In essence, sintering is a controlled thermal process that transforms compressed Polytetrafluoroethylene (PTFE) powder into a solid, unified block known as a billet. It involves heating a pre-formed shape to a temperature just above PTFE's melting point, holding it there to allow the individual particles to fuse together, and then cooling it down under very specific conditions. This process is necessary because PTFE does not flow when melted like other plastics.

The core problem with processing PTFE is its extremely high melt viscosity, making traditional melt-extrusion or injection molding impossible. Sintering is the essential manufacturing solution that fuses mechanically compressed PTFE particles into a solid, functional material by carefully controlling heat and time.

Why Sintering is Essential for PTFE

Unlike common thermoplastics that can be simply melted and poured into a mold, PTFE behaves differently. When heated past its melting point, it becomes a translucent, gel-like substance but does not flow.

This unique characteristic means that creating a solid PTFE part requires a multi-stage approach where pressure and heat are applied separately.

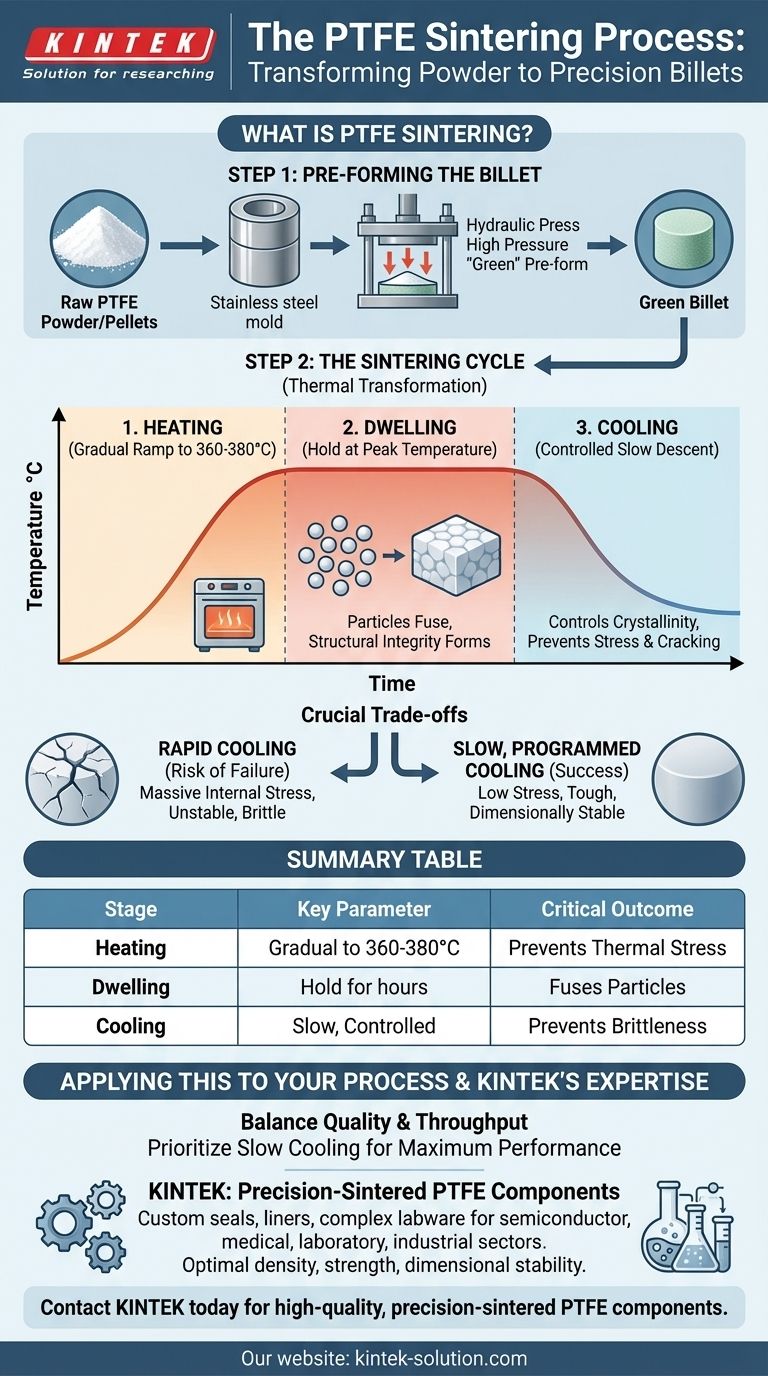

Step 1: Pre-forming the Billet

The process begins not in the oven, but with PTFE powder or pellets. This raw material is poured into a cylindrical mold, typically made of stainless steel.

A hydraulic press is then used to apply significant pressure, compacting the powder into a self-supporting, but still fragile, shape. This object is often called a "green" pre-form or billet.

Step 2: The Sintering Cycle

The green billet is carefully removed from the mold and placed into a programmable sintering oven. The thermal cycle is the most critical phase and consists of three distinct stages.

Heating: The oven temperature is gradually raised to approximately 360-380°C (680-716°F), which is above PTFE's crystalline melting point of around 327°C (621°F).

Dwelling: The billet is held at this peak temperature for several hours. During this "dwell time," the individual PTFE particles, which were only mechanically interlocked, coalesce and fuse on a molecular level. This is where the material gains its structural integrity and mechanical properties.

Cooling: After dwelling, the billet is cooled back to room temperature. This is not a passive step; the cooling rate is precisely controlled to manage the material's final crystallinity, which directly impacts its physical properties and dimensional stability.

Understanding the Critical Trade-offs

The success or failure of producing a high-quality PTFE billet hinges entirely on the precise control of the sintering cycle. Missteps here result in wasted material and poor performance.

The Risk of Improper Heating

If the heating rate is too fast, thermal stresses can build up within the billet, leading to cracks. If the dwell temperature is too low or the time too short, the particles will not fuse completely, resulting in a porous, weak material with poor mechanical strength.

The Critical Role of Controlled Cooling

Rapid cooling is the most common cause of failure. Quenching or cooling a PTFE billet too quickly induces massive internal stresses and creates a brittle, dimensionally unstable product that is prone to cracking.

A slow, programmed cooling ramp is non-negotiable. It allows the polymer chains to re-crystallize in a uniform and low-stress manner, ensuring the final billet is tough and stable for subsequent machining.

Impact on Final Properties

The entire thermal profile—heating rate, dwell temperature, dwell time, and cooling rate—directly determines the final billet's density, tensile strength, elongation, and resistance to wear. A properly sintered billet is a dense, homogenous solid ready for machining into sheets, rods, or complex components.

Applying This to Your Process

Choosing the right parameters is about balancing material quality with production time, but quality cannot be compromised at the fundamental level.

- If your primary focus is maximum material performance: Your process must prioritize a slow, highly controlled cooling cycle. This is the single most important variable for achieving low internal stress and optimal mechanical properties.

- If your primary focus is production throughput: Understand that the dwell and cooling phases are fixed constraints. Attempting to shorten them will directly compromise billet integrity, leading to a higher scrap rate that negates any time saved.

Ultimately, PTFE sintering is a deliberate transformation, not just a heating process, where patience and precision create a uniquely capable material.

Summary Table:

| Sintering Stage | Key Parameter | Critical Outcome |

|---|---|---|

| Heating | Gradual ramp to 360-380°C (680-716°F) | Prevents thermal stress and cracking |

| Dwelling | Hold at peak temperature for several hours | Fuses PTFE particles for structural integrity |

| Cooling | Slow, programmed cooling to room temperature | Controls crystallinity and prevents brittleness |

Need high-quality, precision-sintered PTFE components?

The PTFE sintering process is critical for achieving the material's full potential. At KINTEK, we specialize in manufacturing custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures every part is sintered with precision to deliver optimal density, strength, and dimensional stability.

Let us handle the complexities of PTFE fabrication for you, from prototypes to high-volume orders. Contact KINTEK today to discuss your project requirements and benefit from our material science expertise.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some key properties of Teflon that make it widely useful? Discover Its Unique Advantages

- What are the advantages of polyamide fillers in PTFE? Protect Soft Mating Surfaces with Non-Abrasive Performance

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- Why is PTFE suitable for electrical applications? Discover Its Superior Insulating Properties

- How does Teflon demonstrate superior chemical resistance? Unlocking Its Molecular Fortress

- Which industries commonly use PTFE materials? A Guide to High-Performance Polymer Applications

- How does PTFE demonstrate strong chemical resistance? Unmatched Inertness for Harsh Chemical Environments

- What are some common household uses of Teflon? Discover the Material Science in Your Home