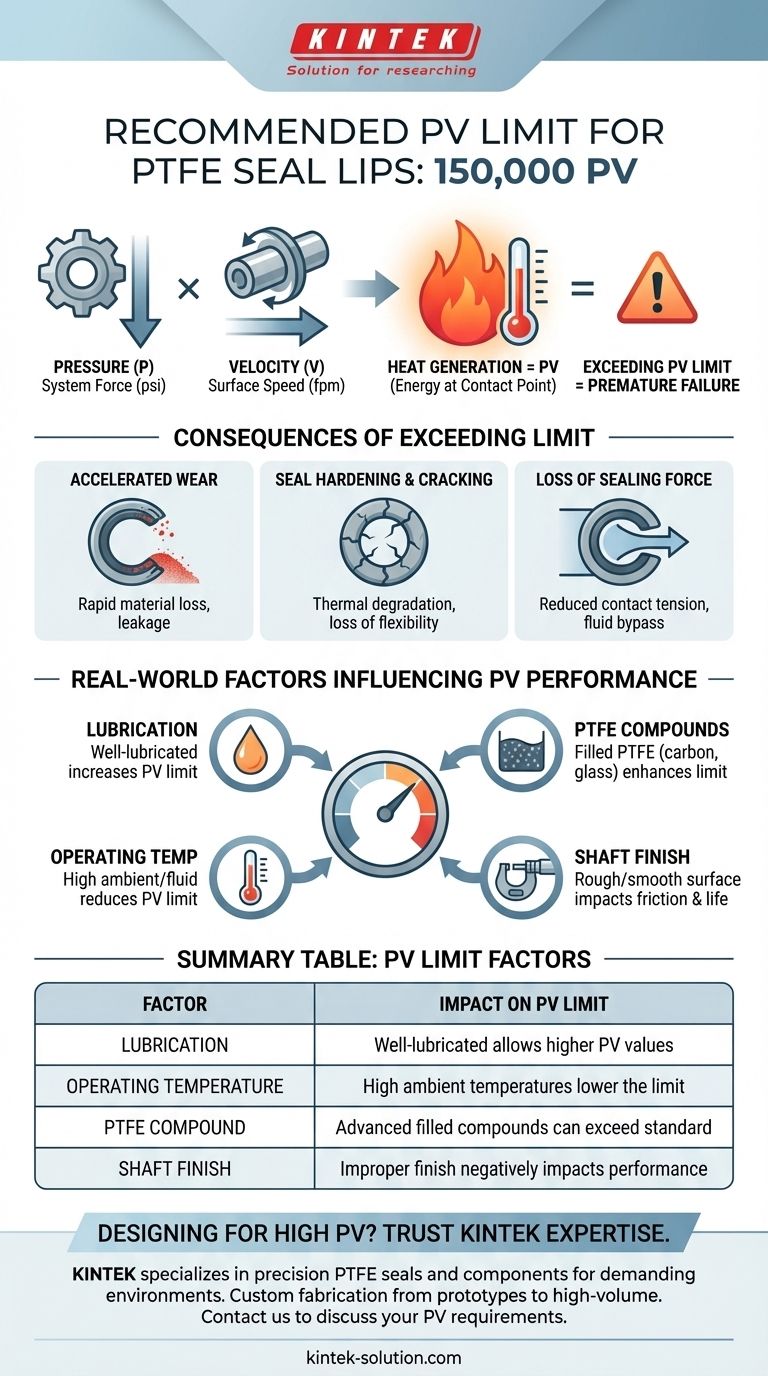

For PTFE seal lips, the generally accepted PV (Pressure-Velocity) limit is 150,000. This value represents the maximum combination of pressure and velocity the seal can typically withstand before heat generation leads to accelerated wear and potential failure.

The concept of a PV limit is not just a material specification; it's a fundamental design principle for managing frictional heat. Exceeding the recommended 150,000 PV for PTFE risks creating temperatures at the seal-shaft interface that degrade the material and compromise the entire sealing system.

What is PV and Why Does It Matter?

Understanding the PV limit is critical for designing reliable rotating equipment. It is the single most important factor in predicting the thermal performance and lifespan of a rotary shaft seal.

Defining Pressure (P)

Pressure, in this context, is the system pressure (in psi) being sealed. This force pushes the flexible seal lip against the rotating shaft, creating the contact band necessary for sealing.

Defining Velocity (V)

Velocity is the linear surface speed of the shaft (in feet per minute, or fpm). It is not simply the rotational speed (RPM), but a function of RPM and shaft diameter. A larger shaft rotating at the same RPM will have a higher surface velocity.

The Critical Relationship: Heat Generation

The PV value is a direct indicator of the amount of energy and frictional heat being generated at the tiny contact point between the seal lip and the shaft. PV = Heat. If this heat cannot be dissipated effectively, the seal's temperature will rise dramatically.

The Consequences of Exceeding the PV Limit

Pushing a PTFE seal beyond its recommended PV limit is a direct path to premature failure. The excessive heat generated at the contact point causes a cascade of damaging effects.

Accelerated Wear

As the PTFE material heats up, it softens and its wear resistance plummets. This leads to a rapid loss of material from the seal lip, widening the contact band and eventually causing leakage.

Seal Hardening and Cracking

Sustained high temperatures can thermally degrade the PTFE polymer itself. The material becomes hard and brittle, losing the flexibility required to conform to the shaft surface, which results in cracks and catastrophic leakage.

Loss of Sealing Force

Excessive heat can also cause the seal lip to lose its designed-in tension. This reduces the contact force against the shaft, allowing fluid to easily bypass the seal.

Understanding the Real-World Factors

The 150,000 PV value is a guideline, not an absolute law. Several real-world operating conditions can significantly influence a seal's actual performance limit.

Lubrication Conditions

The presence and type of lubrication is the most significant factor. A well-lubricated interface reduces friction and helps carry away heat, potentially allowing for operation at higher PV values. A dry-running application, by contrast, will have a much lower effective PV limit.

Operating Temperature

The seal's ability to dissipate heat depends on the temperature of its surrounding environment. A high ambient or fluid temperature reduces the thermal gradient, making it harder for the seal to cool itself and effectively lowering its maximum allowable PV.

PTFE Compounds and Fillers

Not all PTFE is the same. Base PTFE is often blended with fillers like carbon, graphite, or glass to enhance properties like wear resistance and thermal conductivity. These advanced compounds can often operate at higher PV values than standard PTFE.

Shaft Hardness and Surface Finish

A rough shaft finish will act like a file, dramatically increasing friction and wear. Conversely, an extremely smooth shaft can inhibit the formation of a lubricating film. Both conditions can negatively impact the seal's life and its ability to handle high PV.

Making the Right Choice for Your Application

Use the PV calculation as a primary tool for system design and seal selection. A conservative approach is always recommended to ensure long-term reliability.

- If your primary focus is high pressure at low speed: Pay close attention to the seal's material strength and design to prevent extrusion, as PV is less likely to be the limiting factor.

- If your primary focus is high speed at low pressure: Your design must prioritize thermal management, ensuring excellent lubrication and a path for heat to dissipate from the seal area.

- If your application approaches the 150,000 PV limit: Consider using advanced filled-PTFE compounds, improving surface finish and lubrication, and implementing a rigorous testing protocol to validate the design.

Ultimately, treating the PV limit as a critical design constraint is the key to engineering a robust and reliable sealing system.

Summary Table:

| Factor | Impact on PV Limit |

|---|---|

| Lubrication | Well-lubricated interfaces can allow for higher PV values. |

| Operating Temperature | High ambient temperatures effectively lower the PV limit. |

| PTFE Compound | Advanced filled compounds (carbon, glass) can exceed standard PTFE limits. |

| Shaft Finish | Improper surface finish (too rough or smooth) negatively impacts PV performance. |

Designing for high PV applications? KINTEK specializes in manufacturing precision PTFE seals and components for demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your sealing systems are reliable and perform at the limit. Contact us today to discuss your specific PV requirements and receive a solution tailored for long-term performance. Get in touch via our contact form

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability