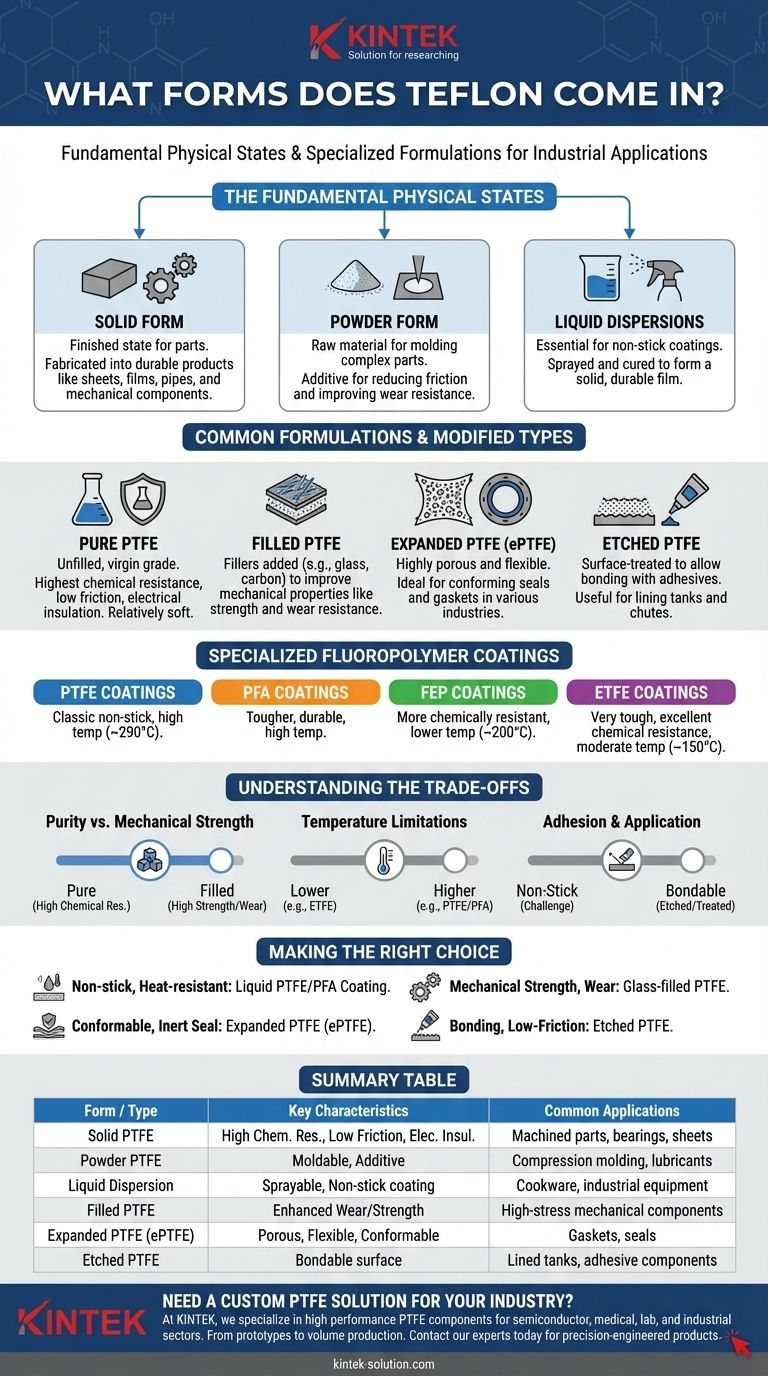

In its simplest terms, Teflon exists in three primary physical states. It is available as a solid, a fine powder, or a liquid dispersion. These fundamental forms are then processed and engineered into a vast array of specialized products, each tailored for specific industrial, mechanical, or chemical applications.

The critical insight is that "form" goes beyond the physical state of solid, liquid, or powder. The true determinant for any application is the specific formulation (e.g., pure, filled, or expanded) and the final fabricated product (e.g., a coating, a seal, or a bearing).

The Fundamental Physical States

Polytetrafluoroethylene (PTFE), the chemical name for Teflon, begins in one of three states before being manufactured into a final product.

Solid Form

This is the most common perception of Teflon. It is the finished state for many mechanical parts and stock shapes.

These solid forms are fabricated into specific, durable products like sheets, films, pipes, and mechanical components.

Powder Form

Fine PTFE powders serve as the raw material for molding complex parts. This form allows manufacturers to create custom shapes through compression and sintering.

Powders can also be used as an additive in other materials to reduce friction or improve wear resistance.

Liquid Dispersions

Liquid Teflon consists of microscopic PTFE particles suspended in a liquid carrier. This is the essential form for creating non-stick coatings.

This liquid is sprayed or applied to a substrate, such as cookware or industrial equipment, and then baked to form a solid, durable film.

Common Formulations and Modified Types

The base PTFE polymer is often modified with other materials to enhance specific properties. Understanding these formulations is key to selecting the right material.

Pure PTFE

This is the unfilled, virgin grade of Teflon. It offers the highest chemical resistance, the lowest coefficient of friction, and excellent electrical insulation.

Its primary trade-off is its relative softness and lower resistance to wear and creep compared to filled grades.

Filled PTFE

Fillers are added to the PTFE powder before processing to improve mechanical properties. A common example is glass-filled PTFE, which significantly increases strength and wear resistance.

Other fillers, like carbon or graphite, can be used to enhance lubrication or thermal conductivity.

Expanded PTFE (ePTFE)

ePTFE is a highly porous and flexible material created by rapidly stretching pure PTFE. This structure makes it ideal for sealing applications.

Its softness and flexibility allow it to conform to irregular surfaces, creating highly effective gaskets and seals, especially in food and pharmaceutical uses.

Etched PTFE

One of Teflon's defining features is that it's non-stick, which makes it very difficult to bond to other surfaces.

Etched Teflon is surface-treated on one side to allow it to be bonded with adhesives, making it useful for lining tanks or chutes.

Specialized Fluoropolymer Coatings

While "Teflon" is often used synonymously with the PTFE non-stick pan coating, it represents a family of related fluoropolymer coatings.

PTFE Coatings

This is the classic coating known for its exceptional non-stick properties and high-temperature resistance, typically up to 290°C.

PFA Coatings

PFA (Perfluoroalkoxy) coatings are tougher and more durable than PTFE, offering similar high-temperature resistance and chemical inertness.

FEP Coatings

FEP (Fluorinated Ethylene Propylene) is more chemically resistant than PTFE but has a lower maximum operating temperature, around 200°C.

ETFE (Tefzel) Coatings

ETFE is a very tough and durable coating that offers excellent chemical resistance with a continuous service temperature of 150°C.

Understanding the Trade-offs

Choosing the right form of Teflon requires balancing its inherent properties with the demands of the application.

Purity vs. Mechanical Strength

Pure, virgin PTFE offers the best chemical and electrical properties but is mechanically soft. Adding fillers like glass or carbon dramatically improves wear resistance and compressive strength but may slightly alter its chemical resistance or coefficient of friction.

Temperature Limitations

While known for high-temperature performance, each fluoropolymer type has a distinct limit. PTFE and PFA are suitable for the highest temperatures, while FEP and ETFE are used for more moderate conditions. Exceeding these limits can cause the coating or material to degrade.

Adhesion and Application

The innate non-stick quality of Teflon is a significant challenge when bonding is required. Unless you are using a specially treated product like Etched Teflon, standard adhesives will fail. Similarly, coatings require a liquid dispersion and specialized application and curing process.

Making the Right Choice for Your Application

Your final selection depends entirely on the primary performance goal you need to achieve.

- If your primary focus is a non-stick, heat-resistant surface: A liquid-based PTFE or PFA coating is the correct choice.

- If your primary focus is mechanical strength and wear resistance: A solid component made from a glass-filled PTFE formulation is likely required.

- If your primary focus is creating a conformable, chemically inert seal: The porous structure of expanded PTFE (ePTFE) is engineered for this purpose.

- If your primary focus is bonding a low-friction surface to another material: You must use a surface-treated solid form like Etched Teflon.

Ultimately, understanding these variations allows you to select a Teflon product precisely engineered to meet your specific performance demands.

Summary Table:

| Form / Type | Key Characteristics | Common Applications |

|---|---|---|

| Solid PTFE | High chemical resistance, low friction, electrical insulation | Sheets, rods, tubes, machined parts, bearings |

| Powder PTFE | Moldable, used as an additive for friction reduction | Compression molding, additive for lubricants |

| Liquid Dispersion | Sprayable, forms non-stick coatings after curing | Non-stick cookware, industrial equipment coatings |

| Filled PTFE | Enhanced wear resistance, strength (e.g., glass-filled) | High-stress mechanical components, seals |

| Expanded PTFE (ePTFE) | Porous, flexible, conformable | Gaskets, seals in food, pharmaceutical industries |

| Etched PTFE | Bondable surface via treatment | Lined tanks, adhesive-bonded components |

Need a Custom PTFE Solution for Your Industry?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, we deliver precision-engineered Teflon products tailored to your exact requirements.

Let us help you select the right form of PTFE for your application. Contact our experts today to discuss your project and receive a customized solution that meets your performance and durability needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE benefit the semiconductor industry? Essential for High-Purity Chip Fabrication

- What is PTFE and how does its chemical structure compare to polyethylene? Unlocking Superior Material Performance

- How is PTFE used in pharmaceutical and medical applications? Essential for Safety & Efficiency

- What are the environmental impacts of PTFE production? The Truth About PFAS & 'Forever Chemicals'

- What is PTFE and its basic chemical structure? The Key to Its Legendary Performance

- Why are PTFE products widely used across various industries? Discover the 4 Key Properties

- How does PTFE perform when exposed to different types of water? Unmatched Chemical Resistance in Any Aqueous Environment

- Is PTFE coating safe to use? A Guide to Safe Temperatures and Applications