The most notable downside of PTFE is its poor mechanical strength. While renowned for its chemical resistance and low friction, pure PTFE is a very soft material that is highly susceptible to "creep" or cold flow, meaning it will deform permanently under sustained pressure, especially at elevated temperatures.

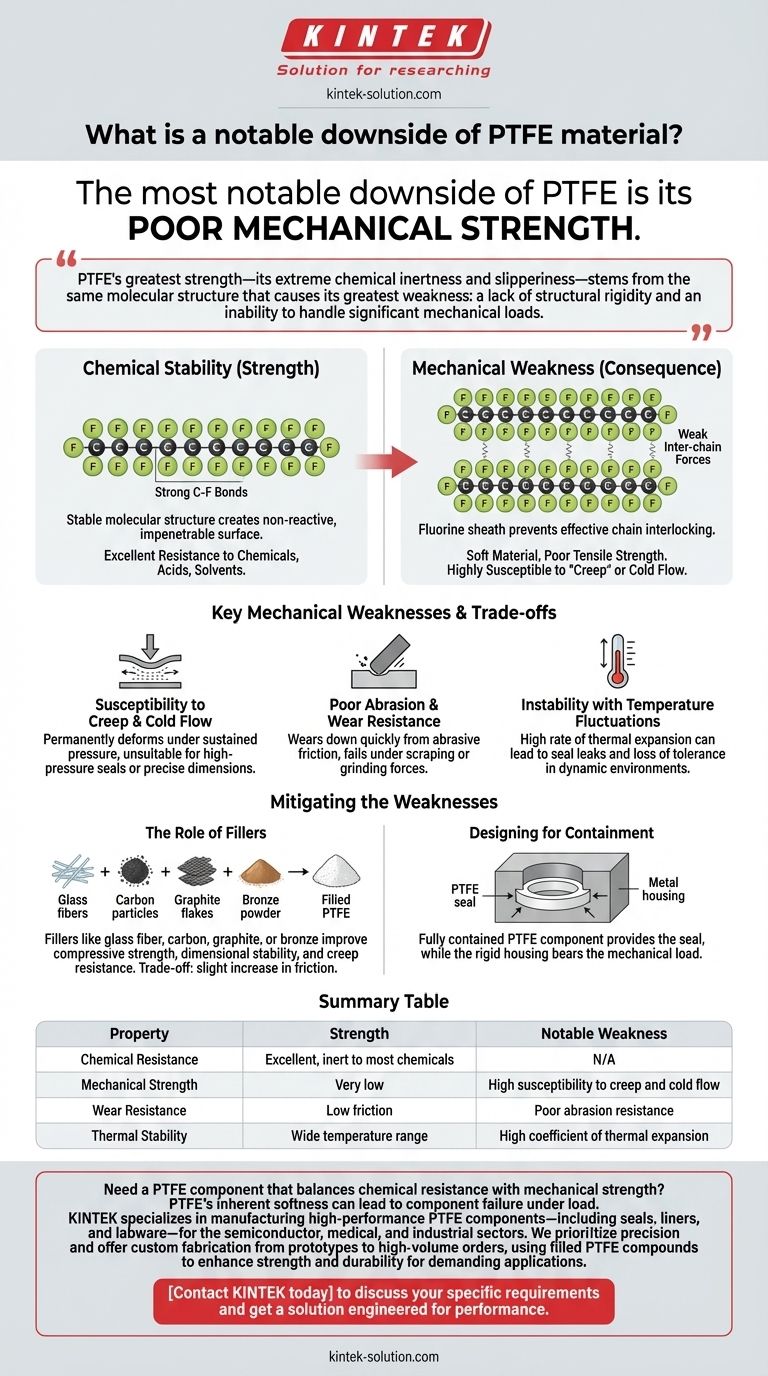

PTFE's greatest strength—its extreme chemical inertness and slipperiness—stems from the same molecular structure that causes its greatest weakness: a lack of structural rigidity and an inability to handle significant mechanical loads.

The Core Compromise: Chemical Stability vs. Mechanical Strength

To understand PTFE's limitations, you must first understand its chemical makeup. Its properties are not independent features but are directly linked.

The Source of Its Chemical Resistance

PTFE consists of a long chain of carbon atoms, with each carbon completely sheathed by larger fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable.

This stable molecular structure is what gives PTFE its remarkable resistance to nearly all chemicals, acids, and solvents. It effectively presents a non-reactive, impenetrable surface.

The Consequence: Low Structural Integrity

While the individual bonds are strong, the interaction between these polymer chains is weak. The fluorine sheath prevents the chains from interlocking or bonding effectively with each other.

This results in a soft material with poor tensile strength. As one reference noted, it is so soft you can often leave an imprint with just a fingernail.

Understanding the Trade-offs: Key Mechanical Weaknesses

For any practical application, you must weigh PTFE's benefits against its specific mechanical failures. Ignoring these can lead to component failure.

Susceptibility to Creep and Cold Flow

This is the most critical weakness in mechanical design. When a constant load or pressure is applied to PTFE, the material will slowly and permanently deform or "flow" out of shape.

This makes pure PTFE unsuitable for high-pressure seals or structural components that must maintain precise dimensions over time.

Poor Abrasion and Wear Resistance

Because the material is so soft, it wears down quickly when subjected to friction from abrasive surfaces. It excels in low-friction sliding applications but fails when subjected to scraping or grinding forces.

Instability with Temperature Fluctuations

PTFE has a relatively high rate of thermal expansion. In environments with large or rapid temperature swings, components can change dimension significantly, leading to leaks in seals or loss of tolerance.

For this reason, it is often secured with high-pressure clamps to help contain it and compensate for these changes.

Mitigating the Weaknesses

Engineers have developed methods to compensate for PTFE's inherent softness while retaining its other desirable properties.

The Role of Fillers

The most common solution is to add fillers to the raw PTFE material. Adding materials like glass fiber, carbon, graphite, or bronze creates a composite material often referred to as "filled PTFE."

These fillers act as a reinforcing matrix within the plastic, dramatically improving its compressive strength, dimensional stability, and resistance to creep. The trade-off is often a slight increase in the coefficient of friction and a change in chemical compatibility.

Designing for Containment

Another strategy is to design components where the PTFE is fully contained or supported by a more rigid material, such as a metal housing.

In this approach, the PTFE provides the seal or low-friction surface, while the housing bears the mechanical load and prevents the material from deforming.

Making the Right Choice for Your Application

Ultimately, the decision to use PTFE depends entirely on the mechanical and thermal demands of your project.

- If your primary focus is chemical resistance or a low-friction surface in a low-load, stable environment: Pure PTFE is an excellent and cost-effective choice.

- If your application involves significant mechanical stress, abrasion, or must hold a precise dimension under load: Pure PTFE is unsuitable and will likely fail.

- If you need a balance of chemical inertness and improved mechanical strength: You must specify a filled grade of PTFE appropriate for the load and temperature requirements.

Choosing the right material requires understanding that PTFE's exceptional benefits come with a direct and significant trade-off in mechanical performance.

Summary Table:

| PTFE Property | Strength | Notable Weakness |

|---|---|---|

| Chemical Resistance | Excellent, inert to most chemicals | N/A |

| Mechanical Strength | Very low | High susceptibility to creep and cold flow |

| Wear Resistance | Low friction | Poor abrasion resistance |

| Thermal Stability | Wide temperature range | High coefficient of thermal expansion |

Need a PTFE component that balances chemical resistance with mechanical strength?

PTFE's inherent softness can lead to component failure under load. KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders, using filled PTFE compounds to enhance strength and durability for demanding applications.

Contact KINTEK today to discuss your specific requirements and get a solution engineered for performance.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance