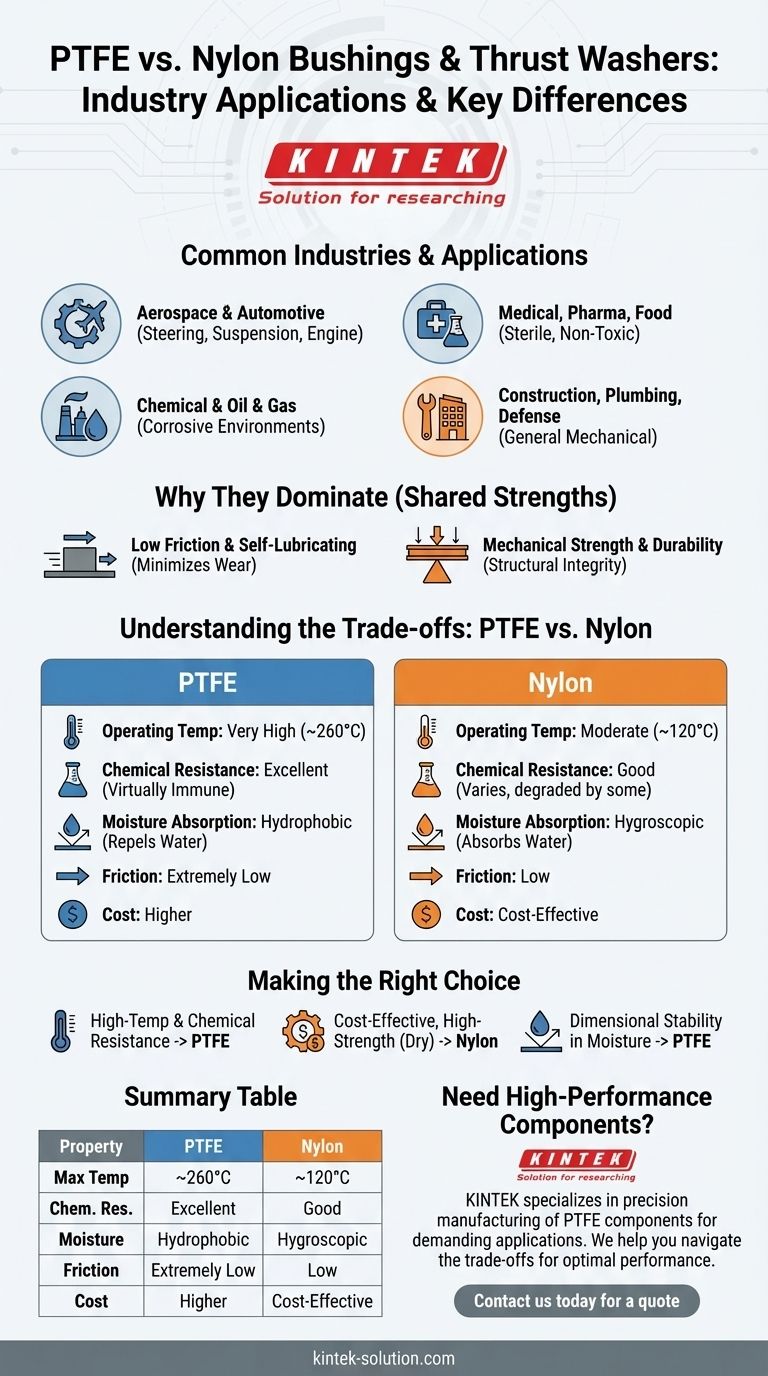

At a glance, PTFE and nylon bushings and washers are staples in demanding industries like aerospace, automotive, medical, and chemical processing. Their widespread use is driven by their unique combination of mechanical strength, low friction, and self-lubricating characteristics that solve critical engineering challenges.

While both PTFE and nylon serve similar functions in overlapping industries, the decision between them is not arbitrary. The choice hinges on specific operating conditions, with PTFE excelling in extreme temperature and chemical environments, while nylon offers a robust, cost-effective solution for general mechanical applications.

Why These Materials Dominate

The selection of a bushing or washer is determined by the environment it must survive. Both PTFE and nylon are high-performance thermoplastics, but their distinct properties make them suitable for different challenges.

The Power of Low Friction

Both materials exhibit an exceptionally low coefficient of friction. This means parts can move against each other with minimal resistance, reducing wear and the need for external lubrication like grease or oil.

This self-lubricating property is critical in applications where maintenance is difficult or contamination from lubricants is unacceptable, such as in food processing or medical devices.

Mechanical Strength and Durability

Bushings and washers are fundamentally mechanical components that must bear loads and resist deformation. Nylon and PTFE provide the necessary structural integrity to handle significant stress in assemblies.

This ensures a long service life and reliable performance in everything from automotive steering columns to industrial machinery.

Industry-Specific Applications and Choices

While many industries use both materials, the specific application often dictates which one is the superior choice.

Aerospace and Automotive

These industries demand reliability and performance under dynamic loads. Bushings and washers made from PTFE and nylon are used in steering systems, suspension components, and engine compartments to reduce vibration and wear.

PTFE is often favored in high-temperature areas or where exposure to aggressive fluids is a concern.

Medical, Pharmaceutical, and Food Processing

These sectors require materials that are non-toxic and easy to sterilize. PTFE is the dominant choice here due to its extreme chemical inertness and high-temperature resistance.

It doesn't react with biological materials or harsh cleaning agents, making it ideal for medical implants, pharmaceutical processing equipment, and food-grade machinery.

Chemical Processing and Oil & Gas

In environments with corrosive chemicals and extreme temperatures, material stability is paramount. PTFE's unparalleled chemical resistance makes it the default material for seals, gaskets, and bushings in chemical plants and refineries.

Construction, Plumbing, and Defense

These industries utilize bushings and washers in a wide range of mechanical systems. The choice between nylon and PTFE often comes down to a balance of performance and cost for the specific application.

Nylon is frequently used for general-purpose, high-load applications, while PTFE is specified for more demanding environmental conditions.

Understanding the Trade-offs: PTFE vs. Nylon

Choosing incorrectly can lead to premature component failure. The decision between these two materials comes down to a few key differences.

Operating Temperature

PTFE has a significantly wider operating temperature range, performing reliably in extreme heat where nylon would fail.

Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to acids, bases, and solvents, whereas nylon can be degraded by certain strong chemicals.

Moisture Absorption

This is a critical distinction. Nylon is hygroscopic, meaning it absorbs moisture from the air, which can cause it to swell and change its dimensions.

PTFE is hydrophobic—it repels water. This makes it a far more stable choice for applications in humid or wet environments, such as marine or plumbing systems.

Cost and General Strength

Nylon often provides excellent mechanical strength and wear resistance at a lower price point, making it a highly cost-effective choice for applications within its operational limits.

Making the Right Choice for Your Application

Your final selection should be guided by a clear understanding of your component's operating environment.

- If your primary focus is high-temperature performance or aggressive chemical resistance: PTFE is the only reliable choice.

- If your primary focus is a cost-effective, high-strength solution in a dry, temperature-controlled environment: Nylon is an excellent and economical option.

- If your primary focus is dimensional stability in the presence of moisture or humidity: PTFE's hydrophobic nature makes it the superior material.

Ultimately, selecting the right material is about matching its inherent properties to the specific demands of your application.

Summary Table:

| Property | PTFE | Nylon |

|---|---|---|

| Max Operating Temp | Very High (~260°C) | Moderate (~120°C) |

| Chemical Resistance | Excellent | Good (varies) |

| Moisture Absorption | Hydrophobic (Repels Water) | Hygroscopic (Absorbs Water) |

| Friction | Extremely Low | Low |

| Cost | Higher | Cost-Effective |

Need High-Performance PTFE or Nylon Components?

Choosing the wrong bushing or washer material can lead to costly downtime and component failure. KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs between PTFE and nylon to ensure optimal performance, longevity, and cost-efficiency for your specific operating environment. From custom prototypes to high-volume production, our expertise ensures you get the right part for the job.

Contact us today to discuss your project requirements and receive a quote: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE packing over graphite packing? Maximize Chemical Resistance & Purity

- What are the advantages of using PTFE Lip Seals in high-speed rotary applications? Achieve Superior Speed and Reliability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- In what industries are PTFE instrumentation tube fittings commonly used? Ensuring Purity and Chemical Resistance

- What type of valves are most suitable for highly corrosive or chemical industries? The Definitive Guide to PTFE Lined Butterfly Valves

- What are the limitations of POM as a ball valve seat material? Key Risks & Safer Alternatives

- How do energized PTFE seals work? Achieve Reliable Sealing from Zero to High Pressure

- How should application-specific temperature requirements be assessed for seal selection? Avoid Failure with a Complete Thermal Profile