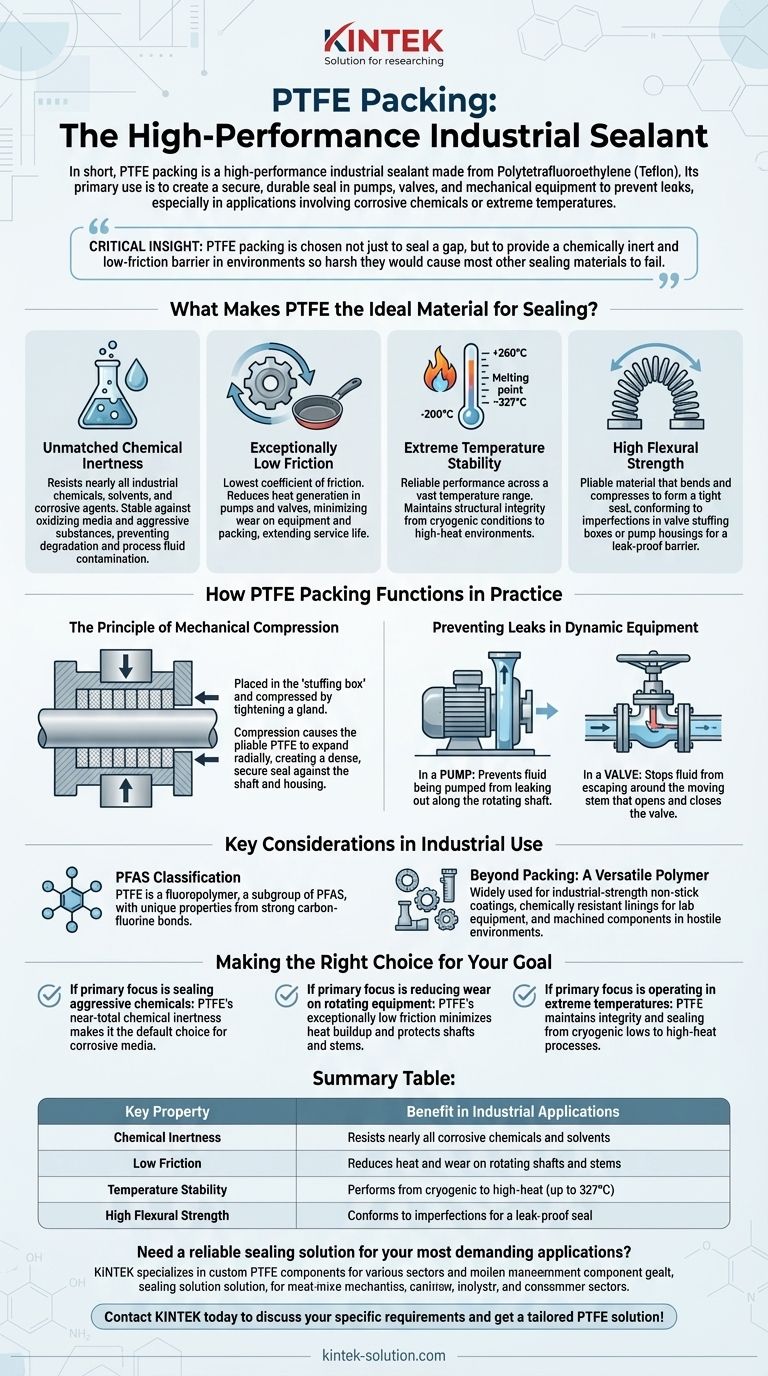

In short, PTFE packing is a high-performance industrial sealant made from Polytetrafluoroethylene, the same material known by the brand name Teflon. Its primary use is to create a secure, durable seal in pumps, valves, and other mechanical equipment to prevent leaks, especially in applications involving corrosive chemicals or extreme temperatures.

The critical insight is that PTFE packing is chosen not just to seal a gap, but to provide a chemically inert and low-friction barrier in environments so harsh they would cause most other sealing materials to fail.

What Makes PTFE the Ideal Material for Sealing?

The effectiveness of PTFE packing stems directly from the unique molecular properties of Polytetrafluoroethylene. These characteristics make it a cost-effective and reliable solution for demanding industrial challenges.

Unmatched Chemical Inertness

PTFE is famous for its resistance to nearly all industrial chemicals, solvents, and corrosive agents.

It remains stable when exposed to oxidizing media and aggressive substances common in chemical processing and oil & gas operations. This inertness prevents the packing from degrading and contaminating the process fluid.

Exceptionally Low Friction

Often recognized for its use in non-stick cookware, PTFE has one of the lowest coefficients of friction of any solid material.

In a pump or valve, this "slippery" surface reduces the heat generated by a rotating shaft or moving stem. This minimizes wear on both the equipment and the packing itself, extending service life.

Extreme Temperature Stability

PTFE performs reliably across a vast temperature range. It maintains its structural integrity and flexibility in cryogenic conditions as well as in high-heat environments, with a melting point around 327°C (621°F).

This allows it to be used in a wide variety of industrial processes without risk of material failure due to temperature fluctuations.

High Flexural Strength

Despite its slick surface, PTFE has high flexural strength, meaning it can be bent and compressed to form a tight seal without breaking.

This allows the packing to conform perfectly to the slight imperfections inside a valve's stuffing box or a pump's housing, ensuring a leak-proof barrier under mechanical pressure.

How PTFE Packing Functions in Practice

PTFE packing is not a rigid gasket but a pliable material, often braided into a rope-like form. It is installed by wrapping it around a shaft or stem and compressing it into a cavity.

The Principle of Mechanical Compression

The packing is placed into the "stuffing box" of a pump or valve. By tightening a component called a gland, the packing is compressed.

This compression causes the pliable PTFE material to expand radially, pushing against the shaft and the housing wall to create a dense, secure seal.

Preventing Leaks in Dynamic Equipment

The primary function is to seal the space around a moving component.

In a pump, it prevents the fluid being pumped from leaking out along the rotating shaft. In a valve, it stops fluid from escaping around the moving stem that opens and closes the valve.

Key Considerations in Industrial Use

While highly effective, it's important to understand the broader context of the material to appreciate its applications and place in the industry.

The PFAS Classification

It is technically accurate to note that PTFE is a type of fluoropolymer, which is a subgroup of chemicals known as PFAS. Its unique properties are a direct result of its strong carbon-fluorine molecular bonds.

Beyond Packing: A Versatile Polymer

The same properties that make PTFE excellent for packing also make it valuable for other industrial uses. It is widely used for industrial-strength non-stick coatings, chemically resistant linings for lab equipment, and as machined components in hostile environments.

Making the Right Choice for Your Goal

Selecting PTFE packing is an engineering decision based on the specific demands of the application.

- If your primary focus is sealing aggressive chemicals: PTFE's near-total chemical inertness makes it the default choice for corrosive media where other elastomers or fibers would quickly degrade.

- If your primary focus is reducing wear on rotating equipment: The exceptionally low friction of PTFE packing minimizes heat buildup and protects pump shafts and valve stems from scoring, reducing maintenance costs.

- If your primary focus is operating in extreme temperatures: PTFE maintains its integrity and sealing capability from cryogenic lows to high-heat industrial processes, offering a uniquely wide operational window.

Ultimately, choosing PTFE packing is a strategic decision for achieving long-term reliability in conditions that demand the highest level of material performance.

Summary Table:

| Key Property | Benefit in Industrial Applications |

|---|---|

| Chemical Inertness | Resists nearly all corrosive chemicals and solvents |

| Low Friction | Reduces heat and wear on rotating shafts and stems |

| Temperature Stability | Performs from cryogenic to high-heat (up to 327°C) |

| High Flexural Strength | Conforms to imperfections for a leak-proof seal |

Need a reliable sealing solution for your most demanding applications?

KINTEK specializes in manufacturing high-performance PTFE components, including custom packing, seals, liners, and labware. Our precision production ensures durability and chemical resistance for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we deliver solutions that withstand extreme conditions and reduce maintenance costs.

Contact KINTEK today to discuss your specific requirements and get a tailored PTFE solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation