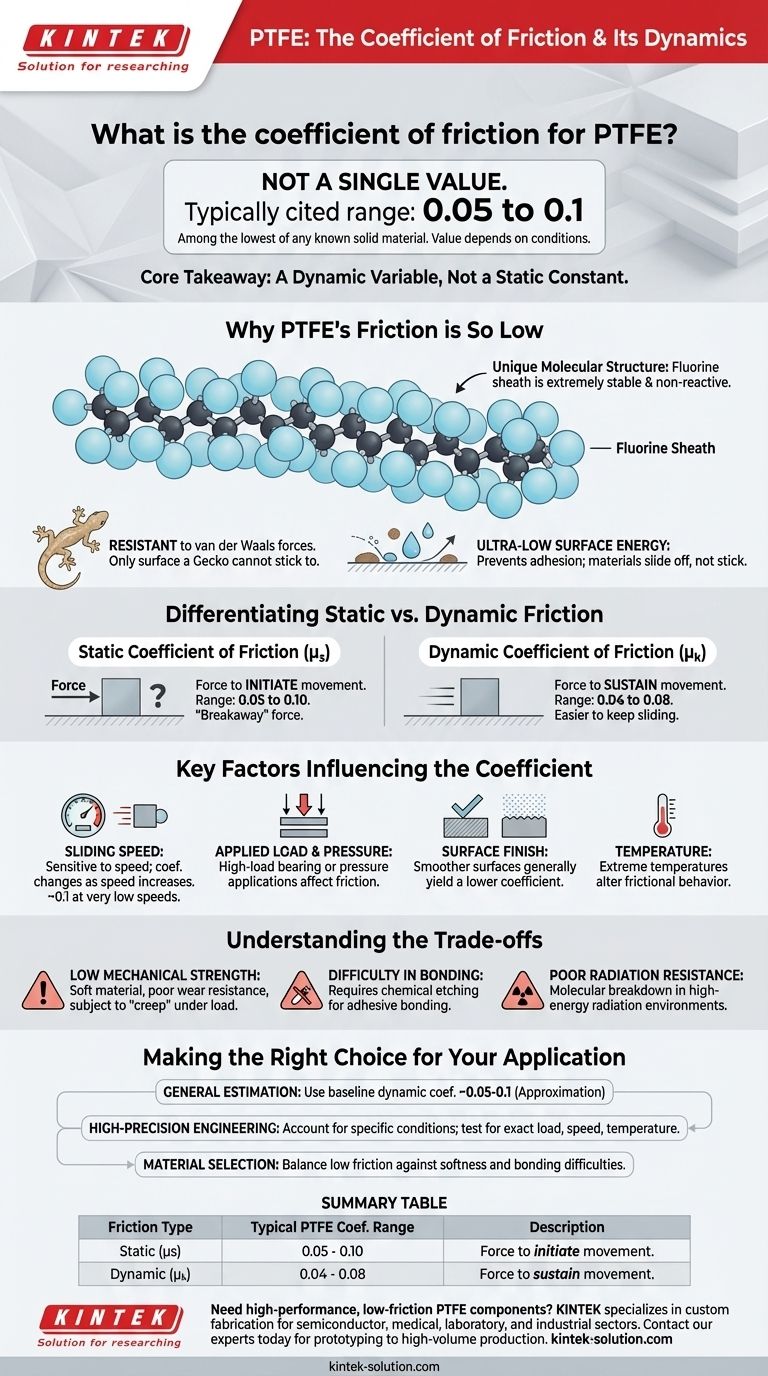

The coefficient of friction for PTFE is not a single value but is typically cited within a range of 0.05 to 0.1. This is one of the lowest friction coefficients of any known solid material. The exact value depends heavily on specific conditions such as whether the object is at rest or in motion, the applied load, and the sliding speed.

The core takeaway is that while PTFE offers exceptionally low friction, its coefficient is a dynamic variable, not a static constant. To use it effectively, you must understand the difference between its static and dynamic coefficients and the real-world factors that influence them.

Why PTFE's Friction is So Low

The remarkably low friction of Polytetrafluoroethylene (PTFE) is not an accident but a direct result of its unique molecular structure and chemistry.

A Unique Molecular Sheath

At a molecular level, PTFE consists of a long chain of carbon atoms completely surrounded by a sheath of fluorine atoms. This fluorine sheath is extremely stable and non-reactive.

Because of this structure, PTFE is highly resistant to the weak intermolecular attractions known as van der Waals forces. This molecular slipperiness is so pronounced that PTFE is the only known surface a Gecko cannot stick to.

Ultra-Low Surface Energy

The chemical inertness of the fluorine sheath gives PTFE an ultra-low surface energy. This means other materials are not attracted to its surface.

This property prevents adhesion, which is a key component of friction. Materials simply slide off rather than "sticking" to the surface, contributing to its famous non-stick characteristic.

Differentiating Static vs. Dynamic Friction

For any engineering application, it is critical to distinguish between the two types of friction coefficients, as they describe different physical states.

Static Coefficient of Friction (μs)

The static coefficient is the force required to initiate movement between two surfaces. For PTFE, this value is generally in the range of 0.05 to 0.10.

This is the number you would use to calculate the "breakaway" force needed to get something to start sliding on a PTFE surface.

Dynamic Coefficient of Friction (μk)

The dynamic (or kinetic) coefficient is the force required to sustain movement once it has already started. This value for PTFE is typically lower, ranging from 0.04 to 0.08.

This lower value explains why it's easier to keep an object sliding than it is to start it moving in the first place.

Key Factors That Influence the Coefficient

The published ranges for PTFE's friction coefficient are baseline values. In any real-world scenario, several factors can alter the effective friction.

Sliding Speed

Friction in PTFE is particularly sensitive to speed. Some data specifies a coefficient of 0.1 at very low speeds (under 10 ft/min). As speed increases, the coefficient can change.

Applied Load and Pressure

The load, or pressure, applied to the PTFE surface can also influence the friction coefficient. These effects must be considered in high-load bearing or high-pressure seal applications.

Surface Finish and Temperature

The roughness of the mating surface and the ambient operating temperature will alter the frictional behavior. A smoother surface will generally yield a lower coefficient, while extreme temperatures can affect the polymer's properties.

Understanding the Trade-offs

PTFE's exceptional low friction comes with practical limitations that are critical for material selection.

Low Mechanical Strength

PTFE is a relatively soft material. It has poor wear resistance and can deform under a sustained load, a phenomenon known as "creep." This makes it unsuitable for high-stress structural applications without reinforcement (e.g., in glass-filled PTFE).

Difficulty in Bonding

The same non-stick properties that lower friction also make PTFE almost impossible to glue. The surface must be chemically etched through a specialized process to allow any adhesive to bond to it.

Poor Radiation Resistance

As a material, PTFE has poor resistance to high-energy radiation, which can break down its molecular structure. This makes it a poor choice for applications in radioactive environments.

Making the Right Choice for Your Application

To apply this knowledge effectively, match your engineering needs to the properties of the material.

- If your primary focus is general estimation: Use a baseline dynamic coefficient of ~0.05 to 0.1 for initial calculations, but recognize this is an approximation.

- If your primary focus is high-precision engineering: Do not rely on a single book value. You must account for the specific static/dynamic conditions and, if possible, test for your application's exact load, speed, and temperature.

- If your primary focus is material selection: Balance PTFE's elite low-friction performance against its mechanical softness and difficulty in bonding to ensure it is suitable for your design.

Ultimately, harnessing the power of PTFE requires acknowledging that its properties are conditional, not absolute.

Summary Table:

| Friction Type | Typical PTFE Coefficient Range | Description |

|---|---|---|

| Static (μs) | 0.05 - 0.10 | Force required to initiate movement. |

| Dynamic (μk) | 0.04 - 0.08 | Force required to sustain movement. |

Need high-performance, low-friction PTFE components for your application?

PTFE's exceptional properties are conditional, and their successful application depends on precision manufacturing and a deep understanding of your specific operating environment.

KINTEK specializes in the custom fabrication of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We help you navigate the trade-offs and deliver solutions that balance low friction with the mechanical performance your design demands.

Let us provide the right PTFE solution for you, from prototype to high-volume production.

Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What industries commonly use PTFE lined butterfly valves? Essential for Corrosive & High-Purity Applications

- Why are PTFE balls preferred for handling corrosive chemicals like hydrochloric acid or sulfuric acid? Ensure Unmatched Chemical Resistance

- What are some common industries and applications for PTFE/Teflon machined parts? Solve Harsh Environment Challenges

- How do the non-stick properties of PTFE oil seals contribute to their performance? Ensure Long-Term Reliability in Harsh Conditions

- What are the common applications of PTFE pneumatic valves? Ensure Purity and Chemical Resistance in Your Process

- What are the key advantages of PTFE rotary shaft seals in automotive use? Boost Performance & Efficiency

- How do expanded PTFE gaskets perform in terms of sealing performance? Achieve Leak-Free Seals on Challenging Surfaces