The primary advantage of a PTFE control valve is its exceptional, near-universal resistance to chemical corrosion. Because all wetted parts—the body, stem, and ball—are constructed from Polytetrafluoroethylene (PTFE), the valve is fundamentally inert, making it the ideal choice for controlling the flow of highly aggressive and corrosive fluids that would destroy traditional metal valves.

The core value of a PTFE valve isn't just that it resists chemicals, but that it effectively ignores them. This chemical indifference ensures process purity, operational safety, and an exceptionally long, maintenance-free service life in the most demanding industrial environments.

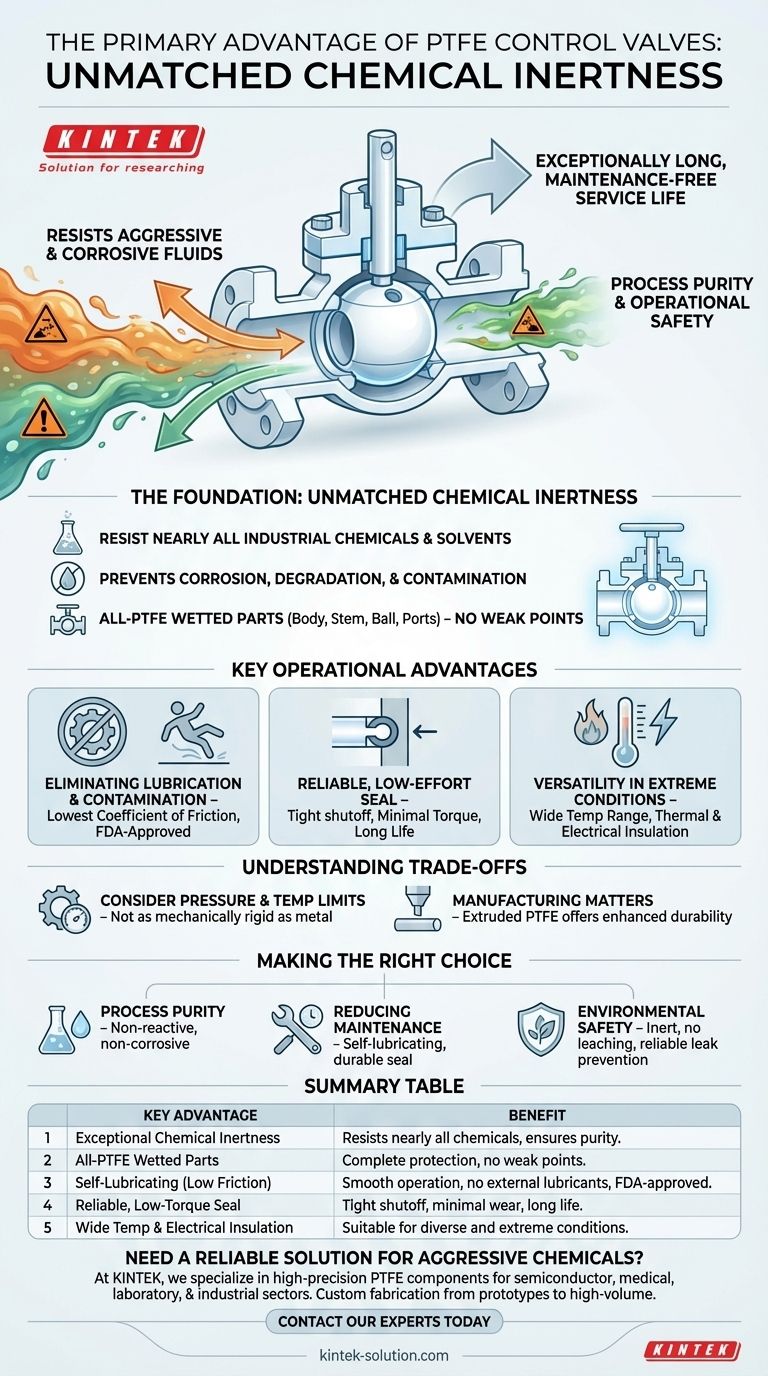

The Foundation: Unmatched Chemical Inertness

The unique properties of PTFE are the source of its performance. Understanding these foundational characteristics explains why it is so effective in specialized applications.

### What "Chemically Inert" Means for Your Process

PTFE is resistant to nearly all industrial chemicals and solvents. This means the valve material does not react with the media flowing through it.

This non-reactive nature prevents the valve itself from corroding, degrading, or leaching contaminants into the process fluid, which is critical for high-purity applications.

### Comprehensive Material Protection

In a true PTFE valve, it's not just a lining. The body, stem, ball, and ports are all constructed from solid PTFE.

This ensures there are no weak points where corrosive media can attack a less-resistant base material, guaranteeing the integrity of the entire assembly.

Key Operational Advantages of PTFE Valves

The benefits of PTFE extend beyond simple corrosion resistance. Its other inherent properties translate directly into superior performance, reliability, and lower operational costs.

### Eliminating Lubrication and Contamination

PTFE has the lowest coefficient of friction of any solid material, often described as the most slippery material known.

This property means the valve operates smoothly without any need for external lubricants, which could otherwise contaminate the process media. This is a primary reason PTFE is FDA-approved for food contact.

### Ensuring a Reliable, Low-Effort Seal

The material's properties allow for a tight seal with minimal torque. This reduces the stress on actuation systems and minimizes wear on the valve components over time.

The result is a valve that provides a reliable, shock-free shutoff and enjoys a long, maintenance-free service life.

### Versatility in Extreme Conditions

PTFE operates effectively across a very wide temperature range, withstanding both extreme heat and cold.

Furthermore, it possesses outstanding thermal and electrical insulation properties. This makes PTFE valves suitable for a diverse range of industrial processes beyond just chemical handling.

Understanding the Trade-offs

While PTFE's advantages are significant, it's critical to select the right type for your application, as not all PTFE is created equal.

### The Importance of Manufacturing Process

The durability of the valve is heavily influenced by how the PTFE components are made.

Extruded PTFE, for example, undergoes a specialized extrusion and sintering process. This strengthens the material's structure, offering enhanced durability and chemical resistance compared to other forms.

### Considering Physical vs. Chemical Demands

PTFE's primary strength is its chemical immunity, not its mechanical rigidity compared to metal.

While perfect for corrosive environments, you must always operate within the manufacturer's specified pressure and temperature limits to ensure structural integrity.

Making the Right Choice for Your Goal

Selecting a PTFE valve is a strategic decision based on solving specific, often difficult, operational challenges.

- If your primary focus is process purity or handling aggressive chemicals: PTFE is the definitive choice due to its non-reactive and non-corrosive nature.

- If your primary focus is reducing long-term maintenance: The self-lubricating properties and durable sealing of PTFE valves lead to significantly lower operational costs over time.

- If your primary focus is environmental safety: PTFE's inertness prevents harmful chemicals from leaching, and its reliable seal minimizes the risk of leaks.

Ultimately, choosing a PTFE valve provides confidence and reliability in applications where other materials would quickly fail.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Exceptional Chemical Inertness | Resists nearly all industrial chemicals and solvents, ensuring process purity and preventing contamination. |

| All-PTFE Wetted Parts | Solid PTFE body, stem, and ball provide complete protection with no weak points for corrosion to attack. |

| Self-Lubricating (Low Friction) | Operates smoothly without external lubricants, eliminating a source of contamination (FDA-approved). |

| Reliable, Low-Torque Seal | Ensures tight shutoff with minimal wear, leading to a long, maintenance-free service life. |

| Wide Temperature Range & Electrical Insulation | Suitable for diverse and extreme process conditions beyond standard chemical handling. |

Need a reliable solution for handling aggressive chemicals?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including control valves, seals, and liners. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a valve that delivers unmatched chemical resistance, process purity, and long-term reliability for your application in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today to discuss your specific requirements and discover how our PTFE valves can solve your most demanding fluid control challenges.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry