At its core, graphite packing is a braided sealing material constructed from high-purity, inorganic carbon yarns. These filaments are twisted together and then woven into a dense, flexible cord. While the primary component is pure carbon, it is often blended or impregnated with other materials like PTFE (Polytetrafluoroethylene) or specialized agents to enhance its performance in specific industrial applications.

The true value of graphite packing lies not just in its carbon composition, but in its braided structure. This design creates a unique combination of high thermal conductivity, low friction, and mechanical strength, making it an indispensable material for sealing demanding high-pressure and high-temperature equipment.

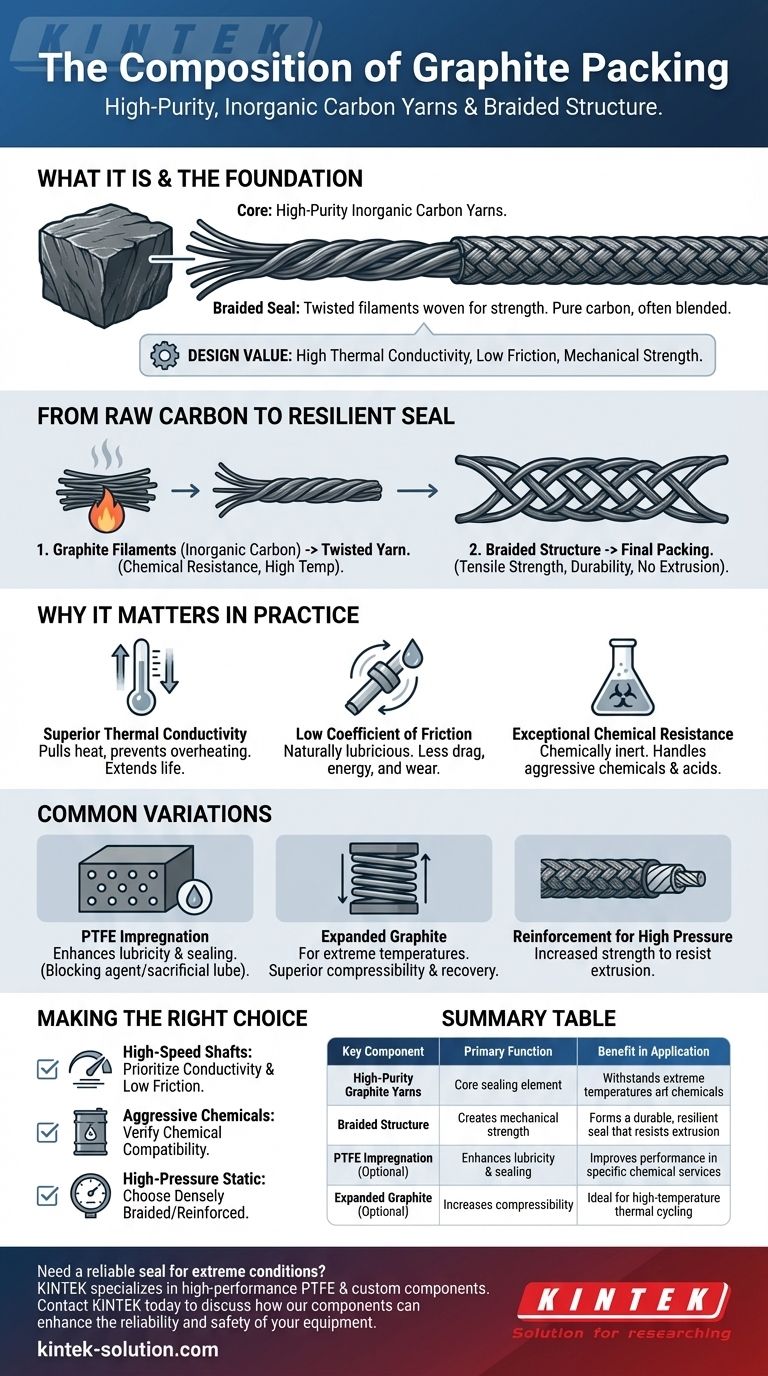

From Raw Carbon to a Resilient Seal

To understand why graphite packing is so effective, we must look at how its composition and structure create its signature properties. It is a multi-step process designed to maximize durability and performance.

The Foundation: High-Purity Graphite Yarns

The process begins with graphite filaments, which are a pure, inorganic form of carbon. These filaments are the fundamental building blocks of the packing. Their inherent carbon nature is what gives the final product its excellent chemical resistance and ability to withstand high temperatures.

The Braiding Process: Building Strength and Durability

Multiple graphite filaments are heated and twisted together to form a single, continuous yarn. This yarn is then braided, often in a complex lattice pattern, to create the final packing material. This braiding process is critical, as it dramatically increases the packing's tensile strength and resilience, allowing it to form a tight, durable seal without extruding under pressure.

Why This Composition Matters in Practice

The specific way graphite packing is made directly translates to its performance in challenging industrial environments, such as in pumps, valves, and agitators.

Superior Thermal Conductivity

The crystalline structure of graphite is exceptionally efficient at conducting heat. In practice, this means the packing can pull damaging heat away from a rotating shaft and dissipate it through the equipment housing. This prevents overheating, reduces wear, and extends the service life of both the packing and the shaft.

Low Coefficient of Friction

Graphite is naturally lubricious, resulting in a very low coefficient of friction. For rotating equipment like pumps and mixers, this means less drag on the shaft. This reduces operational energy costs and minimizes the wear and scoring that can occur with less forgiving materials.

Exceptional Chemical Resistance

As a nearly pure carbon material, graphite is chemically inert to a wide range of substances. This makes it a default choice for sealing equipment that handles aggressive chemicals, acids, caustics, and other harsh media that would quickly degrade other types of packing.

Understanding Common Variations

Not all graphite packing is the same. The base composition is often modified with additives to tailor its performance for specific applications.

The Role of PTFE Impregnation

PTFE is sometimes used to impregnate the graphite yarns before braiding. This can serve as a blocking agent to reduce gas permeability or as a sacrificial lubricant during the initial break-in period. This variation is often used to improve sealing performance in specific chemical services.

Expanded Graphite for Extreme Temperatures

For very high-temperature applications like steam turbines and high-pressure steam valves, a special form called expanded graphite is used. This material offers superior compressibility and recovery, allowing it to maintain a tight seal despite extreme thermal cycling.

Reinforcement for High Pressure

In some cases, the graphite yarns may be reinforced with other materials to increase their strength and resistance to extrusion under extremely high pressures. This ensures the seal remains intact in the most demanding static sealing applications, such as high-pressure block valves.

Making the Right Choice for Your Application

Selecting the correct packing composition is critical for ensuring operational reliability and safety.

- If your primary focus is high-speed rotating shafts: Prioritize a packing with high thermal conductivity and low friction to manage heat and prevent shaft wear.

- If your primary focus is sealing aggressive chemicals: Select a high-purity graphite packing and verify its chemical compatibility with the specific media being handled.

- If your primary focus is high-pressure static sealing: Look for a densely braided packing, potentially with blocking agents or reinforcement, to prevent leakage under extreme force.

By understanding the composition, you can confidently match the material to the unique mechanical and chemical demands of your equipment.

Summary Table:

| Key Component | Primary Function | Benefit in Application |

|---|---|---|

| High-Purity Graphite Yarns | Core sealing element | Withstands extreme temperatures and resists chemicals |

| Braided Structure | Creates mechanical strength | Forms a durable, resilient seal that resists extrusion |

| PTFE Impregnation (Optional) | Enhances lubricity & sealing | Improves performance in specific chemical services |

| Expanded Graphite (Optional) | Increases compressibility | Ideal for high-temperature thermal cycling |

Need a reliable seal for extreme conditions?

KINTEK specializes in manufacturing high-performance PTFE and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution tailored to your specific pressure, temperature, and chemical requirements.

Contact KINTEK today to discuss how our components can enhance the reliability and safety of your equipment.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance