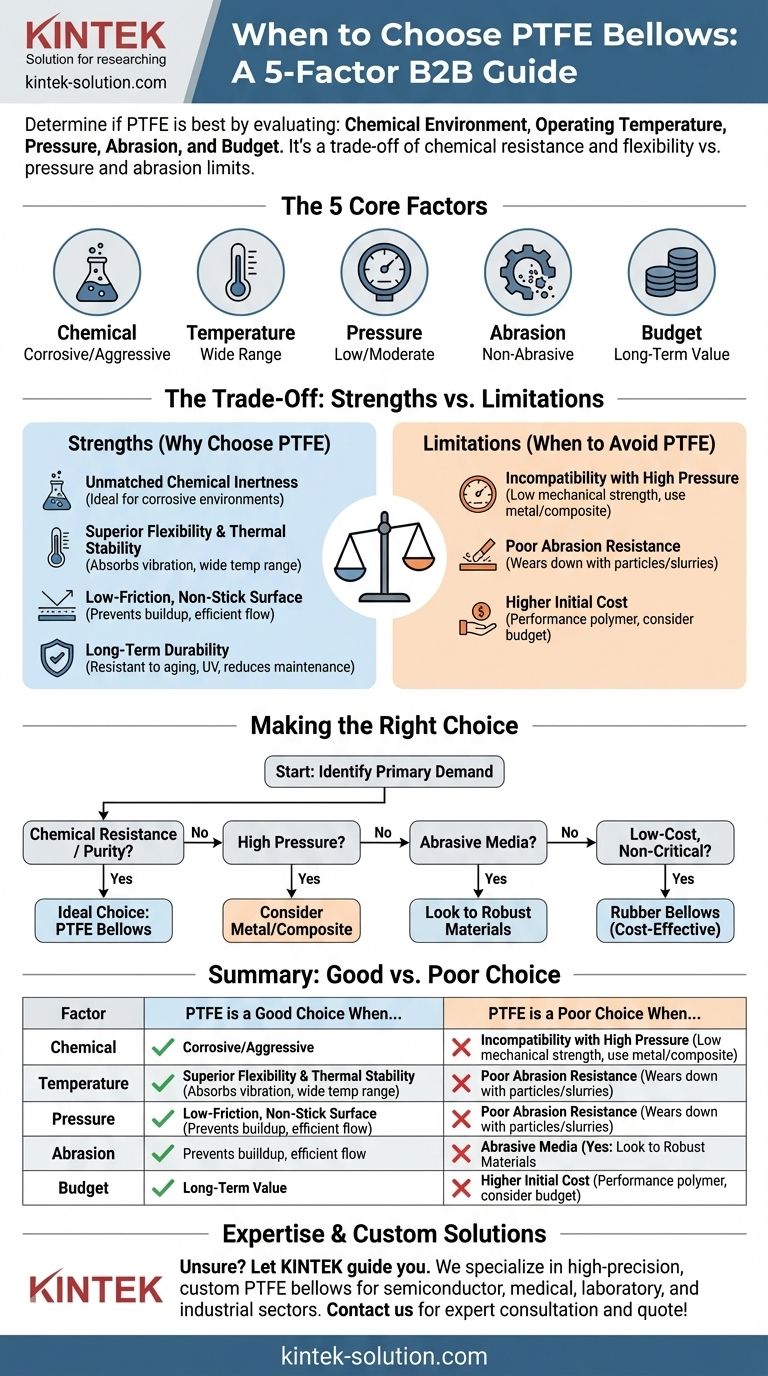

To determine if PTFE bellows are the best choice, you must evaluate five core factors for your specific system: the chemical environment, operating temperature range, pressure levels, the presence of abrasive media, and budget constraints. PTFE excels in chemically aggressive environments but is generally unsuitable for high-pressure or abrasive applications.

The decision to use PTFE bellows hinges on a clear trade-off. You are selecting a material with unparalleled chemical resistance and flexibility, but you must accept its inherent limitations in handling high pressure and abrasive particles.

The Core Strengths of PTFE Bellows

Understanding where PTFE excels is the first step in making an informed decision. Its unique properties make it a first-choice material for a specific range of demanding applications.

Unmatched Chemical Inertness

PTFE is famously non-reactive. This makes it an ideal material for bellows in corrosive and chemically aggressive environments where other materials would quickly degrade.

This is why PTFE is a standard in industries like chemical and pharmaceutical processing, petrochemical pipelines, and semiconductor manufacturing.

Superior Flexibility and Thermal Stability

PTFE bellows exhibit excellent flexibility and a long flex life, allowing them to effectively absorb vibration, shock, and thermal expansion within a system.

They also operate reliably across a wide temperature range, handling extremes that would compromise many other polymers.

Low-Friction, Non-Stick Surface

The material's non-stick and repellant properties are a significant advantage. This low-friction surface prevents deposit buildup from the media flowing through the system.

This ensures more efficient fluid flow, reduces the risk of blockages, and is critical for high-purity applications where contamination is a concern.

Long-Term Durability and Reliability

PTFE is highly resistant to degradation from aging or exposure to sunlight (UV radiation). This contributes to a long service life, which can reduce long-term maintenance costs and system downtime.

Understanding the Trade-offs: Key Limitations

No material is perfect for every situation. Being aware of PTFE's weaknesses is just as important as knowing its strengths to prevent system failure.

Incompatibility with High Pressure

The primary limitation of PTFE is its low mechanical strength. It is not designed to handle high-pressure applications.

For high-pressure systems, metal or robust composite bellows are almost always a more appropriate and safer choice.

Poor Abrasion Resistance

PTFE is a relatively soft material. If your system's media contains abrasive particles or slurries, PTFE bellows will wear down and fail prematurely.

In these scenarios, a hard-wearing metal or specialized composite bellow is the necessary alternative.

The Cost Factor

PTFE is a high-performance polymer, and its cost often reflects that. It can be more expensive than other options like rubber or certain composites.

While its long lifespan can offset the initial investment in the right context, budget constraints must be a key part of the evaluation.

Making the Right Choice for Your Application

Use your system's primary demand as the guiding factor in your material selection.

- If your primary focus is chemical resistance or purity: PTFE is likely the ideal choice due to its inertness and non-stick properties.

- If your primary focus is managing high system pressure: You should strongly consider metal or composite bellows instead of PTFE.

- If your system contains abrasive media: PTFE's low abrasion resistance makes it unsuitable; look to more robust materials.

- If your primary focus is a low-cost solution for a non-critical application: A rubber bellow may be more cost-effective, provided the chemical and temperature demands are low.

By balancing these distinct strengths and limitations against your application's needs, you can confidently select the material that ensures the long-term integrity and efficiency of your system.

Summary Table:

| Factor | PTFE Bellows are a Good Choice When... | PTFE Bellows are a Poor Choice When... |

|---|---|---|

| Chemical Environment | Handling highly corrosive or aggressive chemicals. | The environment is chemically mild. |

| Temperature | Operating across a wide temperature range. | Extreme temperatures exceed PTFE's limits. |

| Pressure | System pressure is low to moderate. | System pressure is high. |

| Abrasion | The media is non-abrasive. | The media contains abrasive particles or slurries. |

| Budget | Long-term chemical resistance and purity justify the investment. | A low-cost solution for a non-critical application is needed. |

Still Unsure if PTFE Bellows Are Right for Your Application?

Let KINTEK's expertise guide you. We specialize in manufacturing high-precision PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our team can help you analyze your specific requirements for chemical resistance, temperature, pressure, and purity to determine the optimal material solution.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a reliable component that maximizes your system's performance and longevity.

Contact KINTEK today for a expert consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining