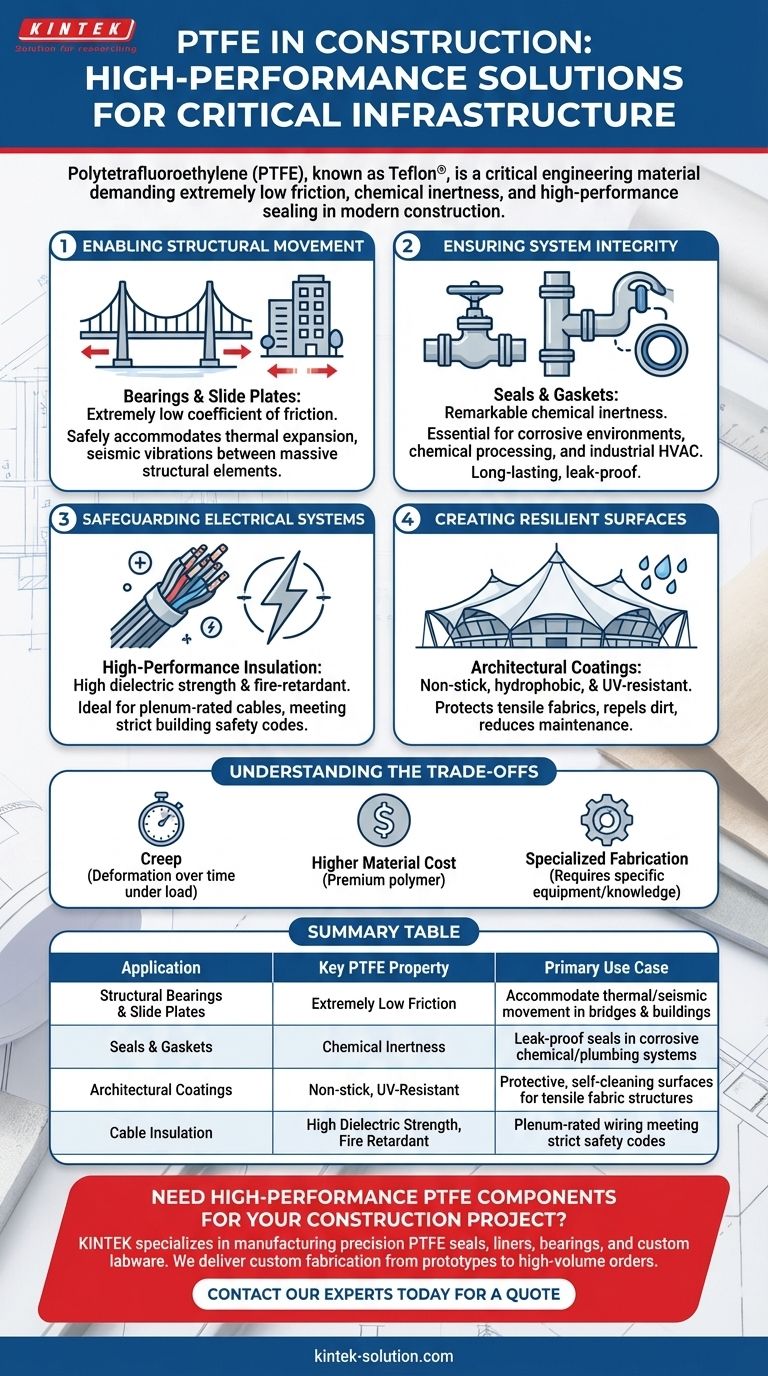

In modern construction, Polytetrafluoroethylene (PTFE) is primarily specified for applications demanding extremely low friction, chemical inertness, and high-performance sealing. Its most critical uses are in structural bearings for bridges and large buildings, high-integrity seals and gaskets for aggressive environments, and as a protective coating for architectural fabrics.

While known colloquially by the brand name Teflon®, PTFE's value in construction extends far beyond non-stick surfaces. It is a specialized engineering material used to solve fundamental challenges of movement, chemical exposure, and system longevity in critical infrastructure.

Why PTFE is a Critical Construction Material

PTFE’s utility in construction is not based on a single feature, but on a unique combination of properties that solve specific engineering problems where conventional materials would fail.

Enabling Structural Movement: Bearings and Slide Plates

The most significant use of PTFE in large-scale construction is in structural bearings and slide plates.

These components are placed between massive structural elements, such as a bridge deck and its support pier, or between sections of a large building.

PTFE's exceptionally low coefficient of friction—one of the lowest of any solid material—allows these huge components to slide past one another with minimal resistance. This safely accommodates thermal expansion and contraction, foundation settling, and even seismic vibrations without transferring destructive stress to the structure.

Ensuring System Integrity: Seals and Gaskets

In building systems, PTFE is the material of choice for seals, washers, and gaskets in demanding environments.

Its remarkable chemical inertness means it will not degrade when exposed to corrosive fluids, aggressive cleaning agents, or industrial chemicals. This makes it essential for seals in chemical processing pipework, industrial HVAC systems, and specialized plumbing.

This resilience ensures a long-lasting, leak-proof seal, preventing costly damage and maintaining system safety over decades.

Safeguarding Electrical Systems: High-Performance Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength and temperature resistance.

This makes it a key material for the insulation on high-performance wiring and cables, particularly plenum-rated cables that run through air circulation spaces in buildings. Its excellent fire-retardant properties are critical for meeting strict building safety codes.

Creating Resilient Surfaces: Architectural Coatings

The non-stick, hydrophobic, and UV-resistant properties of PTFE make it an ideal coating for tensile fabric structures, such as the roofs of stadiums and airports.

A PTFE coating protects the underlying fabric from degradation, repels dirt, and allows rain to wash the surface clean. This drastically reduces maintenance requirements and extends the life of the structure.

Understanding the Trade-offs

While highly effective, PTFE is a specialized material, and specifying it requires awareness of its limitations.

Susceptibility to Creep

Under a sustained, heavy load, PTFE can slowly deform over time in a process known as creep or "cold flow." Structural bearing designs must account for this phenomenon to ensure long-term stability and performance.

Higher Material Cost

PTFE is a premium polymer. Its cost is significantly higher than that of more common sealing or bearing materials like neoprene or other plastics. Its use must be justified by specific performance requirements that other materials cannot meet.

Specialized Fabrication

Working with PTFE can be more complex than with other polymers. It requires specialized knowledge and equipment for machining, welding, and bonding, which can influence project complexity and cost.

Making the Right Choice for Your Project

Selecting PTFE is a decision driven by the need for long-term performance under specific, challenging conditions.

- If your primary focus is accommodating thermal or seismic movement: PTFE structural bearings and slide plates are the industry standard for minimizing stress in bridges and large buildings.

- If your primary focus is creating a leak-proof seal against aggressive chemicals: PTFE gaskets, seals, and pipe liners offer unmatched chemical resistance and system integrity.

- If your primary focus is designing a durable, self-cleaning fabric structure: PTFE-coated architectural fabrics provide exceptional longevity and low maintenance for tensile roofs and facades.

- If your primary focus is specifying fire-resistant, high-performance cabling: PTFE insulation is essential for meeting stringent safety codes in critical electrical applications.

Ultimately, specifying PTFE means investing in resilience and reliability for the most demanding components of your project.

Summary Table:

| Application | Key PTFE Property | Primary Use Case |

|---|---|---|

| Structural Bearings & Slide Plates | Extremely Low Friction | Accommodate thermal/seismic movement in bridges & buildings |

| Seals & Gaskets | Chemical Inertness | Leak-proof seals in corrosive chemical/plumbing systems |

| Architectural Coatings | Non-stick, UV-Resistant | Protective, self-cleaning surfaces for tensile fabric structures |

| Cable Insulation | High Dielectric Strength, Fire Retardant | Plenum-rated wiring meeting strict safety codes |

Need high-performance PTFE components for your construction project? KINTEK specializes in manufacturing precision PTFE seals, liners, bearings, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your critical infrastructure components meet the highest standards of durability and chemical resistance. Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How have material producers attempted to mitigate creep in PTFE? Discover the Best Strategies for Your Application

- How does ETFE differ from true Teflon products? Uncover the Key Trade-offs for Your Application

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application

- What is Polytetrafluoroethylene (PTFE) and what are its main types? Unlock High-Performance Solutions

- Why is Teflon considered a relatively expensive plastic? A Guide to Its High-Performance Value

- What are the benefits of using Teflon in manufacturing projects? Solve Critical Surface Interaction Problems

- What are the applications of polymers in drug delivery systems? Control Release & Improve Efficacy

- What is Expanded PTFE and how does it differ from regular PTFE? Choosing the Right Material for Your Application