At its core, a PTFE lined dual plate check valve is a specialized industrial valve designed to perform one critical function: prevent backflow in pipelines that handle highly corrosive or high-purity fluids. It combines the compact, efficient design of a dual plate check valve with the exceptional chemical resistance of a Polytetrafluoroethylene (PTFE) liner, which acts as a protective shield for the valve's internal metal components.

The crucial insight is that this valve isn't just a simple backflow preventer. It's an engineered solution specifically for harsh chemical environments where a standard metal valve would quickly corrode and fail, compromising both the system and the purity of the media.

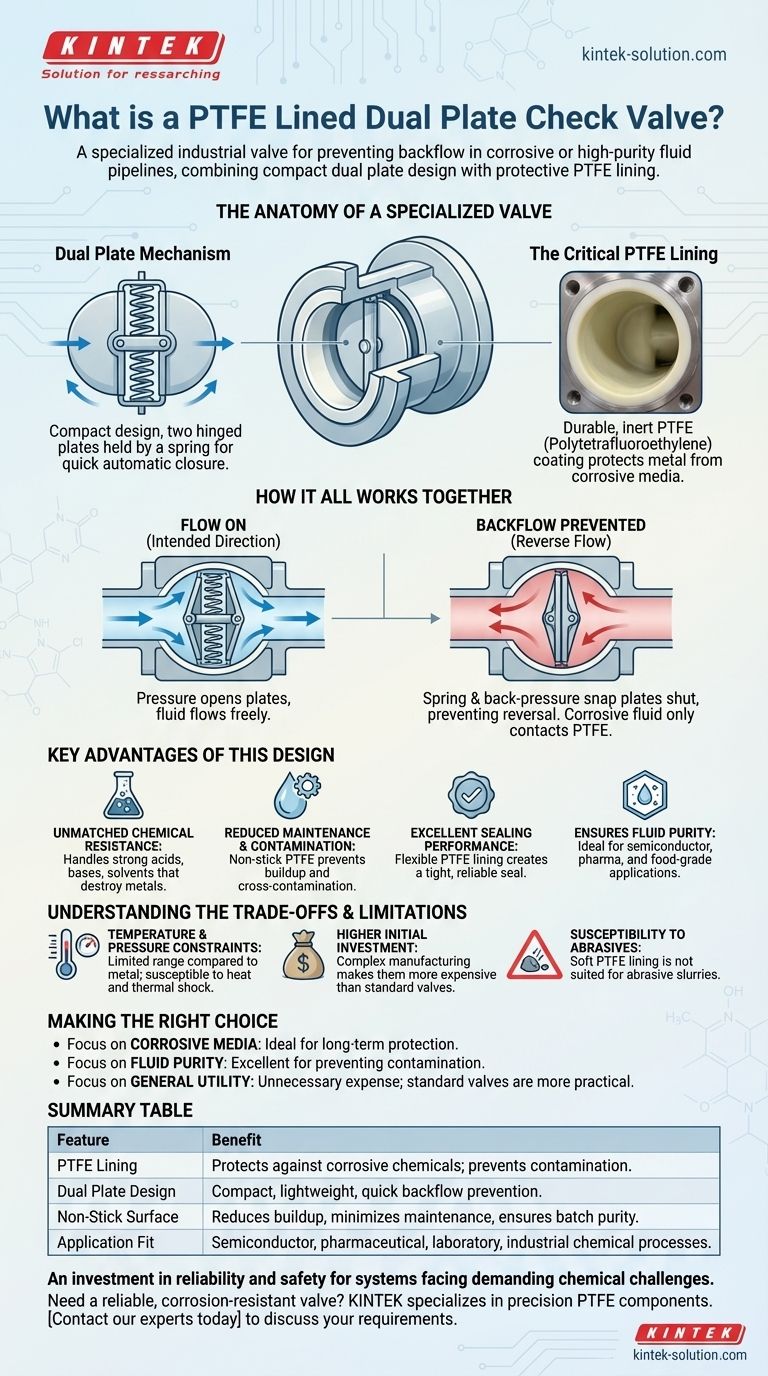

The Anatomy of a Specialized Valve

To understand its value, we need to look at its two primary features: the mechanical design and the protective lining.

The Dual Plate Mechanism

A dual plate check valve, also known as a wafer check valve, features a simple yet effective design. It consists of two semi-circular plates, or "doors," hinged on a central pin.

These plates are held shut by a spring. When fluid flows in the intended direction, the pressure pushes the two plates open, allowing the media to pass through.

If the flow stops or attempts to reverse, the spring and the back-pressure instantly snap the plates shut, creating a seal and preventing any backflow. This design is known for being lightweight, compact, and easy to install between pipe flanges.

The Critical PTFE Lining

The key to this valve's performance in harsh conditions is its internal PTFE (Polytetrafluoroethylene) lining. This is a durable, engineered plastic coating applied to all wetted surfaces of the valve.

PTFE creates a non-reactive, protective barrier between the valve's metal body and the fluid passing through it. This lining is what gives the valve its unique capabilities.

How It All Works Together

The combination is straightforward but powerful. The dual plate mechanism provides reliable, automatic backflow prevention, while the PTFE lining ensures the valve can survive and operate flawlessly in aggressive media.

The corrosive fluid only ever makes contact with the inert PTFE liner, never the structural metal of the valve body or plates. This protects the valve from chemical attack and prevents metallic ions from leaching into and contaminating the process fluid.

Key Advantages of This Design

Choosing a PTFE lined valve is a deliberate decision made to gain specific, critical advantages in demanding applications.

Unmatched Chemical Resistance

This is the primary reason for using a PTFE lined valve. It can handle a vast range of aggressive chemicals, including strong acids, bases, and solvents that would rapidly destroy most metals.

Reduced Maintenance and Contamination

PTFE has an extremely low coefficient of friction, making it a "non-stick" surface. This property prevents media from building up inside the valve, which reduces the need for frequent cleaning and minimizes the risk of cross-contamination between batches.

Excellent Sealing Performance

The inherent flexibility of the PTFE material helps create a tight, reliable seal when the plates close, which is crucial for preventing leaks in systems handling hazardous materials.

Understanding the Trade-offs and Limitations

While powerful, this specialized valve is not a universal solution. Its unique construction comes with specific limitations that are critical to understand.

Temperature and Pressure Constraints

PTFE has a more limited operating temperature range than metal. It can be damaged by excessive heat, high pressure, or sudden thermal shock, which can cause the lining to crack or delaminate.

Higher Initial Investment

The complex manufacturing process required to apply a uniform, high-integrity PTFE lining makes these valves significantly more expensive upfront compared to standard cast iron or stainless steel check valves.

Susceptibility to Abrasives

While chemically robust, the PTFE lining is a softer material than metal. It is not well-suited for applications with highly abrasive slurries, as the abrasive particles can physically wear away or damage the protective lining over time.

Making the Right Choice for Your Application

Selecting the correct valve comes down to aligning its specific strengths with the demands of your system.

- If your primary focus is handling corrosive media: This valve is the ideal choice, providing long-term protection against chemical attack where standard valves would fail.

- If your primary focus is maintaining fluid purity: The inert, non-stick PTFE surface makes it an excellent option for pharmaceutical, semiconductor, or food-grade applications where preventing contamination is critical.

- If your primary focus is general utility service (e.g., water or air): This valve is likely an unnecessary and cost-prohibitive expense; a standard, unlined metal check valve would be far more practical.

Ultimately, choosing a PTFE lined dual plate check valve is an investment in reliability and safety for systems facing the most demanding chemical challenges.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Lining | Protects against corrosive acids, bases, and solvents; prevents contamination. |

| Dual Plate Design | Compact, lightweight, and provides quick, automatic backflow prevention. |

| Non-Stick Surface | Reduces media buildup, minimizes maintenance, and ensures batch purity. |

| Application Fit | Ideal for semiconductor, pharmaceutical, laboratory, and industrial chemical processes. |

Need a reliable, corrosion-resistant valve for your critical process?

At KINTEK, we specialize in precision PTFE components, including custom-fabricated seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your valves and components meet the highest standards for chemical resistance and purity.

Let us help you protect your system and your product. Contact our experts today to discuss your specific requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE's porous structure support medical applications? Unlocking Biocompatible Scaffolds and Filtration

- What are the advantages of oil-impregnated PTFE gland packing? Superior Sealing for Harsh and Sanitary Applications

- What are the advantages of using PTFE combined with glass fiber aggregates? Achieve Superior Strength & Durability

- What are the advantages of Teflon square bars? Solve Extreme Engineering Challenges

- What are the primary uses of PTFE polymer-plastic ball bearings? Ideal for Harsh & Sensitive Environments

- What are the advantages of PTFE lined butterfly valves? Superior Chemical Resistance & Cost-Effective Performance

- What are the limitations of PTFE gaskets in high-temperature environments? Understanding Thermal Degradation and Creep

- What are the limitations of PTFE in ball valve seat applications? Avoid Costly Seal Failures