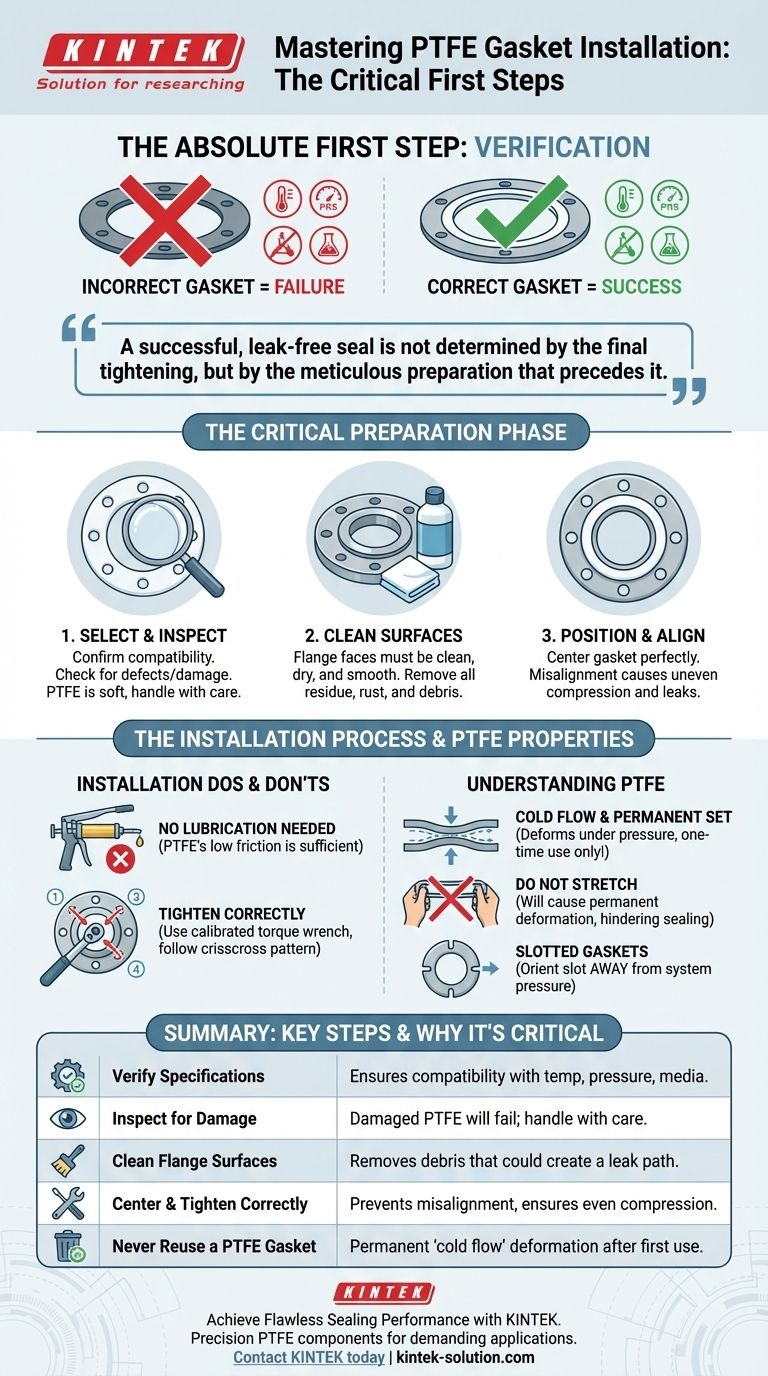

Before you touch a single bolt, the first step in installing a PTFE gasket is to verify you have the correct one for the job. This involves confirming that the gasket's size, type, and material specifications match the equipment model and the service conditions, such as temperature, pressure, and the chemical media it will contact.

A successful, leak-free seal is not determined by the final tightening of the bolts, but by the meticulous preparation that precedes it. The process is less about force and more about precision, cleanliness, and using the right component from the very beginning.

The Critical Preparation Phase

Proper installation begins long before the gasket is placed on the flange. Overlooking these initial steps is the most common source of seal failure.

Selecting the Correct Gasket

The absolute first action is to confirm component compatibility. A gasket that is incorrect for the application is guaranteed to fail, regardless of how well it is installed. Ensure the chosen PTFE gasket is rated for the system's operational pressure and temperature and is chemically compatible with the fluid or gas being sealed.

Inspecting the Gasket for Defects

Once you have the correct gasket, handle it carefully and inspect it for any damage. Look for nicks, scratches, or any imperfections from manufacturing or storage. PTFE is a relatively soft material and can be easily damaged, compromising its sealing ability.

Preparing the Sealing Surfaces

The flange faces must be perfectly clean, dry, and smooth. Remove all old gasket material, rust, or other debris. Even minor surface imperfections or leftover residue can create a leak path. Ensure there are no burrs or sharp edges on the equipment that could damage the new gasket during installation.

The Installation Process Explained

With the preparation complete, the focus shifts to precise physical installation. Each step requires careful attention to detail.

Positioning and Alignment

Carefully place the gasket on the flange face, ensuring it is perfectly centered between the bolt holes. Misalignment is a primary cause of leaks and gasket damage, as it leads to uneven compression when the bolts are tightened.

The Myth of Lubrication

Unlike many other gasket materials, PTFE gaskets should not be greased. The material's naturally low coefficient of friction allows for smooth placement and compression without any additional lubricants, which can interfere with the sealing mechanism.

Proper Bolt Tightening

Tighten the bolts or studs in a staggered, crisscross pattern to apply pressure evenly across the flange. It is critical to use a calibrated torque wrench and follow the manufacturer's recommended torque values. Both under-tightening and over-tightening can cause the seal to fail.

Understanding PTFE's Unique Properties

PTFE is an excellent sealing material, but its unique characteristics demand specific handling procedures. Ignoring them will lead to problems.

The Reality of "Cold Flow"

PTFE exhibits a property called cold flow, where the material slowly deforms under sustained pressure. This is why PTFE gaskets take a permanent impression of the flange surface. Because of this, they are strictly one-time use only. Never attempt to reinstall a used PTFE gasket.

Handling and Manipulation

A PTFE gasket must never be stretched or forced into position. Its low elasticity means that any stretching will permanently deform the gasket and prevent it from sealing correctly. For closed grooves or difficult-to-reach areas, use specialized installation aids.

Considerations for Slotted Gaskets

If you are using a slotted or split-type PTFE gasket, its orientation is critical. The slot is designed to compensate for the material's low elasticity but must be positioned correctly. Always orient the slot so that it faces away from the direction of system pressure.

Making the Right Choice for Your Goal

Your approach to installation depends on your primary objective.

- If your primary focus is maximizing seal reliability: Prioritize the cleanliness and condition of the flange surfaces above all else.

- If your primary focus is avoiding common installation errors: Use a calibrated torque wrench and strictly adhere to the recommended crisscross tightening pattern.

- If your primary focus is ensuring long-term performance: Never reuse a PTFE gasket, as its "cold flow" property means it has permanently deformed from its first use.

Ultimately, a successful PTFE gasket installation is a direct result of discipline and precision from start to finish.

Summary Table:

| Key Step | Why It's Critical |

|---|---|

| Verify Gasket Specifications | Ensures compatibility with temperature, pressure, and chemical media. |

| Inspect for Damage | A damaged PTFE gasket will fail; handle with care. |

| Clean Flange Surfaces | Removes debris that could create a leak path. |

| Center Gasket & Tighten Correctly | Prevents misalignment and ensures even compression. |

| Never Reuse a PTFE Gasket | PTFE 'cold flows,' permanently deforming after first use. |

Achieve Flawless Sealing Performance with KINTEK

A successful PTFE gasket installation hinges on precision and the right component. KINTEK manufactures high-performance PTFE seals, liners, and custom labware designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to ensure a perfect fit and reliable performance, from custom prototypes to high-volume orders.

Let us provide the precision PTFE components your application requires.

Contact KINTEK today to discuss your specific needs and ensure a leak-free seal from the very start.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE expansion bellows contribute to pollution control systems? Enhance System Integrity & Safety

- Are PTFE flange gaskets customizable? Tailor Your Sealing Solution for Peak Performance

- Why is virgin PTFE particularly suitable for food and medical applications? Ensuring Purity and Safety

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation

- What are the disadvantages of PTFE lined butterfly valves? Understanding Key Operational Limits

- How is chemical resistance for Teflon encapsulated O-rings measured? Use the 1-10 Scale for Reliable Sealing

- What does the machining process for PTFE parts involve? Mastering Precision for Soft, Heat-Sensitive Materials

- How should PTFE laminated bearing pads be installed? A Guide to Precision Installation for Bridge Movement