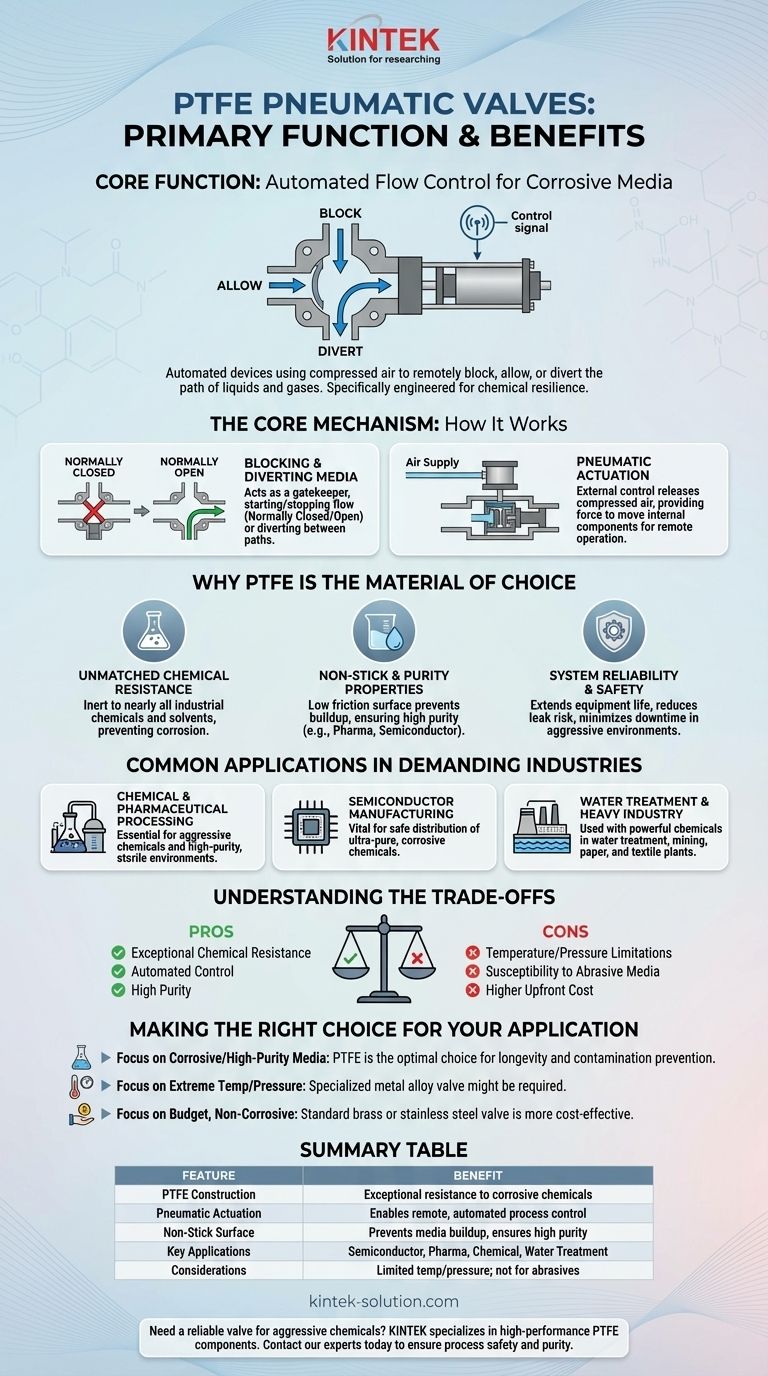

At their core, PTFE pneumatic valves are automated devices designed to control the flow of media within a system. Their primary function is to block, allow, or divert the path of liquids and gases. Unlike manual valves, they are actuated remotely using compressed air, enabling automated and precise process control.

The defining purpose of a PTFE pneumatic valve isn't just its automated control, but its exceptional chemical resilience. It is specifically engineered to provide reliable, automated flow control for highly corrosive or aggressive media that would quickly degrade standard valves.

The Core Mechanism: How It Works

A PTFE pneumatic valve combines a simple mechanical function with a robust material to solve a difficult industrial problem. Understanding both aspects is key to appreciating its value.

Blocking and Diverting Media

The fundamental job of the valve is to act as a gatekeeper in a pipeline. In its simplest form, it is either normally closed (opening only when air pressure is applied) or normally open (closing when air pressure is applied), effectively starting or stopping flow. More complex designs can also divert media between different paths.

Pneumatic Actuation

The "pneumatic" aspect refers to its method of operation. An external control system sends a signal that releases compressed air into an actuator on the valve. This air pressure provides the force to move the internal valve components, opening or closing the flow path without requiring any manual intervention at the valve's location.

Why PTFE is the Material of Choice

The true value of these valves comes from the use of Polytetrafluoroethylene (PTFE), a fluoropolymer known for its unique properties. The valve's internal surfaces, which are exposed to the media, are lined or constructed entirely from PTFE.

Unmatched Chemical Resistance

PTFE is inert to nearly all industrial chemicals and solvents. This exceptional resistance prevents the valve from corroding or being damaged by harsh substances, from strong acids to caustic bases. This is its primary advantage over metal valves.

Non-Stick and Purity Properties

The material has an extremely low coefficient of friction, creating a non-stick surface. This prevents media from building up inside the valve, which is critical for maintaining purity in applications like pharmaceutical production and semiconductor manufacturing.

System Reliability and Safety

By resisting chemical attack, PTFE valves ensure system integrity and safety. They reduce the risk of leaks caused by corrosion, extend the operational life of the equipment, and minimize costly downtime for maintenance and replacement in aggressive environments.

Common Applications in Demanding Industries

PTFE pneumatic valves are specified for applications where material compatibility is a non-negotiable requirement for safety and performance.

Chemical and Pharmaceutical Processing

In facilities handling a wide range of aggressive chemicals or requiring high-purity, sterile environments, PTFE is essential. It ensures that neither the valve is damaged nor the process media is contaminated.

Semiconductor Manufacturing

The production of microchips involves the use of extremely corrosive and ultra-pure chemicals. PTFE pneumatic valves are vital for distributing these chemicals safely and without introducing contaminants that could ruin sensitive electronic components.

Water Treatment and Heavy Industry

Municipal and industrial water treatment facilities often use powerful chemicals like chlorine or sulfuric acid. PTFE valves are also used in mining, paper mills, and textile plants where corrosive substances are part of the process.

Understanding the Trade-offs

While highly effective, PTFE pneumatic valves are a specialized solution with specific limitations that must be considered.

Temperature and Pressure Limitations

Compared to solid metal valves, PTFE has a more limited operating range for temperature and pressure. High-temperature or high-pressure applications can cause the material to deform, so it is critical to operate within the manufacturer's specified limits.

Susceptibility to Abrasive Media

While PTFE's non-stick surface handles many materials well, it is a relatively soft polymer. It is not ideal for controlling the flow of heavy, abrasive slurries that can physically wear away the lining over time.

Higher Upfront Cost

Specialized materials and construction mean these valves typically have a higher initial purchase price than standard stainless steel or brass alternatives. However, this cost is often justified by a lower total cost of ownership due to superior longevity and reduced maintenance in corrosive applications.

Making the Right Choice for Your Application

Choosing the correct valve requires matching its capabilities to your primary operational goal.

- If your primary focus is handling corrosive or high-purity media: A PTFE pneumatic valve is the optimal choice for ensuring system longevity and preventing contamination.

- If your primary focus is extreme temperature or pressure service: You must carefully check the valve's specifications, as a specialized metal alloy valve may be required.

- If your primary focus is budget on a non-corrosive system: A standard pneumatic valve made from brass or stainless steel will likely provide the necessary function more cost-effectively.

Ultimately, selecting a PTFE pneumatic valve is a strategic decision to ensure safety, reliability, and purity in chemically demanding environments.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Construction | Exceptional resistance to corrosive chemicals and solvents |

| Pneumatic Actuation | Enables remote, automated process control |

| Non-Stick Surface | Prevents media buildup and ensures high purity |

| Key Applications | Semiconductor manufacturing, Pharmaceutical processing, Chemical handling, Water treatment |

| Considerations | Limited temperature/pressure range vs. metal; not ideal for abrasive slurries |

Need a reliable valve for aggressive chemicals? KINTEK specializes in manufacturing high-performance PTFE components, including pneumatic valves, seals, and labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a solution perfectly tailored to handle your most demanding corrosive media in semiconductor, medical, laboratory, and industrial settings. Contact our experts today to discuss your specific requirements and ensure process safety and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are PTFE expansion joints and what is their primary function? Protect Your Piping System from Stress and Failure

- What role do PTFE gaskets play in the energy and power industry? Ensuring Safety and Reliability in Critical Infrastructure

- What factors affect the lifespan of PTFE tubing and rods? Ensure Long-Term Reliability for Your Critical Applications

- What are the benefits of PTFE sealed ball bearings? Achieve Peak Performance with Low Friction & Zero Maintenance

- How is Teflon coating applied in the construction industry? Enhancing Safety and Durability in Building Components

- Why is compatibility with equipment crucial when selecting PTFE packing? Avoid Costly Failures & Downtime

- How do PTFE-lined valves compare to traditional metallic valves? Maximize Performance in Corrosive Applications

- When are split PTFE backup rings particularly suitable? Ideal for Retrofitting and High-Pressure Seals