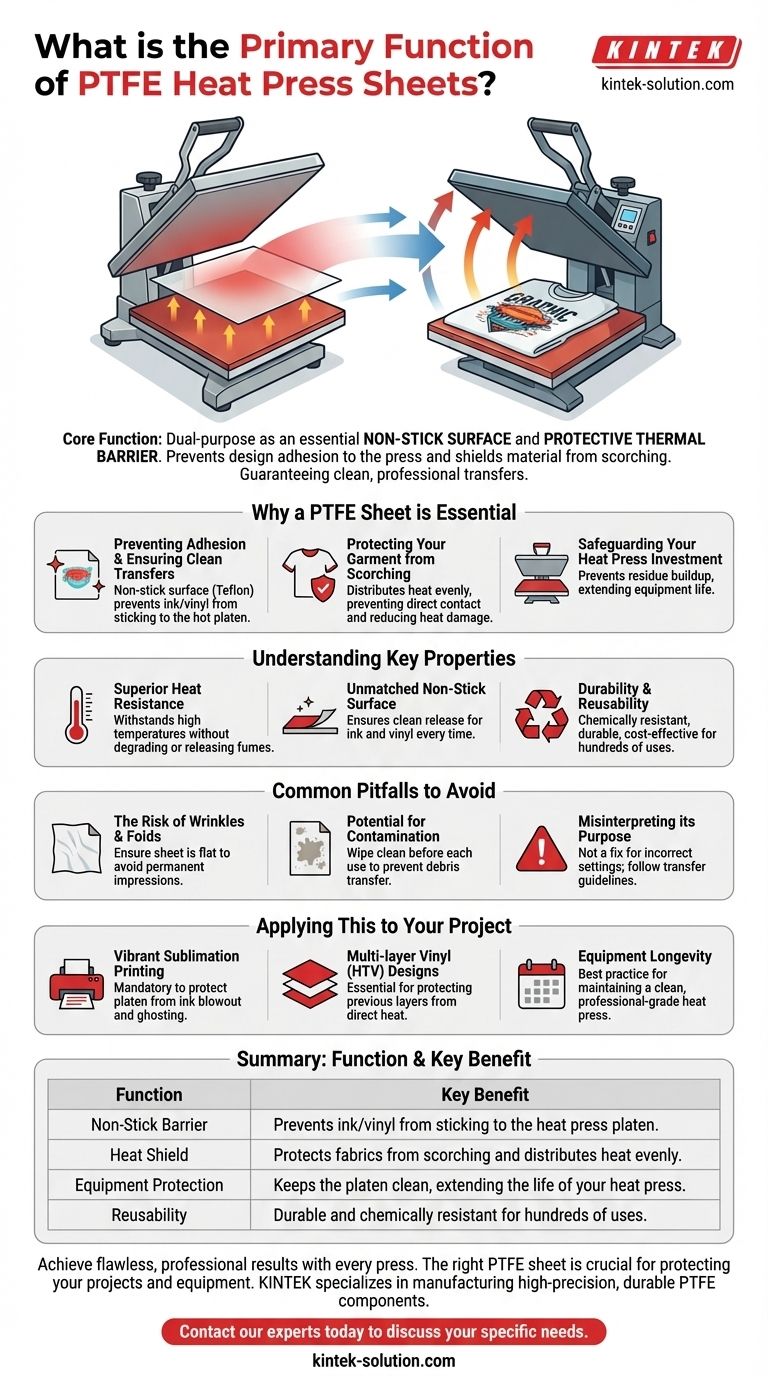

At its core, a PTFE heat press sheet serves a dual function as an essential non-stick surface and a protective thermal barrier. It is placed between your heat press platen and your transfer design to prevent the design from adhering to the hot press while simultaneously shielding the underlying material from scorching.

The primary purpose of a PTFE sheet is to guarantee a clean, professional transfer by creating a reusable, heat-resistant, non-stick barrier that protects both your project and your equipment from damage.

Why a PTFE Sheet is Essential for Heat Pressing

Understanding the role of this sheet moves it from an optional accessory to a non-negotiable component for quality work. Its properties directly solve the most common problems encountered during heat transfer applications.

Preventing Adhesion and Ensuring Clean Transfers

The most critical feature of a PTFE sheet is its non-stick surface. During a press, excess inks from sublimation or adhesives from heat transfer vinyl (HTV) can melt and stick to the hot upper platen of your press.

A PTFE sheet, often known by the brand name Teflon, creates a barrier that prevents this adhesion entirely. This ensures your design remains crisp and your platen stays clean for the next job.

Protecting Your Garment from Scorching

Many fabrics, especially synthetics and light-colored materials, are susceptible to scorching or yellowing under intense, direct heat.

The sheet acts as a shield, distributing the heat more evenly across the surface. This buffer prevents direct contact with the metal platen, significantly reducing the risk of heat damage to your garment.

Safeguarding Your Heat Press Investment

Residue from vinyl, ink, and adhesives can build up on your heat press platen over time. This contamination can be difficult to clean and can ruin future projects by transferring old residue onto new garments.

Using a PTFE sheet on every press is the simplest way to keep your equipment's platen in pristine condition, extending its life and ensuring consistent results.

Understanding the Key Properties

The effectiveness of a PTFE sheet comes from a unique combination of material properties that make it perfectly suited for high-temperature applications.

Superior Heat Resistance

These sheets are engineered to withstand the high temperatures required for various heat transfer methods without degrading, melting, or releasing harmful fumes.

Unmatched Non-Stick Surface

This property ensures that no part of your transfer—whether ink or vinyl—will stick to the sheet or the platen. This allows for a clean release every single time.

Durability and Reusability

PTFE is also chemically resistant and durable. A single sheet can be wiped clean and reused for hundreds or even thousands of presses, making it an extremely cost-effective tool.

Common Pitfalls to Avoid

While incredibly useful, a PTFE sheet must be used correctly to be effective. Awareness of common mistakes can prevent frustrating and costly errors.

The Risk of Wrinkles and Folds

Always ensure your PTFE sheet is completely flat and smooth before pressing. Any wrinkles or creases in the sheet can be permanently impressed into your vinyl design, ruining the final product.

Potential for Contamination

Before each use, wipe down the sheet to ensure it is free from dust, lint, or residue from a previous project. A contaminated sheet can transfer unwanted debris onto your new garment.

Misinterpreting its Purpose

A PTFE sheet is a protective tool, not a fix for incorrect settings. It cannot compensate for using the wrong temperature, pressure, or time for your specific material. Always follow the guidelines for your transfer product first.

Applying This to Your Project

Your specific application will determine how you leverage the benefits of a PTFE sheet.

- If your primary focus is vibrant sublimation printing: The sheet is mandatory to protect your platen from ink "blowout" and prevent ghosting in your image.

- If your primary focus is multi-layer vinyl (HTV) designs: The sheet is essential for protecting previously applied vinyl layers from the direct heat of the platen as you add subsequent layers.

- If your primary focus is equipment longevity: Using a sheet for every single press, regardless of the project, is the single best practice for maintaining a clean, professional-grade heat press.

Ultimately, this simple sheet is the key to elevating your results from amateur to professional by ensuring consistency, cleanliness, and protection.

Summary Table:

| Function | Key Benefit |

|---|---|

| Non-Stick Barrier | Prevents ink/vinyl from sticking to the heat press platen. |

| Heat Shield | Protects fabrics from scorching and distributes heat evenly. |

| Equipment Protection | Keeps the platen clean, extending the life of your heat press. |

| Reusability | Durable and chemically resistant for hundreds of uses. |

Achieve flawless, professional results with every press. The right PTFE sheet is crucial for protecting your projects and equipment. KINTEK specializes in manufacturing high-precision, durable PTFE components, including heat press sheets, for the textile, promotional product, and industrial sectors. Whether you need a standard size or a custom-fabricated solution for high-volume orders, our expertise ensures optimal performance and longevity.

Contact our experts today to discuss your specific needs and discover how KINTEK's PTFE solutions can enhance your heat transfer process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications