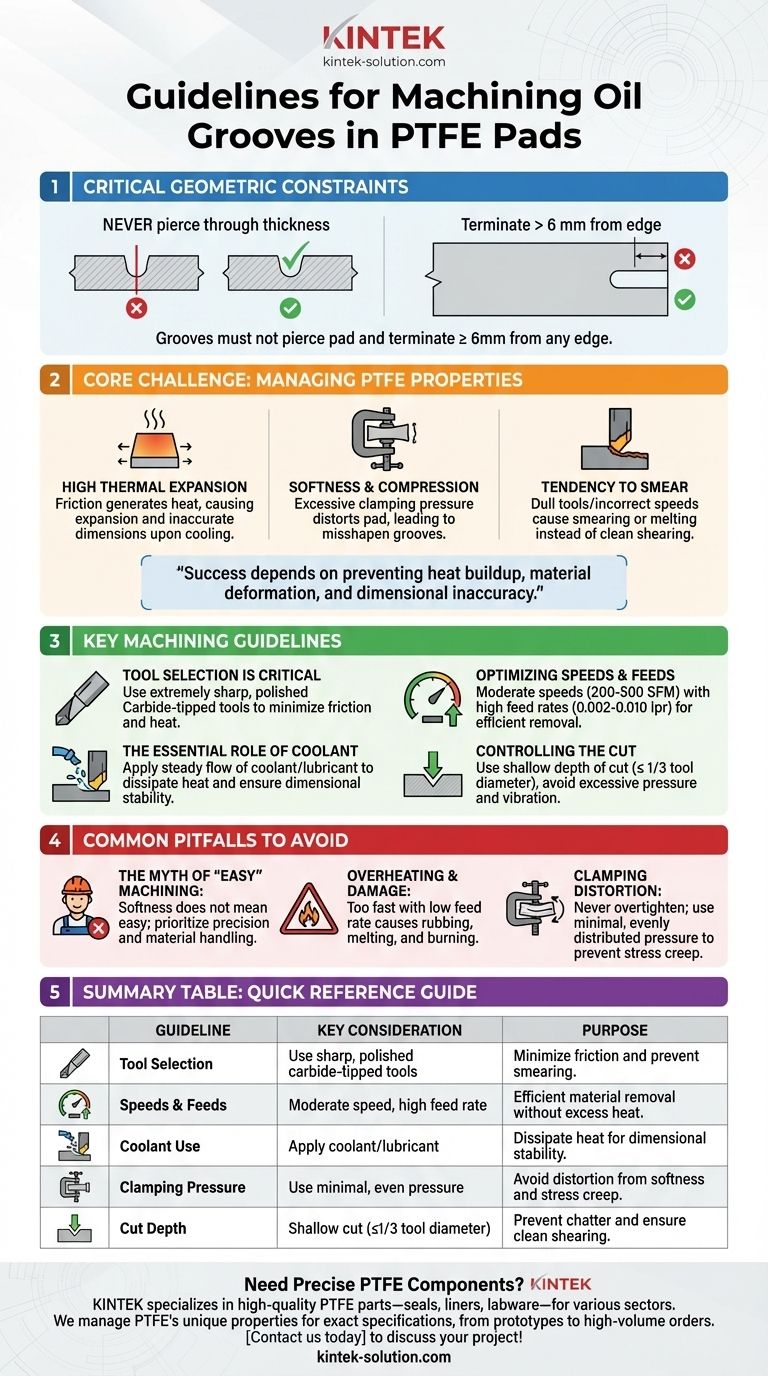

Machining oil grooves in PTFE pads is governed by a few critical geometric constraints and a deep understanding of the material's unique properties. The process is similar to machining cast iron, but the grooves must never pierce through the pad's thickness and must terminate at least 6 mm from any edge. While the specific shape and depth of the groove are flexible and depend on your application, successfully machining it requires specific techniques to manage PTFE’s nature.

The primary challenge isn't the geometry of the oil groove, but rather controlling PTFE's inherent softness and high thermal expansion during the machining process. Success depends on using the right tools and techniques to prevent heat buildup, material deformation, and dimensional inaccuracy.

The Core Challenge: Working with PTFE's Properties

To machine PTFE effectively, you must design your process around its fundamental characteristics, not in spite of them. Its softness makes it easy to cut, but its other traits present significant challenges to precision.

High Thermal Expansion

PTFE expands and contracts significantly with temperature changes. The friction from a cutting tool generates heat, which can cause the material to expand during the cut, leading to an inaccurate groove dimension once it cools.

Softness and Compression

The material is soft and can be easily compressed. Excessive clamping pressure will distort the pad, and any groove machined into it will be misshapen once the pressure is released. This property, known as stress creep, makes holding tight tolerances difficult.

Tendency to Smear

If cutting tools are dull or cutting speeds are incorrect, the PTFE can smear or melt rather than shear cleanly. This results in a poor surface finish and can clog the cutting tool.

Key Machining Guidelines for PTFE Grooves

Adhering to best practices for tooling, speeds, and workpiece handling is essential for a precise and clean result. These guidelines are designed to mitigate the challenges posed by the material itself.

Tool Selection is Critical

Your cutting tools must be extremely sharp and polished. Carbide-tipped tools are strongly preferred as they hold a sharp edge longer and generate less frictional heat than High-Speed Steel (HSS). A smooth tool surface ensures chips flow away easily.

Optimizing Speeds and Feeds

The goal is to remove material efficiently without generating excess heat. Use moderate cutting speeds (a starting point is 200 to 500 surface feet per minute) combined with relatively high feed rates (0.002 to 0.010 inches per revolution). A higher feed rate ensures the tool is constantly cutting fresh material and helps evacuate chips quickly.

The Essential Role of Coolant

Using a coolant or lubricant is highly recommended for any heat-intensive operations on PTFE. A steady flow of coolant dissipates heat at the cutting interface, preventing thermal expansion and ensuring dimensional stability.

Controlling the Cut

Use a shallow depth of cut, ideally no more than one-third of the tool's diameter. Avoid excessive pressure and vibration, as these can cause the soft material to chatter or deform, resulting in a poor surface finish.

Common Pitfalls to Avoid

Understanding what can go wrong is as important as knowing the correct procedure. Many machinists new to PTFE make predictable errors that compromise the final part.

The Myth of "Easy" Machining

While PTFE is soft and does not cause significant tool wear, this does not make it easy to machine precisely. Its softness is the source of the primary challenges: distortion under pressure and difficulty in achieving a clean shear.

Overheating and Material Damage

Running the tool too fast with a low feed rate is a common mistake. This causes the tool to rub against the material rather than cut it, generating intense localized heat that can melt or burn the PTFE, ruining the pad.

Clamping Distortion

Never overtighten a PTFE pad in a vise or fixture. The material will compress, and the machined groove will not meet its required dimensions after the part is released. Use minimal, evenly distributed clamping pressure.

Making the Right Choice for Your Goal

Your specific objective will determine which aspect of the process you need to prioritize.

- If your primary focus is dimensional accuracy: Prioritize thermal management with ample coolant and use minimal clamping pressure to prevent any distortion of the pad.

- If your primary focus is a clean surface finish: Use exceptionally sharp, polished carbide tools with high feed rates to ensure the material shears cleanly instead of smearing.

- If you are setting up a new process: Begin with conservative cutting speeds and focus on effective chip removal before gradually increasing parameters to find the optimal balance for your equipment.

Ultimately, successful PTFE machining comes from respecting the material's unique properties through careful preparation and precise execution.

Summary Table:

| Guideline | Key Consideration | Purpose |

|---|---|---|

| Tool Selection | Use sharp, polished carbide-tipped tools | Minimize friction and prevent material smearing |

| Speeds & Feeds | Moderate speed (200-500 SFM), high feed rate | Efficient material removal without excess heat |

| Coolant Use | Apply coolant/lubricant during cutting | Dissipate heat to maintain dimensional stability |

| Clamping Pressure | Use minimal, even pressure | Avoid distortion from PTFE's softness and stress creep |

| Cut Depth | Shallow cut (≤1/3 tool diameter) | Prevent chatter and ensure clean shearing |

Need precise, custom-machined PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing PTFE's unique properties ensures your components are machined to exact specifications, avoiding common pitfalls like thermal expansion and deformation.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability. Let us handle the complexities of PTFE machining for you.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is expanded PTFE used in fluorofiber applications? Leverage Unmatched Strength & Chemical Resistance

- What are the main features of PTFE bellow mechanical seals? A Guide to Extreme Chemical Resistance and Reliability

- What are PTFE Bellows and what material are they made from? Discover the Key to Chemical Resistance & Flexibility

- How do PTFE gaskets benefit the mechanical equipment industry? Enhance Equipment Reliability and Longevity

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What are the advantages of Teflon bushes' low friction? Achieve Maintenance-Free, Long-Lasting Performance

- What makes PTFE washers ideal for high and low temperature applications? Ensuring Reliable Performance in Extreme Environments

- What are the operational temperature limits for PTFE-lined diaphragm valves? Understanding the Full System Range