At its core, the Polytetrafluoroethylene (PTFE) lining process is a method of applying a thin, non-stick, and chemically inert layer of PTFE to the interior surface of another component. The universal process involves meticulously cleaning the substrate, applying the PTFE layer, using heat to bond it permanently, and inspecting the final product for a flawless finish.

The key to understanding PTFE lining is recognizing it's not a single technique, but a multi-step procedure. Success depends equally on the flawless preparation of the surface and the specific application method chosen, which is dictated by the component's shape and intended use.

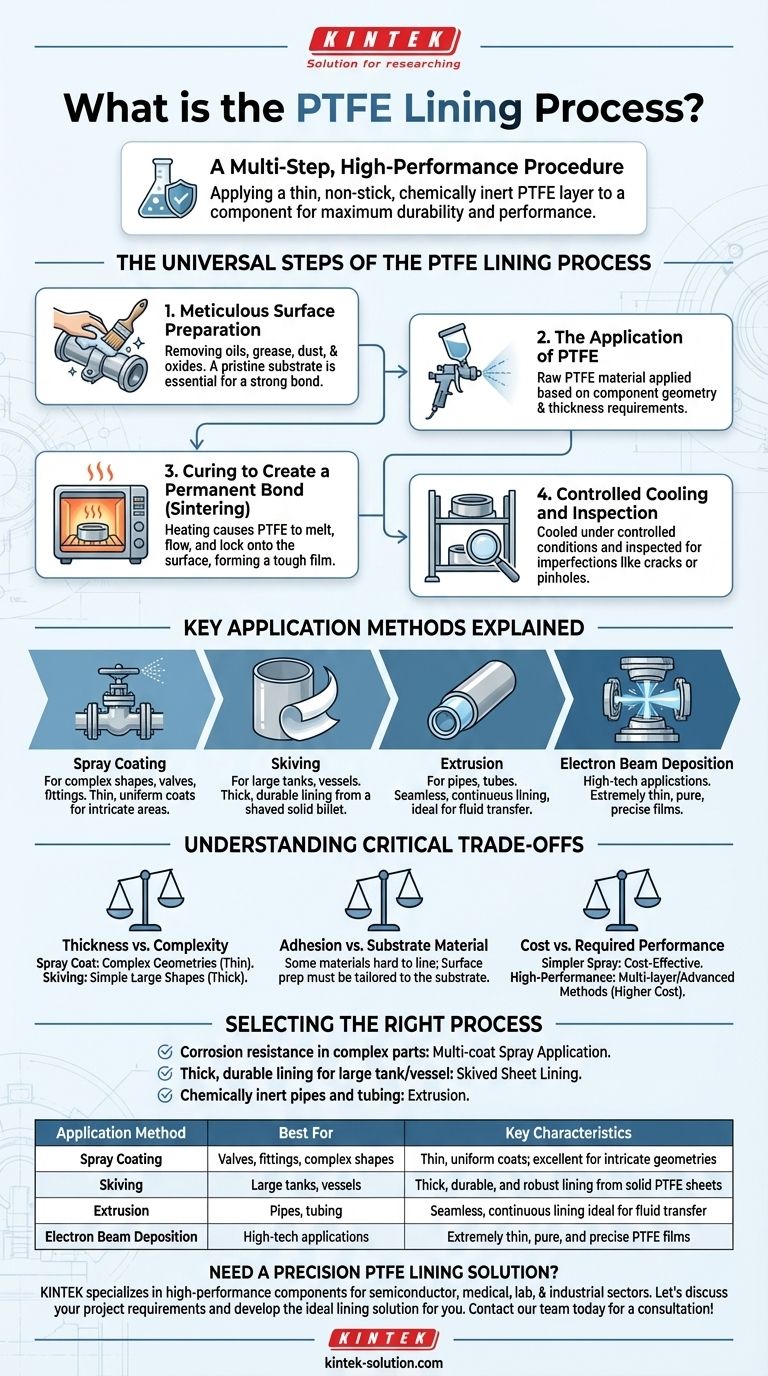

The Universal Steps of the PTFE Lining Process

While application methods vary, every successful PTFE lining procedure is built upon a foundation of four critical stages. Each step ensures the final lining has maximum adhesion and performs exactly as specified.

Step 1: Meticulous Surface Preparation

Before any PTFE is applied, the base material, or substrate, must be perfectly clean. This involves removing all oils, grease, dust, and oxides. A pristine surface is non-negotiable, as it is essential for creating a strong mechanical bond between the substrate and the PTFE lining.

Step 2: The Application of PTFE

This is where the raw PTFE material is applied to the prepared surface. The specific method used here is the most variable part of the process and is chosen based on the geometry of the part and the required thickness of the lining.

Step 3: Curing to Create a Permanent Bond

After application, the component is heated in a controlled oven. This critical heating step, often called sintering, causes the PTFE particles to melt, flow together, and lock onto the prepared surface as they form a tough, non-porous film.

Step 4: Controlled Cooling and Inspection

The component is allowed to cool and harden under controlled conditions to prevent stress or defects in the lining. Finally, the finished lining is inspected for any imperfections, such as cracks, pinholes, or inconsistencies in thickness, to ensure it meets quality standards.

Key Application Methods Explained

The "application" step can be accomplished in several ways, each suited to different types of components. The method directly influences the lining's characteristics.

Spray Coating

For components with complex shapes, like valves or fittings, liquid dispersions of PTFE are sprayed onto the surface. This method allows for thin, uniform coats that can reach intricate and hard-to-reach areas. Often, multiple layers are applied to achieve the desired thickness and performance.

Skiving

Skiving involves creating a thin sheet of PTFE by "shaving" it from a large, solid billet of material. This sheet is then fitted and bonded to the interior of simpler shapes, like large tanks or vessels. This method produces a thick, durable, and uniform lining.

Extrusion

This process is ideal for creating lined pipes and tubes. A tube of PTFE is extruded and then inserted into a metal pipe, where it is flared over the ends to create a seamless, continuous lining. It provides a consistent thickness perfect for fluid transfer applications.

Electron Beam Deposition

A more advanced and specialized technique, electron beam deposition is a physical vapor deposition method. It is used in high-tech applications to create extremely thin, pure, and precise PTFE films on various substrates.

Understanding the Critical Trade-offs

Choosing a PTFE lining process is not just about performance; it involves balancing competing factors. Understanding these trade-offs is crucial for making an informed decision.

Thickness vs. Complexity

Spray coating excels at covering complex geometries but typically results in a thinner lining. In contrast, skived sheets provide a much thicker and more robust barrier but are only suitable for simple, large-surface-area components.

Adhesion vs. Substrate Material

The ultimate success of any lining process hinges on the bond to the substrate. Some materials are inherently more difficult to line than others. The surface preparation step must be tailored specifically to the substrate material to guarantee proper adhesion.

Cost vs. Required Performance

Simpler, single-coat spray applications are generally the most cost-effective. However, high-performance applications demanding extreme chemical resistance or durability may require thicker, multi-layer systems, skived sheets, or more advanced methods, which significantly increase costs.

Selecting the Right Process for Your Application

Your final choice depends entirely on the goal you need to achieve. By matching the method to the need, you ensure optimal performance and cost-efficiency.

- If your primary focus is corrosion resistance in complex parts: A multi-coat spray application is the most versatile and effective solution.

- If your primary focus is a thick, durable lining for a large tank or vessel: A skived sheet lining provides the most robust and uniform protection.

- If your primary focus is creating chemically inert pipes and tubing: Extrusion is the standard industrial process designed for this exact purpose.

Ultimately, understanding these core processes empowers you to specify the precise lining solution that meets your project's performance, geometric, and budgetary requirements.

Summary Table:

| Application Method | Best For | Key Characteristics |

|---|---|---|

| Spray Coating | Valves, fittings, complex shapes | Thin, uniform coats; excellent for intricate geometries |

| Skiving | Large tanks, vessels | Thick, durable, and robust lining from solid PTFE sheets |

| Extrusion | Pipes, tubing | Seamless, continuous lining ideal for fluid transfer |

| Electron Beam Deposition | High-tech applications | Extremely thin, pure, and precise PTFE films |

Need a Precision PTFE Lining Solution?

KINTEK specializes in manufacturing high-performance PTFE components—including custom-lined seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components achieve maximum chemical resistance, non-stick performance, and durability through our expert application processes, from prototypes to high-volume orders.

Let's discuss your project requirements and develop the ideal lining solution for you. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications