PTFE lined butterfly valves are a cornerstone in any industry that handles corrosive, toxic, or high-purity media. They are most commonly used in chemical processing, petrochemical, pharmaceutical, water treatment, and power generation sectors. Their prevalence is due to the unique properties of Polytetrafluoroethylene (PTFE), which offers near-universal chemical resistance and a non-contaminating surface.

The decision to use a PTFE lined butterfly valve is less about the industry itself and more about the specific fluid or gas being managed. These valves are chosen when the primary requirements are preventing chemical attack on the valve components and guaranteeing the absolute purity of the media passing through it.

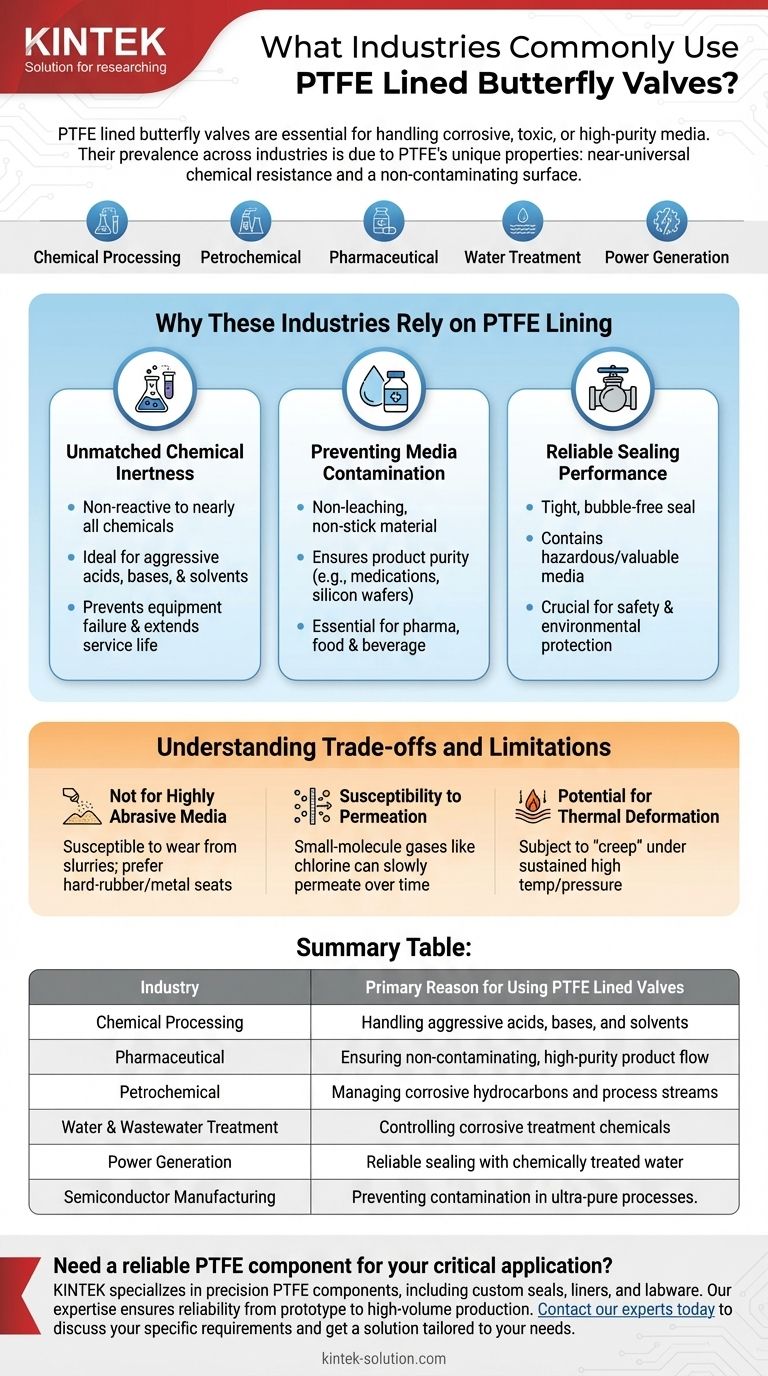

Why These Industries Rely on PTFE Lining

The selection of a PTFE lined valve is driven by a few critical performance characteristics that are indispensable in demanding operational environments.

Unmatched Chemical Inertness

PTFE is famous for being non-reactive to nearly all chemicals, including aggressive acids, bases, and solvents. This makes it the ideal choice for chemical and petrochemical plants where corrosive substances would quickly degrade standard metal or rubber-lined valves.

This inertness prevents equipment failure, ensures operational safety, and extends the service life of the valve significantly.

Preventing Media Contamination

In industries like pharmaceuticals, food and beverage, and semiconductor manufacturing, product purity is non-negotiable. PTFE is a non-leaching, non-stick material, meaning it will not shed particles or contaminate the process fluid.

This ensures that the final product, whether it's a medication or a silicon wafer, remains free of impurities introduced by the processing equipment.

Reliable Sealing Performance

PTFE lined butterfly valves provide a tight, bubble-free seal. This is crucial for containing hazardous or valuable media, preventing leaks that could cause safety incidents, environmental damage, or financial loss.

This reliable sealing is essential in applications from power generation, where chemically treated water must be controlled, to environmental protection systems managing industrial effluent.

Wide Temperature Tolerance

While not suitable for extreme high-temperature services like steam, PTFE maintains its integrity and performance across a broad and useful temperature range. This versatility allows it to be specified for both ambient and moderately heated processes without concern for material degradation.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application and avoiding premature failure.

Not for Highly Abrasive Media

PTFE is a relatively soft material. While excellent for corrosive liquids and gases, it can be susceptible to wear from slurries containing hard, abrasive particles. In applications found in mining or foundries, a hard-rubber or metal-seated valve is often a more durable choice.

Susceptibility to Permeation

Certain small-molecule gases, like chlorine or hydrogen, can slowly permeate through the PTFE liner over time, especially at higher temperatures. In these critical services, careful engineering review is required to ensure long-term integrity.

Potential for Thermal Deformation

Under sustained high temperatures and pressure, PTFE can be subject to "creep" or deformation. This can eventually compromise the valve's sealing capability. For this reason, pressure and temperature ratings provided by the manufacturer must be strictly observed.

Making the Right Choice for Your Goal

Selecting the correct valve requires a clear understanding of your primary operational goal.

- If your primary focus is handling highly corrosive or toxic media: The superior chemical inertness of a PTFE liner provides the safest and most reliable long-term solution.

- If your primary focus is maintaining absolute product purity: A PTFE lined valve is the industry standard for preventing contamination in pharmaceutical, food, and semiconductor applications.

- If your primary focus is managing abrasive slurries or high-pressure steam: You should explore alternatives like metal-seated or specialized rubber-lined valves designed for those specific challenges.

Ultimately, specifying a PTFE lined butterfly valve is a decision driven by the fundamental need for chemical compatibility and purity in your process.

Summary Table:

| Industry | Primary Reason for Using PTFE Lined Valves |

|---|---|

| Chemical Processing | Handling aggressive acids, bases, and solvents |

| Pharmaceutical | Ensuring non-contaminating, high-purity product flow |

| Petrochemical | Managing corrosive hydrocarbons and process streams |

| Water & Wastewater Treatment | Controlling corrosive treatment chemicals |

| Power Generation | Reliable sealing with chemically treated water |

| Semiconductor Manufacturing | Preventing contamination in ultra-pure processes |

Need a reliable PTFE component for your critical application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your equipment handles corrosive or high-purity media with absolute reliability—from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability