The primary function of a PTFE/silicone septum is to serve as a dual-purpose barrier in an HPLC autosampler vial. It creates a chemically inert and physically secure seal that protects the sample from evaporation and contamination, while also allowing for clean, repeatable piercing by the autosampler needle. This combination is essential for maintaining sample integrity from storage through injection.

The effectiveness of a PTFE/silicone septum is not just in sealing the vial, but in how its two distinct layers work together. The PTFE side provides a chemically non-reactive barrier to the sample, while the silicone side provides the mechanical resealability required for automated, high-precision analysis.

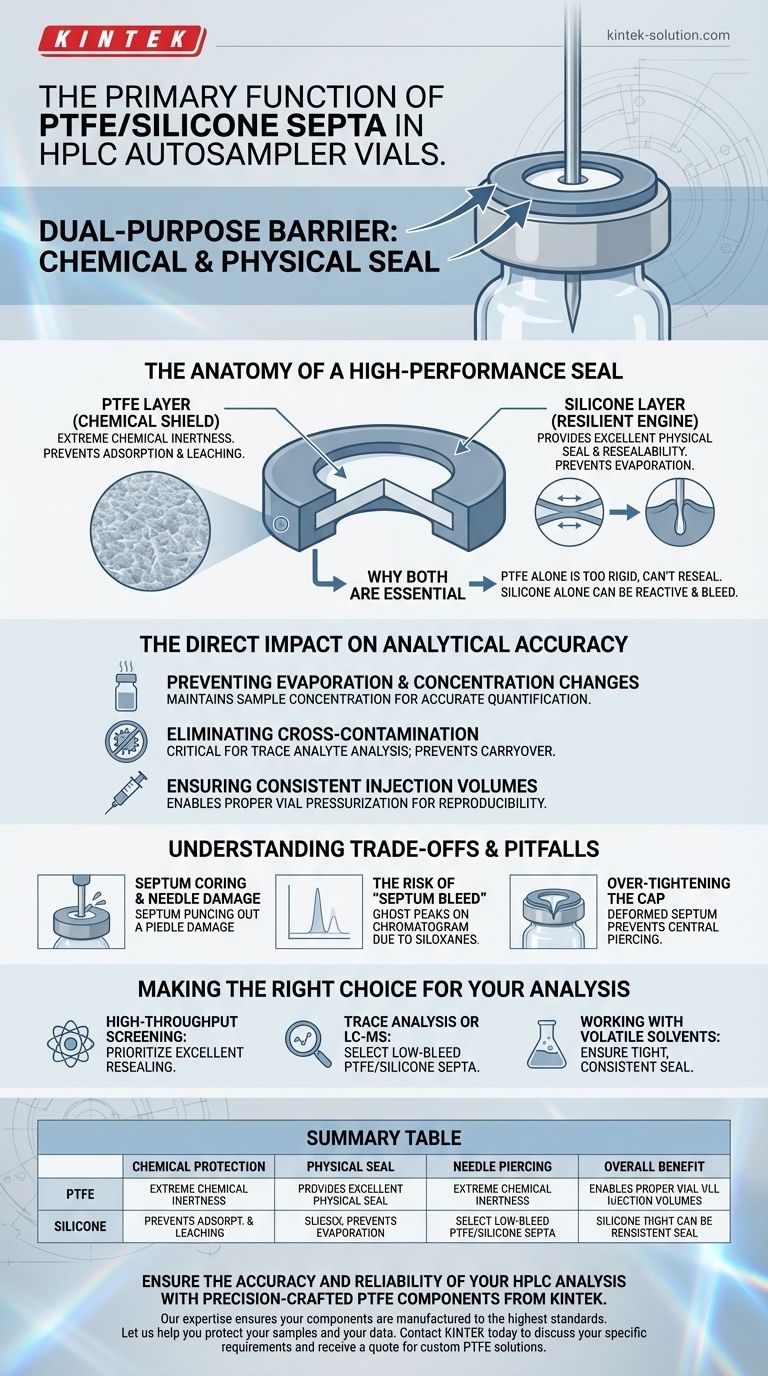

The Anatomy of a High-Performance Seal

An HPLC vial septum is not merely a lid; it is a precision-engineered component critical to analytical success. Its dual-layer construction is designed to solve two different problems simultaneously.

The PTFE Layer: Your Chemical Shield

The layer facing the sample is made of Polytetrafluoroethylene (PTFE), commonly known as Teflon®. This material is chosen for its extreme chemical inertness.

Its primary role is to prevent any interaction between the septum and the sample. This non-stick, non-reactive surface minimizes the risk of analyte adsorption and leaching of contaminants from the septum into your sample.

The Silicone Layer: The Resilient Engine

The thicker, outer layer is made of silicone. This material provides the mechanical properties required for an autosampler environment.

Silicone is soft, elastic, and provides an excellent physical seal against the glass rim of the vial. Its most important feature is its resealability, allowing it to close tightly around the needle hole after the injection needle is withdrawn.

Why Both Layers Are Essential

PTFE alone is too rigid and would not reseal after being punctured, leading to sample evaporation and contamination.

Silicone alone, while providing a great seal, can be chemically reactive with certain organic solvents and is prone to "septum bleed," where small molecules (siloxanes) can leach into the sample, creating ghost peaks in your chromatogram.

The Direct Impact on Analytical Accuracy

A failing septum directly compromises the quality of your data. Understanding its function reveals how it underpins reliable results.

Preventing Evaporation and Concentration Changes

The most basic function of the seal is to prevent the loss of volatile solvents. Even a small leak can significantly change the concentration of your sample over the course of a long analytical run, leading to inaccurate quantification.

Eliminating Cross-Contamination

The inert PTFE layer ensures that molecules from a previous sample do not adhere to the septum and get carried into the next. This is especially critical for trace analyte analysis, where even minute carryover can invalidate results.

Ensuring Consistent Injection Volumes

A properly sealed vial allows the autosampler to function correctly. A poor seal can affect vial pressurization, leading to inconsistent sample draw and variable injection volumes, which directly harms the precision and reproducibility of your measurements.

Understanding the Trade-offs and Common Pitfalls

While PTFE/silicone septa are the industry standard, improper use or selection can still lead to problems.

Septum Coring and Needle Damage

Coring occurs when the needle punches a piece of the septum out instead of piercing it cleanly. This fragment contaminates the sample and destroys the seal. Using the correct needle style (e.g., a pointed tip) and not over-tightening the cap can mitigate this.

The Risk of 'Septum Bleed'

Not all septa are created equal. Lower-quality silicone can release siloxanes, especially at higher temperatures. For sensitive analyses like mass spectrometry (LC-MS), it is critical to use high-purity, low-bleed septa to ensure a clean background signal.

Over-tightening the Cap

A common mistake is to over-tighten the vial cap. This can deform the septum, causing it to bulge and preventing the needle from piercing it centrally. This deformation also compromises its ability to reseal पत्थर, leading to leaks.

Making the Right Choice for Your Analysis

The ideal septum choice depends on the specific demands of your analytical method.

- If your primary focus is high-throughput screening: Prioritize septa with excellent resealing properties to withstand numerous punctures without compromising the seal.

- If your primary focus is trace analysis or mass spectrometry: Select certified low-bleed PTFE/silicone septa to minimize the risk of background contamination and ensure a clean baseline.

- If your primary focus is working with volatile solvents: Ensure the septum provides a tight, consistent seal to prevent solvent evaporation and sample concentration changes over time.

Ultimately, selecting the correct septum is a critical decision that safeguards the integrity of your entire analytical workflow.

Summary Table:

| Function | PTFE Layer Role | Silicone Layer Role |

|---|---|---|

| Chemical Protection | Prevents analyte adsorption and leaching; chemically inert. | - |

| Physical Seal | - | Creates a tight, elastic seal against the vial rim. |

| Needle Piercing | Provides a clean, non-stick surface for the needle. | Allows for clean puncture and reliable resealing. |

| Overall Benefit | Protects sample integrity. | Enables automated, high-precision analysis. |

Ensure the accuracy and reliability of your HPLC analysis with precision-crafted PTFE components from KINTEK.

Your target application—whether in the semiconductor, medical, laboratory, or industrial sector—demands components that guarantee performance. The critical role of a PTFE/silicone septum, as detailed above, underscores the importance of material quality and manufacturing precision.

KINTEK specializes in the custom fabrication of high-performance PTFE seals, liners, and labware. We understand that your success depends on minimizing contamination, preventing leaks, and achieving consistent results. Our expertise ensures your components are manufactured to the highest standards, from prototype development to high-volume production.

Let us help you protect your samples and your data. Contact KINTEK today to discuss your specific requirements and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability