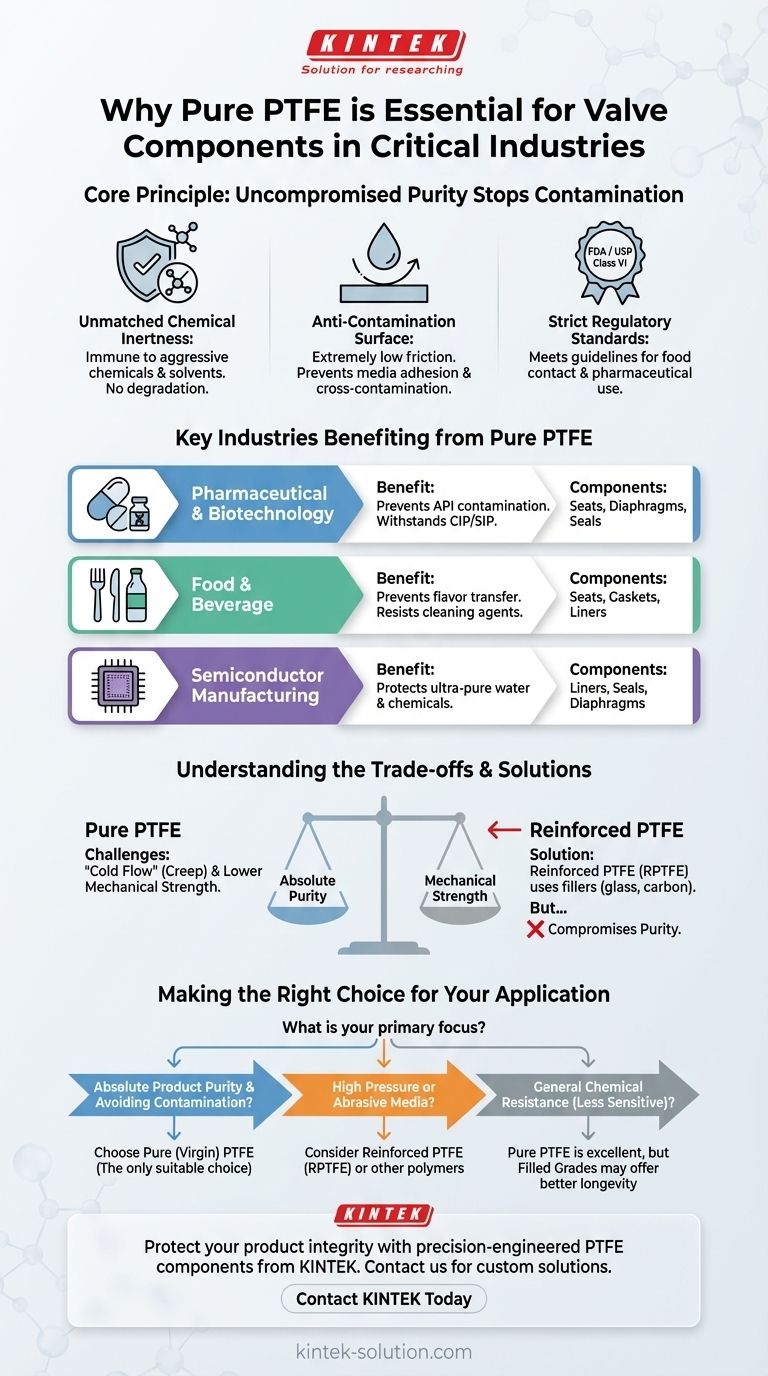

Industries where purity is non-negotiable rely on pure Polytetrafluoroethylene (PTFE) for their critical valve components. The primary beneficiaries are the pharmaceutical, food and beverage, and semiconductor manufacturing sectors. These industries choose pure PTFE because its extreme chemical inertness and non-stick surface ensure that nothing leaches into or contaminates the process media, guaranteeing the integrity of the final product.

The decision to use pure PTFE in valve components is driven by one core requirement: preventing contamination. Its value lies not just in what it resists, but in what it doesn't do—it does not react, shed particles, or bind to the materials it contacts.

The Core Principle: Why Purity Demands Pure PTFE

To understand why these specific industries depend on pure PTFE, we must look beyond its general benefits and focus on the properties that directly support high-purity applications.

Unmatched Chemical Inertness

Pure PTFE is one of the most chemically resistant materials known. It is virtually immune to degradation from aggressive chemicals, solvents, and cleaning agents used in sterile environments.

This inertness means the valve component itself—be it a seat, gasket, or diaphragm—will not break down and release contaminants into a sensitive drug formulation or an ultra-pure water system.

The Anti-Contamination Surface

PTFE has an extremely low coefficient of friction, giving it a famously "non-stick" surface. In fluid handling, this prevents process media from adhering to the valve's internal surfaces.

This property is critical for preventing cross-contamination between batches and ensuring that systems can be cleaned completely and efficiently, a requirement in both food and pharmaceutical production.

Meeting Strict Regulatory Standards

The combination of inertness and purity allows pure PTFE to meet the stringent standards required in regulated industries. Materials used in these applications must often comply with guidelines from the FDA for food contact or achieve USP Class VI classification for medical and pharmaceutical use.

Key Industry Applications in Detail

While many industries use PTFE, its pure or virgin form is indispensable in these three high-stakes environments.

Pharmaceutical & Biotechnology

In drug manufacturing, even microscopic contamination can compromise the safety and efficacy of an entire batch. Pure PTFE is used for valve seats, diaphragms, and seals that come into direct contact with active pharmaceutical ingredients (APIs) and sterile solutions.

Its ability to withstand aggressive clean-in-place (CIP) and sterilize-in-place (SIP) procedures without degrading is essential for maintaining sterile processing environments.

Food & Beverage

Sanitary processing is paramount in the food and beverage industry to ensure consumer safety and product quality. Pure PTFE components prevent the transfer of flavors or odors between different products run on the same line.

The material’s resistance to caustic cleaning solutions and high temperatures makes it a durable choice for valves in dairy, brewing, and other food-grade liquid transfer systems.

Semiconductor Manufacturing

The fabrication of microchips requires the use of ultra-pure water (UPW) and highly aggressive chemicals. The slightest ionic or particulate contamination can cause defects, rendering millions of dollars worth of silicon wafers useless.

Pure PTFE is the standard for valves, tubing, and fittings in these fluid handling systems because it guarantees that no impurities are introduced into the manufacturing process.

Understanding the Trade-offs of Pure PTFE

While its purity is unmatched, pure PTFE is not the solution for every application. Understanding its limitations is key to using it effectively.

The Challenge of "Cold Flow"

Pure PTFE is a relatively soft material and has a tendency to deform under sustained pressure and temperature, a phenomenon known as creep or cold flow. Over time, this can compromise a valve's sealing capability in high-pressure applications.

Limited Mechanical Strength

Compared to other engineered polymers or metals, pure PTFE has lower tensile strength and abrasion resistance. It is not suitable for applications involving abrasive slurries or where high mechanical stress is a primary concern.

The Role of Filled or Reinforced PTFE

To overcome these mechanical limitations, fillers like glass fiber, carbon, or stainless steel are added to create Reinforced PTFE (RPTFE). These fillers dramatically improve strength and resistance to cold flow.

However, this comes at a price: the additives compromise the absolute purity of the material, making RPTFE unsuitable for the most sensitive pharmaceutical or semiconductor applications where virgin PTFE is required.

Making the Right Choice for Your Application

Selecting the correct material for your valve components requires balancing the need for purity against mechanical demands.

- If your primary focus is absolute product purity and avoiding contamination: Pure (virgin) PTFE is the only suitable choice for wetted valve components.

- If your primary focus is handling high pressure or abrasive media: Consider a reinforced PTFE (RPTFE) or another engineered polymer, as pure PTFE may deform or wear too quickly.

- If your primary focus is general chemical resistance in a less sensitive process: Pure PTFE is an excellent choice, but filled grades may offer better longevity and performance where absolute purity is not the top priority.

Ultimately, understanding the unique properties of pure PTFE allows you to protect the integrity and safety of your most critical processes.

Summary Table:

| Industry | Key Benefit of Pure PTFE | Common Valve Components |

|---|---|---|

| Pharmaceutical & Biotechnology | Prevents contamination of APIs; withstands CIP/SIP | Seats, Diaphragms, Seals |

| Food & Beverage | Prevents flavor transfer; resists cleaning agents | Seats, Gaskets, Liners |

| Semiconductor Manufacturing | Protects ultra-pure water & chemicals from impurities | Liners, Seals, Diaphragms |

Protect your product integrity with precision-engineered PTFE components from KINTEK.

Whether you require custom PTFE seals, liners, or labware for semiconductor, medical, or laboratory applications, KINTEK prioritizes precision production from prototypes to high-volume orders. Our expertise ensures your components meet the strictest purity and performance standards.

Contact KINTEK today to discuss your specific requirements and ensure contamination-free operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- What are the advantages of PTFE with a Proven Inorganic Filler? Maximize Metal Component Lifespan

- Why are PTFE valves used in chemical flow applications? For Unmatched Chemical Inertness and Purity

- What makes PTFE gaskets resistant to chemical corrosion? The Molecular Fortress Explained

- What are the different types of PTFE gaskets available? Choose the Right Seal for Your Application

- Why is cryogenic deburring particularly suitable for Teflon parts? Achieve a Perfect, Damage-Free Finish

- How does the application of PTFE gaskets improve equipment performance? Enhance Sealing Integrity & Reliability

- What is the wall thickness range for PTFE encapsulated O-rings? Optimize Seal Performance and Chemical Resistance