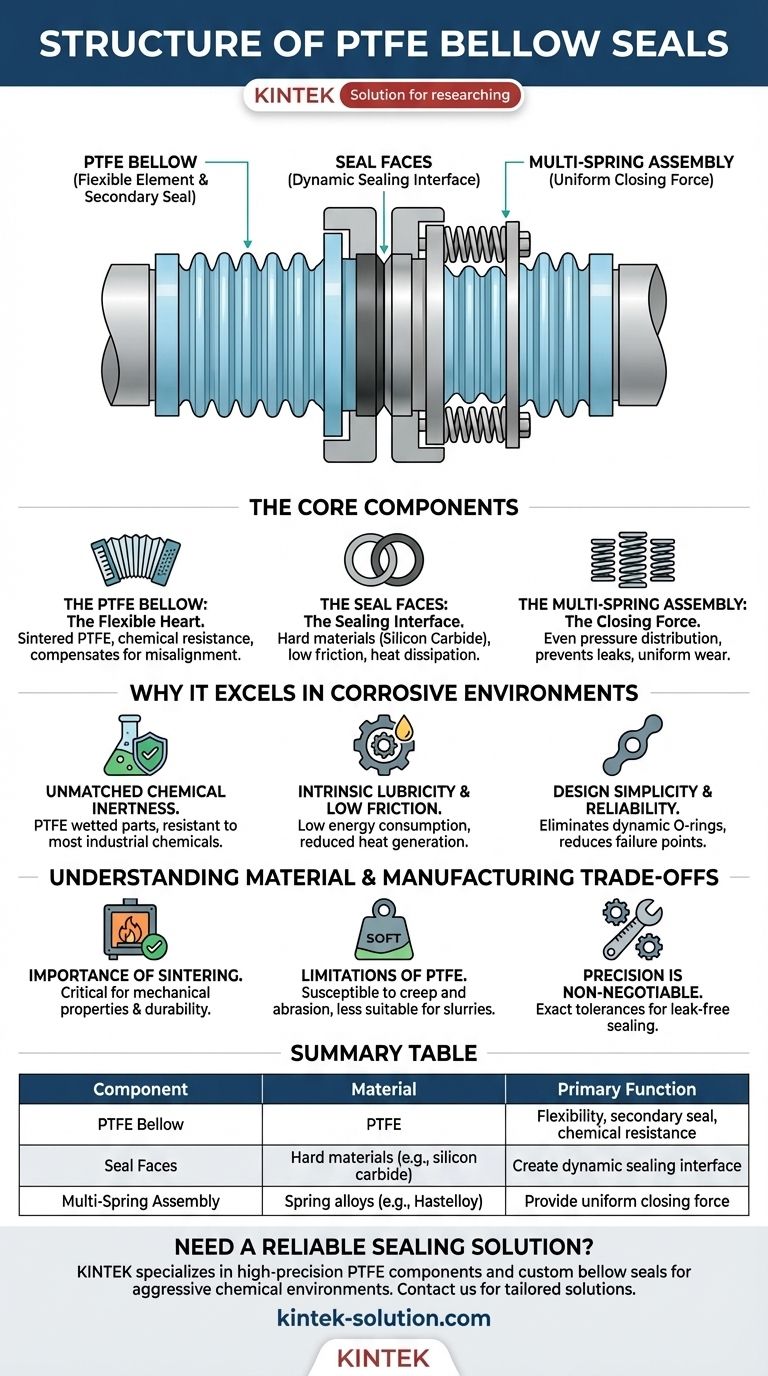

Fundamentally, a PTFE bellow seal is a composite assembly engineered for exceptional chemical resistance and mechanical flexibility. Its core structure consists of three main parts: a flexible, convoluted bellow made from Polytetrafluoroethylene (PTFE), a set of seal faces that create the dynamic seal, and a multi-spring mechanism that provides the necessary closing force. This design uniquely eliminates the need for traditional elastomeric O-rings in the dynamic sealing area.

The critical insight is that a PTFE bellow seal’s structure is not just a collection of parts, but an integrated system. The bellow itself serves as both the flexible element and the secondary seal, leveraging PTFE's chemical inertness to provide a robust solution for sealing highly corrosive fluids.

The Core Components of a PTFE Bellow Seal

A deeper look at the components reveals how the seal functions as a cohesive unit, especially within demanding applications like corrosion-resistant pumps.

The PTFE Bellow: The Flexible Heart

The central component is the bellow itself. It is formed from high-quality PTFE resins that are pressed, heat-treated through a process called sintering, and then machined to a precise, convoluted shape.

This accordion-like structure gives the seal its essential flexibility, allowing it to compensate for shaft misalignment, axial movement, and vibration without losing its seal.

Crucially, the bellow also functions as the secondary seal, preventing leakage along the pump shaft. Because it is made of solid PTFE, it has near-universal chemical resistance.

The Seal Faces: The Sealing Interface

The actual sealing occurs at the interface between a stationary and a rotating seal face (or ring). While the bellow is PTFE, these faces are typically made from much harder materials.

These material pairings (like carbon vs. silicon carbide or ceramic) are chosen for their durability, heat dissipation, and low friction properties. The PTFE bellow's job is to keep these two faces pressed together with consistent force.

The Multi-Spring Assembly: The Closing Force

To maintain contact between the seal faces, a multi-spring structure is used. These springs are located outside the direct fluid path, protecting them from the corrosive process media.

Using multiple springs, rather than one large one, distributes the closing force more evenly around the seal faces. This uniform pressure is critical for preventing leaks and ensuring even wear over the seal's operational life.

Why This Structure Excels in Corrosive Environments

The specific combination of a PTFE bellow, hard faces, and external springs is a deliberate engineering choice to solve the unique challenges of aggressive chemical applications.

Unmatched Chemical Inertness

The primary reason for this design is the use of PTFE for all "wetted" parts. PTFE is inert to nearly all industrial chemicals, making it the ideal choice for applications where rubber or other elastomers would quickly degrade.

Intrinsic Lubricity and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This high lubricity is a significant advantage, reducing the heat generated between the seal faces and lowering the energy needed to turn the pump shaft.

Design Simplicity and Reliability

By integrating the flexible element and the secondary seal into a single PTFE bellow, the design eliminates a common failure point in other seals: the dynamic O-ring. This makes the seal simpler and more reliable in the long term.

Understanding the Material and Manufacturing Trade-offs

While highly effective, the structure and material of a PTFE bellow seal come with specific considerations that are important to understand.

The Importance of Sintering

The manufacturing process is critical. The raw PTFE resin must be properly sintered (a heat treatment process) to enhance its mechanical properties and durability. Improperly processed material can lead to premature failure.

Limitations of PTFE

Despite its chemical resistance, PTFE is a relatively soft material compared to metals. It can be susceptible to "creep" (slow deformation) under high pressure and temperature, and it is less abrasion-resistant than harder materials. This makes it less suitable for abrasive slurry applications.

Precision is Non-Negotiable

The final seal components must be finished to precise dimensions, often using CNC machining. The flatness of the seal faces and the exact tolerances of the bellow are paramount for achieving a leak-free seal.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its structural benefits to your primary operational goal.

- If your primary focus is handling highly aggressive chemicals: The key feature is the all-PTFE construction of the bellow, which ensures complete chemical compatibility.

- If your primary focus is accommodating shaft misalignment or vibration: The flexible, convoluted design of the bellow provides the necessary forgiveness for dynamic pump conditions.

- If your primary focus is long-term reliability in corrosive service: The integrated bellow design, which removes the dynamic O-ring, and the uniform pressure from the multi-spring assembly are the most critical structural elements.

Ultimately, the structure of a PTFE bellow seal is a masterclass in material-driven design, leveraging the unique properties of PTFE to achieve reliable sealing where other materials would fail.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| PTFE Bellow | Polytetrafluoroethylene (PTFE) | Flexibility, secondary seal, chemical resistance |

| Seal Faces | Hard materials (e.g., silicon carbide) | Create the dynamic sealing interface |

| Multi-Spring Assembly | Spring alloys (e.g., Hastelloy) | Provide uniform closing force to the seal faces |

Need a reliable sealing solution for aggressive chemicals?

The structure of a PTFE bellow seal is engineered for maximum performance in corrosive environments. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bellow seals, for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that perfectly matches your application's demands for chemical resistance, flexibility, and long-term reliability.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution tailored for you.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions