In sublimation printing, PTFE sheets act as an essential protective barrier. They are placed between your substrate and the heat press platen to prevent ink from bleeding onto your equipment, while their unique properties ensure heat is distributed evenly for a flawless, vibrant final print.

The fundamental role of a PTFE sheet is process control. Its non-stick surface and high heat resistance don't just protect your equipment; they are critical for preventing print defects and ensuring the consistent, high-quality results that define professional sublimation.

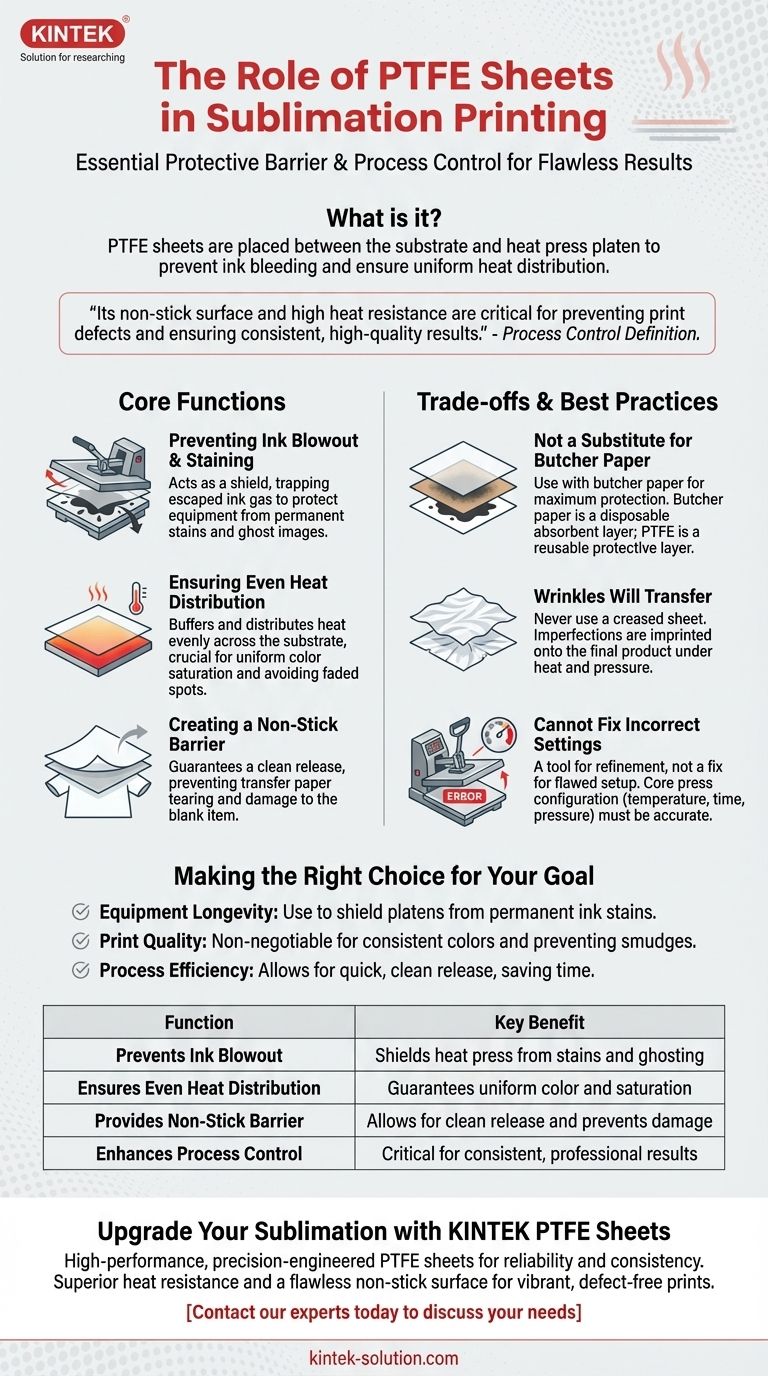

The Core Functions of a PTFE Sheet

The value of a PTFE sheet goes far beyond simple protection. It directly influences the outcome of every press by managing the two most critical variables in sublimation: heat and ink transfer.

Preventing Ink Blowout and Staining

Sublimation works by turning solid ink into a gas. Inevitably, some of this ink gas will escape from the edges of the transfer paper.

A PTFE sheet acts as a shield, trapping this "ink blowout" and preventing it from permanently staining the upper platen of your heat press. This protects both your equipment and your next project from ghost images.

Ensuring Even Heat Distribution

While a heat press platen is designed to be hot, it can have minor temperature variations across its surface.

The PTFE sheet helps buffer and distribute this heat more evenly across the entire substrate. This consistency is crucial for achieving uniform color saturation and avoiding faded or underdeveloped spots in your design.

Creating a Non-Stick Barrier

The high heat of sublimation can cause transfer paper to stick to the platen or even cause certain substrates to become tacky.

The non-stick surface of a PTFE sheet guarantees a clean release every time. This prevents the transfer paper from tearing and protects the delicate surface of your blank item from being damaged upon removal.

Understanding the Trade-offs and Best Practices

While indispensable, understanding how to use a PTFE sheet correctly is key to avoiding common mistakes that can compromise an otherwise perfect print.

Not a Substitute for Butcher Paper

Many professionals use a sheet of unwaxed butcher paper directly on top of their design to absorb excess ink, and then place the PTFE sheet over that.

The butcher paper is a disposable absorbent layer, while the PTFE sheet is a reusable protective layer. Using both offers maximum protection and quality control.

Wrinkles Will Transfer

A significant pitfall is using a creased or wrinkled PTFE sheet.

Any imperfection in the sheet's surface can be imprinted onto your final product under the intense heat and pressure, creating unwanted lines or patterns in your design. Always use a flat, smooth sheet.

It Cannot Fix Incorrect Settings

A PTFE sheet is a tool for refinement, not a fix for a flawed setup.

It can help distribute heat evenly, but it cannot compensate for incorrect temperature, time, or pressure settings. Your core press configuration must be accurate for your specific substrate.

Making the Right Choice for Your Goal

Integrating a PTFE sheet into your sublimation workflow is a simple step that yields significant returns in both quality and efficiency.

- If your primary focus is equipment longevity: Always use a PTFE sheet to shield your heat press platens from permanent ink stains, which protects your investment.

- If your primary focus is print quality: A PTFE sheet is non-negotiable for achieving consistent colors and preventing smudges or ghosting from ink blowout.

- If your primary focus is process efficiency: The non-stick surface allows for a quick, clean release of your product, preventing damage and saving time between presses.

Mastering its use is a foundational step in moving from inconsistent results to reliable, professional-grade sublimation printing.

Summary Table:

| Function | Key Benefit |

|---|---|

| Prevents Ink Blowout | Shields heat press from stains and ghosting |

| Ensures Even Heat Distribution | Guarantees uniform color and saturation |

| Provides Non-Stick Barrier | Allows for clean release and prevents damage |

| Enhances Process Control | Critical for consistent, professional results |

Upgrade your sublimation process with precision-engineered PTFE sheets from KINTEK.

As specialists in high-performance PTFE components for demanding industries, we understand the critical need for reliability and consistency in your printing workflow. Our PTFE sheets are manufactured to the highest standards, offering superior heat resistance and a flawless non-stick surface to protect your equipment and ensure vibrant, defect-free prints every time.

Whether you need a standard size or a custom-fabricated solution for a unique application, KINTEK delivers the quality and precision you require.

Contact our experts today to discuss your needs and discover how our PTFE solutions can enhance your print quality and protect your investment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection