At its core, a PTFE machined bellow functions as a flexible, protective connector within an engineered system. Its primary purpose is to absorb unwanted stress—whether mechanical, thermal, or chemical—to prevent damage to critical components, compensate for movement, and ensure system integrity in demanding environments.

The crucial takeaway is that PTFE machined bellows are not just simple flexible joints. They are highly specialized components chosen for their unique ability to provide protection in environments where extreme chemical inertness, high purity, and thermal stability are non-negotiable.

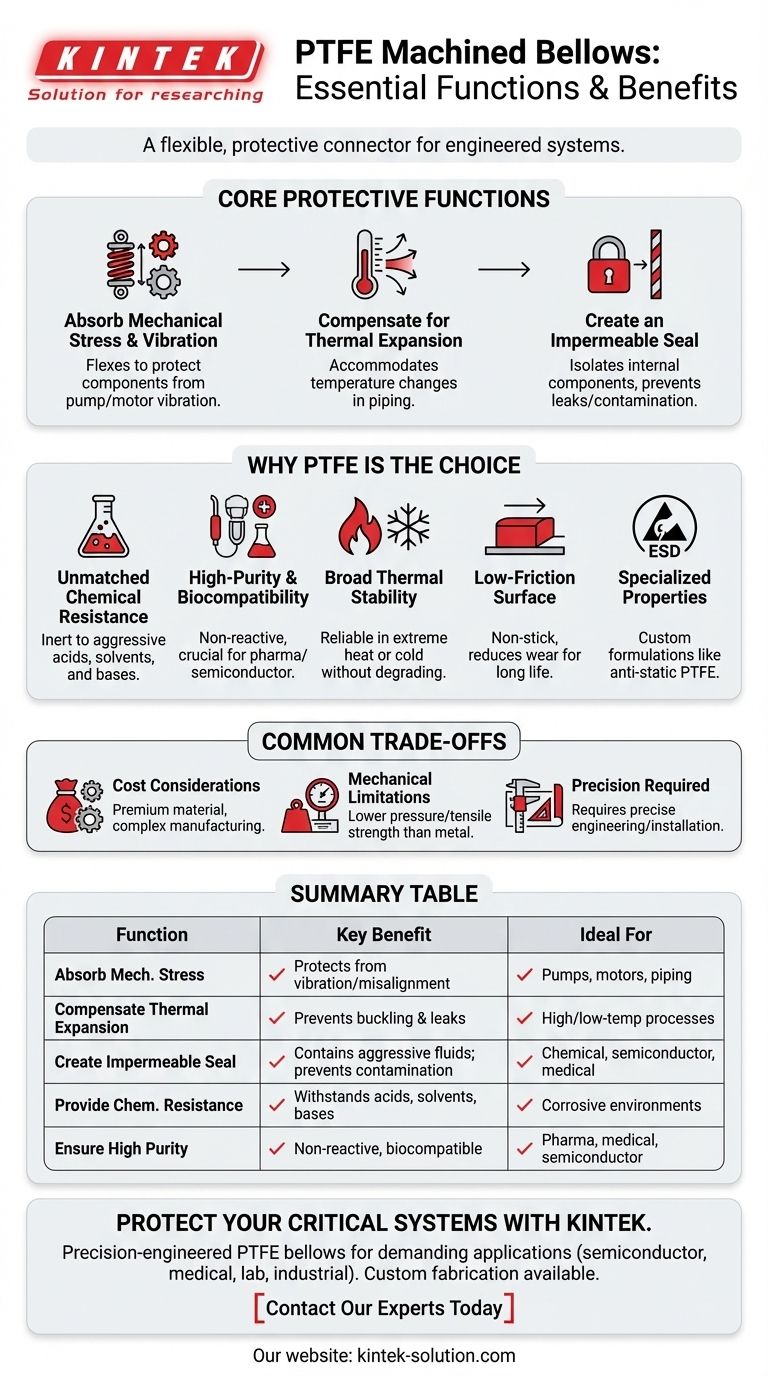

The Core Protective Functions of a Bellow

A bellow acts as a dynamic seal and a flexible joint. It isolates components from harmful forces that could otherwise lead to system failure.

Absorbing Mechanical Stress and Vibration

Bellows are designed to flex and compress, allowing them to absorb vibration from pumps or motors. They also compensate for minor shaft or pipe misalignment, reducing stress on fixed connection points.

Compensating for Thermal Expansion

Materials expand and contract with temperature changes. A PTFE bellow accommodates this thermal movement in piping or ducting systems, preventing buckling, stress fractures, and leaks.

Creating an Impermeable Seal

In many applications, the bellow's most critical job is to create a sealed barrier. This protects internal components from external contaminants or, conversely, contains aggressive process fluids, preventing them from escaping and damaging the surrounding equipment.

Why PTFE is the Material of Choice for Bellows

The unique properties of Polytetrafluoroethylene (PTFE) make it an ideal material for bellows used in the most challenging applications.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals and corrosive agents. This makes it the default choice for systems handling aggressive acids, solvents, and bases in the chemical, petrochemical, and pharmaceutical industries.

High-Purity and Biocompatibility

Because PTFE is non-reactive and does not leach contaminants, it is essential for high-purity applications. This is critical in semiconductor manufacturing, where even trace impurities can ruin a process, and in medical devices like ventilators, where biocompatibility is required for patient safety.

Broad Thermal Stability

PTFE maintains its properties across a wide operating temperature range. This allows PTFE bellows to perform reliably in systems that experience extreme heat or cold without becoming brittle or degrading.

Low-Friction Surface

The material's exceptionally low coefficient of friction (non-stick) prevents material from building up on its surface and reduces wear from repeated flexing, contributing to a long and low-maintenance service life.

Specialized Properties

PTFE can be formulated for specific needs. For example, anti-static PTFE is used in electronics manufacturing where static discharge could damage sensitive components.

Common Pitfalls and Trade-offs

While highly effective, PTFE bellows are a specialized solution. Understanding their limitations is key to successful implementation.

Cost Considerations

Machined PTFE is a premium material, and the manufacturing process is more complex than for molded rubber or metal alternatives. This results in a higher initial component cost, which must be weighed against the long-term benefits of reliability and reduced maintenance.

Mechanical Limitations

Compared to metal bellows, PTFE has a lower tensile strength and pressure rating. In applications involving very high internal pressures or significant physical loads, a metal bellow might be a more suitable, though less chemically resistant, choice.

Precision is Required

The benefits of a "machined" bellow—namely dimensional accuracy—are only realized with precise engineering and installation. Improper sizing or installation can negate the bellow's protective qualities and lead to premature failure.

Making the Right Choice for Your Application

Selecting the right component depends entirely on the primary demands of your system.

- If your primary focus is maximum purity and biocompatibility: PTFE is the definitive choice for medical devices, pharmaceutical processing, or semiconductor manufacturing.

- If your primary focus is handling aggressive chemicals and corrosion: The near-total chemical inertness of PTFE makes it the safest and most reliable option for chemical processing lines and valves.

- If your primary focus is compensating for vibration and thermal expansion in a clean environment: PTFE bellows provide a durable, low-maintenance solution without the risk of contamination from lubricants or material degradation.

Ultimately, choosing a PTFE machined bellow is a decision to prioritize system integrity and longevity in environments where other materials would quickly fail.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Absorb Mechanical Stress | Protects components from vibration/misalignment | Pumps, motors, piping systems |

| Compensate for Thermal Expansion | Prevents buckling and leaks | High/low-temperature processes |

| Create an Impermeable Seal | Contains aggressive fluids; prevents contamination | Chemical, semiconductor, medical industries |

| Provide Chemical Resistance | Withstands acids, solvents, and bases | Corrosive environments |

| Ensure High Purity | Non-reactive, biocompatible surface | Pharma, medical, semiconductor manufacturing |

Protect your critical systems with precision-engineered PTFE bellows from KINTEK.

Our machined PTFE components—including seals, liners, and bellows—are designed for the most demanding applications in semiconductor, medical, laboratory, and industrial settings. We prioritize precision manufacturing and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss your project requirements and ensure unmatched system integrity and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability