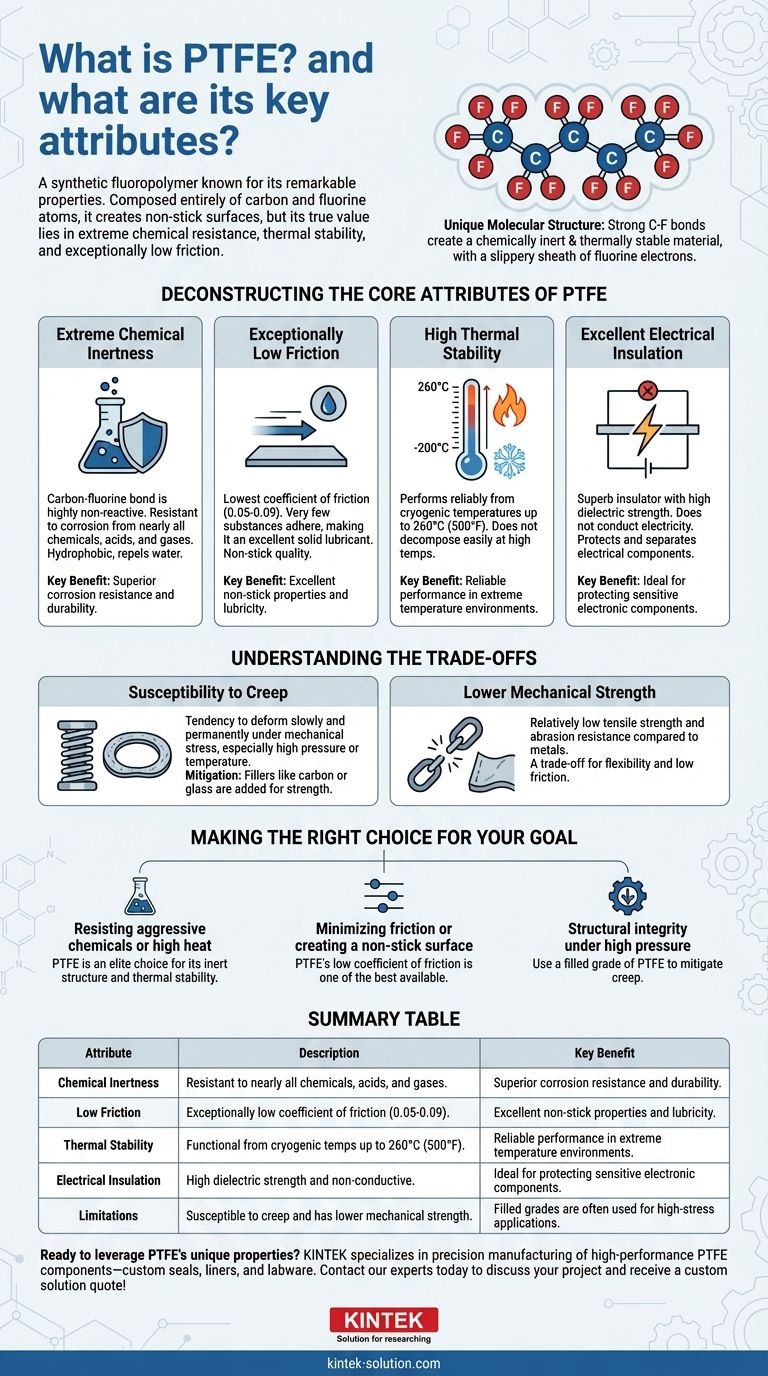

At its core, Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its remarkable and diverse set of properties. Composed entirely of carbon and fluorine atoms, this material is famous for creating non-stick surfaces, but its true value lies in its extreme chemical resistance, thermal stability, and exceptionally low friction.

PTFE's power comes from its unique molecular structure. The incredibly strong bonds between its carbon and fluorine atoms create a chemically inert and thermally stable material, while the external sheath of fluorine electrons gives it an unrivaled "slippery" or non-stick quality.

Deconstructing the Core Attributes of PTFE

To understand why PTFE is so versatile, we must examine its fundamental properties, which all stem from its simple but powerful chemical makeup.

The Foundation: Extreme Chemical Inertness

The carbon-fluorine bond is one of the strongest in organic chemistry. This makes the PTFE molecule highly non-reactive.

Because of this stability, PTFE is resistant to corrosion from nearly all known chemicals, acids, and gases. It is also hydrophobic, meaning it repels water and water-containing substances.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid, with values often cited between 0.05 and 0.09.

This property is responsible for its famous non-stick quality. It means very few substances will adhere to its surface, and objects slide across it with minimal resistance, making it an excellent solid lubricant.

High Thermal Stability

PTFE performs reliably across a vast temperature range. It remains functional from cryogenic temperatures up to approximately 260°C (500°F).

It does not readily decompose at high temperatures, ensuring its properties remain consistent in demanding thermal environments found in laboratories and industrial processes.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength. It does not conduct electricity, making it an ideal material for protecting and separating electrical components.

This property is critical for its use in high-performance wiring, cable insulation, and printed circuit boards.

Understanding the Trade-offs

No material is perfect. While PTFE's attributes are exceptional, it's crucial to understand its limitations to use it effectively.

Susceptibility to Creep

One of the primary weaknesses of pure PTFE is creep, which is the tendency for a solid material to deform slowly and permanently under mechanical stress.

Under high pressure or temperature, especially in applications like gaskets, pure PTFE can begin to "flow" out of place. To counteract this, fillers like carbon, graphite, or glass are often added to enhance its strength and creep resistance.

Lower Mechanical Strength

Compared to metals or some engineering plastics, PTFE has relatively low tensile strength and abrasion resistance. It is a soft material.

This is a direct trade-off for its flexibility and low friction. For applications requiring high structural rigidity or resistance to wear, filled PTFE grades or alternative materials may be more suitable.

Making the Right Choice for Your Goal

Understanding this balance of properties is the key to leveraging PTFE's strengths correctly in any project.

- If your primary focus is resisting aggressive chemicals or high heat: PTFE is an elite choice due to its inert molecular structure and thermal stability.

- If your primary focus is minimizing friction or creating a non-stick surface: PTFE's exceptionally low coefficient of friction makes it one of the best materials available.

- If your primary focus is structural integrity under high pressure: You should use a filled grade of PTFE to mitigate its natural tendency to creep under load.

By matching PTFE's unique profile to your specific challenge, you can harness its full potential.

Summary Table:

| Attribute | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all chemicals, acids, and gases. | Superior corrosion resistance and durability. |

| Low Friction | Exceptionally low coefficient of friction (0.05-0.09). | Excellent non-stick properties and lubricity. |

| Thermal Stability | Functional from cryogenic temps up to 260°C (500°F). | Reliable performance in extreme temperature environments. |

| Electrical Insulation | High dielectric strength and non-conductive. | Ideal for protecting sensitive electronic components. |

| Limitations | Susceptible to creep and has lower mechanical strength. | Filled grades are often used for high-stress applications. |

Ready to leverage PTFE's unique properties for your application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get a component that perfectly balances PTFE's exceptional chemical resistance and non-stick properties with the mechanical integrity required for your specific challenge.

Contact our experts today to discuss your project and receive a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE/Teflon used in non-stick cookware? Unlock the Science of Frictionless Cooking

- What are the three main steps in the manufacturing process of PTFE? From Monomer to High-Performance Polymer

- What is Polytetrafluoroethylene (PTFE) composed of? The Power of Carbon & Fluorine

- What are the environmental properties of PTFE? Balancing Performance with Sustainability

- Why has PTFE fascinated scientists and science students? Unlocking the Secrets of a Wonder Material

- What PTFE formulations are recommended for automotive and aerospace applications and why? Optimize with Bronze-Filled PTFE

- Why is PTFE considered safe for food and pharmaceutical applications? Ensuring Product Purity and Compliance

- What is PTFE and what is its commercial name? A Guide to Teflon and ePTFE