In mechanical equipment, the purpose of PTFE gasket material is to serve a critical dual role. It provides a highly effective and reliable seal to prevent leaks, while its unique properties simultaneously offer excellent lubrication to reduce friction and wear between moving components. This combination enhances the overall efficiency, longevity, and reliability of the machinery.

The core value of PTFE lies beyond simple sealing. Its unique combination of chemical inertness, an extremely low friction coefficient, and wide temperature tolerance makes it a high-performance material that both seals critical systems and lubricates their moving parts.

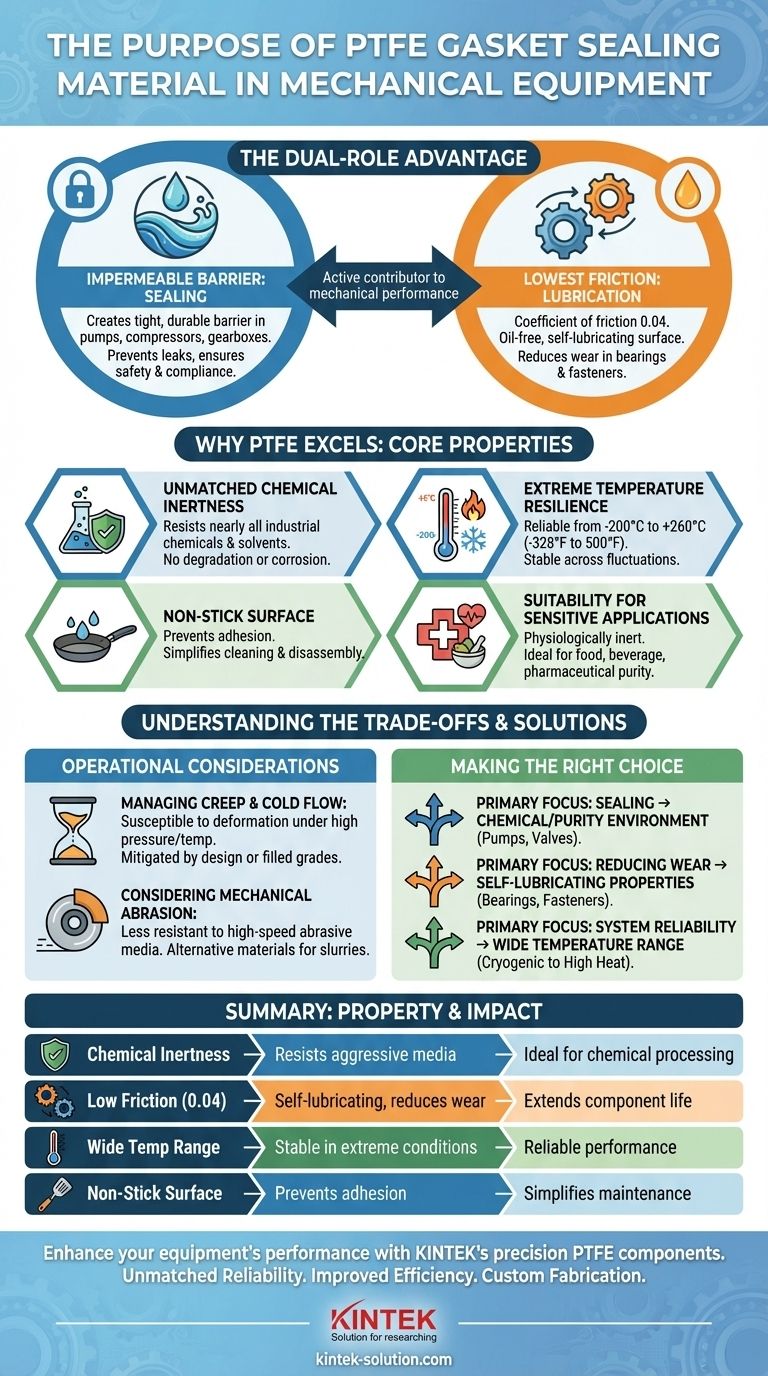

The Dual-Role Advantage: Sealing and Lubrication

Polytetrafluoroethylene (PTFE) is not just a passive barrier; it is an active contributor to mechanical performance. Its function can be broken down into two primary responsibilities.

Creating an Impermeable Barrier

The most fundamental purpose of any gasket is to seal. PTFE excels at creating a tight, durable barrier in components like pumps, compressors, and gearboxes.

This prevents the leakage of fluids or gases, which is essential for equipment safety, efficiency, and environmental compliance.

The Lowest Friction of Any Solid

PTFE has a coefficient of friction of just 0.04, the lowest of any known solid material. This property makes it an ideal oil-free, self-lubricating surface.

In applications like fastening bolts, nuts, and bearing assemblies, PTFE gaskets reduce friction and wear, allowing for smoother operation and extending the service life of the components.

Protecting Against Contaminants

Beyond sealing in fluids, PTFE gaskets also provide essential protection by sealing out external contaminants.

This function provides critical dust and water protection, safeguarding sensitive internal mechanisms from damage and premature failure.

Why PTFE Excels: Core Material Properties

PTFE's effectiveness is a direct result of its unique molecular structure, which gives it several key advantages in demanding industrial environments.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This chemical inertness ensures the seal will not degrade, corrode, or react with the substances it contains, even in highly aggressive applications.

Extreme Temperature Resilience

PTFE performs reliably across an exceptionally wide temperature range, from cryogenic conditions at -200°C (-328°F) up to high-heat applications at +260°C (500°F).

This stability allows it to be used in systems that experience significant temperature fluctuations without compromising the integrity of the seal.

Non-Stick Surface

The material's non-stick, or non-adhesion, characteristics prevent other materials from bonding to its surface. This simplifies disassembly and cleaning during maintenance and ensures the seal releases cleanly.

Suitability for Sensitive Applications

Because PTFE is physiologically inert, it does not contaminate the materials it comes into contact with. This makes it a preferred choice for applications in the food, beverage, and pharmaceutical industries where purity is paramount.

Understanding the Trade-offs

While PTFE is a high-performance material, objectivity requires acknowledging its operational considerations. No single material is perfect for every scenario.

Managing Creep and Cold Flow

PTFE is a relatively soft material. Under sustained high pressure, especially at elevated temperatures, it can be susceptible to "creep" or "cold flow," where the material slowly deforms over time.

This is often mitigated through proper gasket design, such as incorporating an elastic inner core or using filled PTFE grades that add rigidity and improve deformation resistance.

Considering Mechanical Abrasion

While its low friction prevents wear in sliding contacts, pure PTFE is not as resistant to high-speed abrasive media as harder materials.

In applications involving abrasive slurries, a different material or a reinforced composite seal might be a more durable choice.

Making the Right Choice for Your Goal

Selecting a sealing material should be based on the primary demand of the application.

- If your primary focus is sealing in a chemically aggressive or high-purity environment: PTFE's unmatched chemical inertness makes it the definitive choice for pumps, valves, and vessels.

- If your primary focus is reducing wear and friction in moving parts: Its self-lubricating properties are ideal for improving the service life of bearing assemblies and fastener threads.

- If your primary focus is system reliability across a wide temperature range: PTFE's thermal stability ensures a consistent and effective seal from cryogenic lows to high operational heat.

Ultimately, selecting PTFE is a strategic decision to enhance both the reliability and efficiency of your mechanical systems.

Summary Table:

| Property | Benefit | Application Impact |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Ideal for aggressive media in chemical processing |

| Low Friction (0.04) | Self-lubricating, reduces wear | Extends life of bearings and fasteners |

| Wide Temp Range (-200°C to +260°C) | Stable in extreme conditions | Reliable performance from cryogenics to high heat |

| Non-Stick Surface | Prevents adhesion, easy cleaning | Simplifies maintenance and disassembly |

Enhance your equipment's performance with KINTEK's precision PTFE components.

Our PTFE seals, liners, and labware are engineered for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We combine precision manufacturing with deep material expertise to deliver solutions that offer:

- Unmatched Reliability: Prevent leaks and reduce downtime with seals built for chemical resistance and thermal stability.

- Improved Efficiency: Lower friction means less energy consumption and longer component life.

- Custom Fabrication: From initial prototypes to high-volume production, we tailor solutions to your exact specifications.

Let's discuss how our PTFE expertise can solve your specific sealing and lubrication challenges. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs