At its core, PTFE stands for Polytetrafluoroethylene. This is the chemical name for a versatile synthetic fluoropolymer. It is far more commonly known by its most famous brand name, Teflon.

Polytetrafluoroethylene (PTFE) is a high-performance synthetic material, celebrated as Teflon for its non-stick properties. Its unique molecular structure provides exceptional resistance to heat, chemicals, and friction, making it invaluable in industries from cookware to electronics.

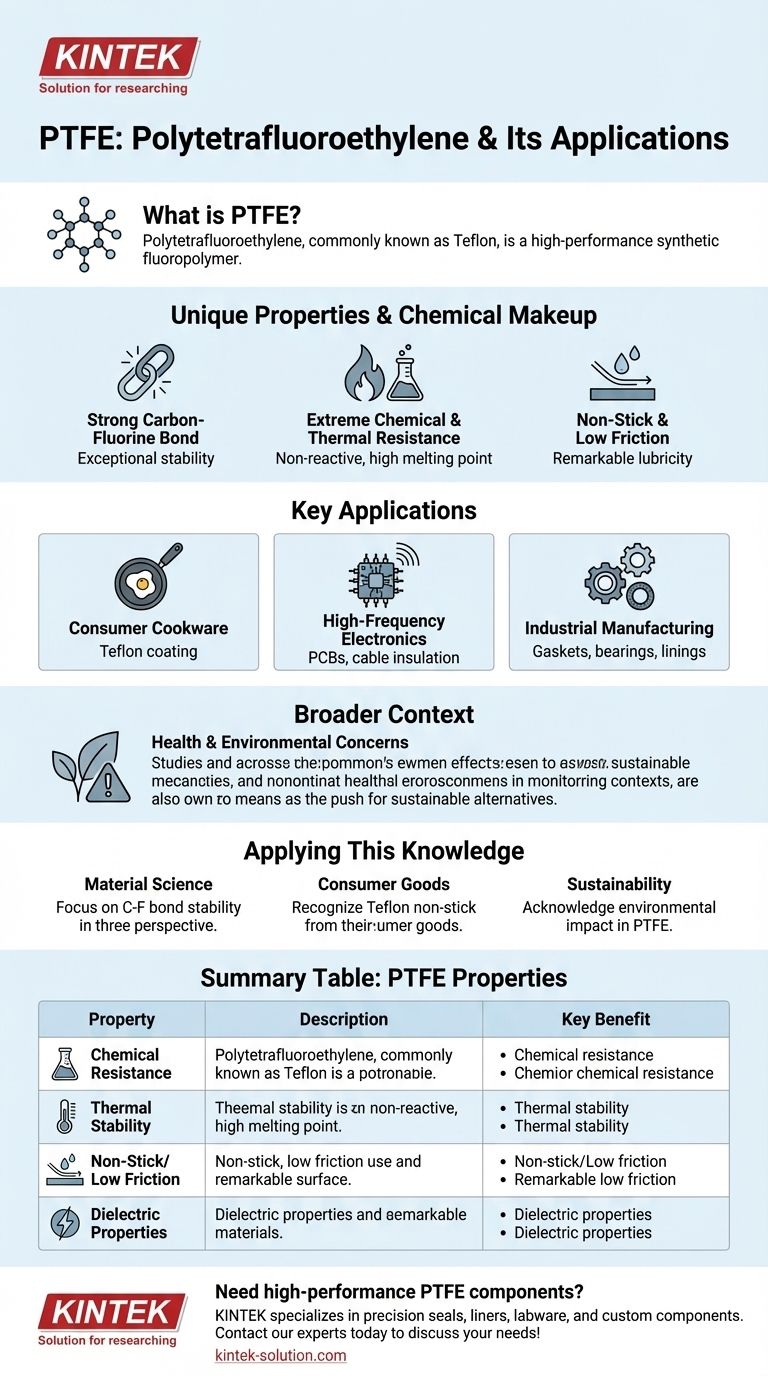

What Gives PTFE Its Unique Properties?

The utility of PTFE isn't accidental; it stems directly from its unique chemical makeup. Understanding this foundation is key to appreciating its widespread use.

The Power of the Carbon-Fluorine Bond

PTFE is a fluoropolymer, meaning it's a large molecule (a polymer) built with a backbone of carbon atoms completely surrounded by fluorine atoms.

The bond between carbon and fluorine is exceptionally strong. This molecular stability is the primary source of the material's most valued characteristics.

Extreme Chemical and Thermal Resistance

Because of its strong bonds, PTFE is highly non-reactive. It can withstand a wide range of chemicals and has a very high melting point.

This makes it an ideal material for handling corrosive substances or for use in high-temperature environments where other materials would degrade.

The Famous Non-Stick Surface

PTFE is also known for its remarkable lubricity, or "slipperiness." It has one of the lowest coefficients of friction of any solid material.

This property is why it is famous as a non-stick coating on frying pans and other cookware, preventing food from adhering to the surface.

Where Is PTFE Found?

While its most famous application is in the kitchen, PTFE's properties make it a critical component in many high-tech and industrial sectors.

Consumer Cookware

The most recognized use of PTFE is under the Teflon brand name for non-stick coatings on pans, pots, and bakeware.

High-Frequency Electronics

Due to its excellent dielectric properties, PTFE is a material of choice for manufacturing printed circuit boards (PCBs) and cable insulation used in high-frequency radio and microwave systems.

Industrial Manufacturing

As a strong, durable, and nonflammable material, PTFE is used for seals, gaskets, bearings, and linings in industrial equipment, especially where chemical resistance is required.

Understanding the Broader Context

No material is without its complexities. The widespread use of PTFE has led to important discussions regarding its life cycle and impact.

Health and Environmental Concerns

In recent years, studies have raised concerns about the potential adverse effects of PTFE and related compounds on human health and the environment.

These discussions have prompted many industries to actively seek and develop safer, more sustainable alternatives to traditional fluoropolymers.

Applying This Knowledge

Understanding PTFE means recognizing its distinct roles across different contexts.

- If your primary focus is material science: Recognize PTFE for its incredibly strong Carbon-Fluorine bond, which is the source of its thermal stability and chemical inertness.

- If your primary focus is consumer goods: You know it as Teflon, the brand name for the revolutionary non-stick coating that transformed modern kitchens.

- If your primary focus is sustainability: It's critical to acknowledge the ongoing concerns about its environmental impact, which are driving innovation in alternative materials.

Ultimately, PTFE is a landmark material whose remarkable performance is now balanced against the modern imperative for environmental and health safety.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Resistance | Highly non-reactive to most chemicals | Ideal for corrosive environments |

| Thermal Stability | High melting point, withstands extreme temperatures | Suitable for high-heat applications |

| Non-Stick/Low Friction | One of the lowest coefficients of friction | Prevents sticking, reduces wear |

| Dielectric Properties | Excellent electrical insulator | Critical for high-frequency electronics |

Need high-performance PTFE components for your application? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring the chemical resistance, thermal stability, and low friction your projects require. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the common uses of Teflon? A Guide to PTFE's Versatile Applications

- Why is PTFE considered non-reactive? The Power of an Unbreakable Molecular Bond

- What types of finished products are made from PTFE? Seals, Bearings, Labware & More

- What makes Teflon a valuable ingredient in personal care product formulations? Enhance Performance with Unique Properties

- How is Teflon used in electronics? As a High-Performance Insulator and Semiconductor Component

- What are the friction and surface properties of PTFE? Discover the Science Behind Its Low Friction & Non-Stick Performance

- What is the maximum service temperature for PTFE? A Guide to Safe & Reliable Use

- What is Glass-Filled PTFE and what are its properties? A Guide to Enhanced PTFE Performance