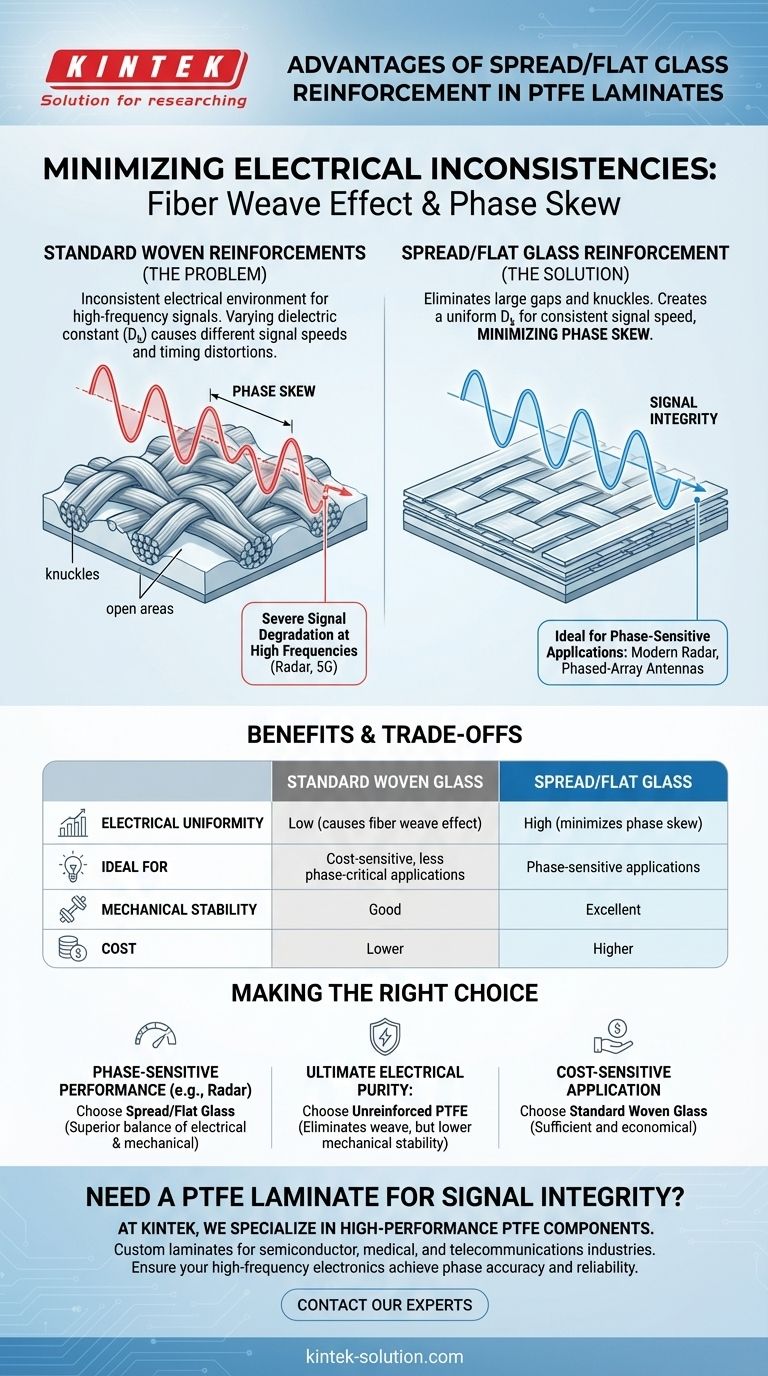

The primary advantage of using spread/flat glass reinforcement in PTFE laminates is its ability to minimize electrical inconsistencies known as the fiber weave effect and phase skew. By creating a more uniform material structure, it ensures that high-frequency signals maintain their timing and integrity as they travel across the circuit board. This makes it the ideal choice for phase-sensitive applications like modern radar systems and phased-array antennas.

The core problem with standard woven reinforcements is that they create an inconsistent electrical environment for high-frequency signals. Spread/flat glass solves this by forming a smoother, more uniform dielectric layer, which is essential for preserving the precise phase relationships that advanced electronics rely on.

The Problem with Standard Woven Reinforcements

To understand the benefit of spread/flat glass, we must first examine the limitations of traditional woven glass fabrics used in many PCB laminates.

The Fiber Weave Effect

A standard woven fabric consists of glass fiber bundles woven in an over-under pattern. This creates "knuckles" where the bundles cross and open areas between them.

Because glass and PTFE have different dielectric constants (Dk), this inconsistent pattern means a signal traveling across the board encounters varying Dk values.

The Consequence: Phase Skew

This variation in dielectric constant causes different parts of a signal to travel at slightly different speeds.

When one part of a signal travels over a glass-rich "knuckle" and another travels over a resin-rich "opening," their timing relationship is distorted. This distortion is known as phase skew.

Why This Matters at High Frequencies

At lower frequencies, these microscopic variations are insignificant. However, at the high frequencies used in radar and 5G communications, signal wavelengths are much shorter.

Even tiny physical inconsistencies in the laminate become a significant fraction of a wavelength, leading to severe signal degradation and performance issues.

How Spread/Flat Glass Solves the Problem

Spread/flat glass reinforcement is specifically engineered to counteract the fiber weave effect and deliver superior electrical performance.

Creating Electrical Uniformity

Instead of using round bundles, the glass fibers are spread into thin, flat, and wide strips before being woven together.

This process effectively eliminates the large gaps and knuckles found in a standard weave, creating a much more homogeneous and uniform material structure.

The Result: A Consistent Dielectric Constant

This uniform structure presents a consistent dielectric constant to a signal trace, regardless of its path across the laminate.

The electrical "road" is smooth and predictable, without the bumps and dips created by a traditional weave.

The Benefit: Preserving Signal Integrity

By providing a consistent Dk, spread/flat glass ensures signals travel at a uniform velocity. This directly minimizes phase skew and preserves the integrity of the signal.

For systems like phased-array antennas that depend on precise timing across many elements, this level of signal fidelity is non-negotiable.

Understanding the Trade-offs

While spread/flat glass offers clear electrical advantages, it's essential to understand its position relative to other material choices.

Spread/Flat Glass vs. Unreinforced PTFE

Unreinforced PTFE laminates offer the ultimate electrical performance by completely eliminating the glass weave and its associated effects.

However, they lack the mechanical rigidity and dimensional stability that glass reinforcement provides. Spread/flat glass offers a crucial balance: excellent electrical properties combined with the physical robustness needed for reliable manufacturing and assembly.

Cost and Complexity

The manufacturing process for spread/flat glass is more complex than for standard woven glass, which typically makes these laminates a more expensive option.

The performance gains must be weighed against the project's budget and specific technical requirements.

Making the Right Choice for Your Application

Selecting the correct laminate is a foundational decision in high-frequency design. Your choice should be dictated by the primary goal of your system.

- If your primary focus is phase-sensitive performance (e.g., phased arrays, advanced radar): Spread/flat glass reinforcement is the optimal choice, providing a superior balance of electrical performance and mechanical stability.

- If your primary focus is ultimate electrical purity (and mechanical stability is a lower priority): Pure, unreinforced PTFE may be the better option, as it completely eliminates any potential for fiber weave effects.

- If your primary focus is cost for a less phase-critical application: A standard woven glass reinforcement may be sufficient and more economical.

Ultimately, choosing a laminate with spread/flat glass reinforcement is an investment in signal integrity for applications where phase accuracy is paramount.

Summary Table:

| Feature | Standard Woven Glass | Spread/Flat Glass |

|---|---|---|

| Electrical Uniformity | Low (causes fiber weave effect) | High (minimizes phase skew) |

| Ideal For | Cost-sensitive, less phase-critical applications | Phase-sensitive applications (e.g., radar, phased arrays) |

| Mechanical Stability | Good | Excellent |

| Cost | Lower | Higher |

Need a PTFE laminate that guarantees signal integrity for your most demanding projects?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom laminates designed for the semiconductor, medical, and telecommunications industries. Our expertise in precision production ensures your high-frequency electronics achieve the phase accuracy and reliability they require.

Contact our experts today to discuss how our custom PTFE solutions can solve your specific design challenges, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability