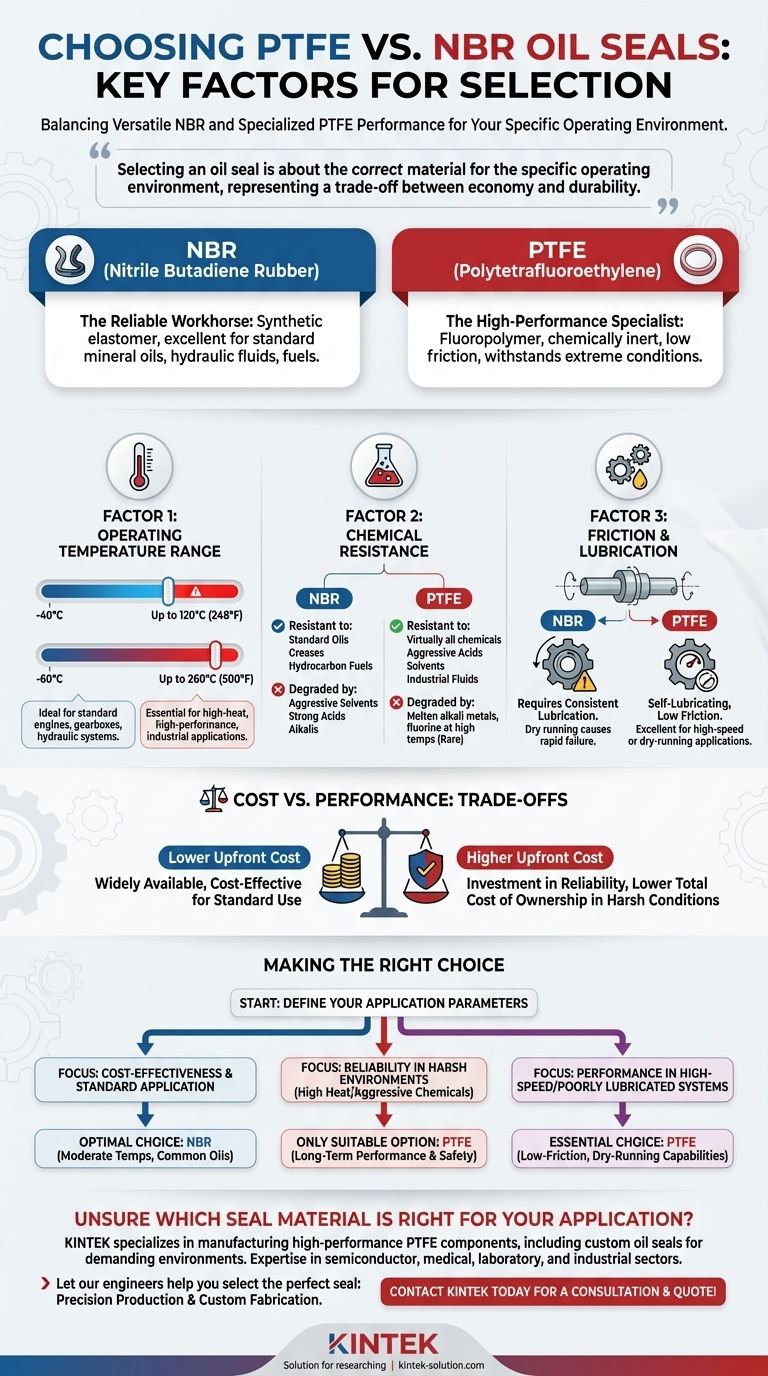

The primary factors for choosing between PTFE and NBR oil seals are operating temperature, chemical exposure, lubrication conditions, and budget. NBR (Nitrile Butadiene Rubber) is the industry standard for general-purpose applications with moderate temperatures and standard oils, offering a cost-effective solution. PTFE (Polytetrafluoroethylene) is a high-performance material required for extreme heat, aggressive chemicals, or applications with poor lubrication where NBR would quickly fail.

Selecting an oil seal is not about choosing the "best" material, but the correct material for the specific operating environment. The choice represents a critical trade-off between the versatile, economical performance of NBR and the specialized, durable performance of PTFE required for harsh conditions.

The Fundamental Difference: Material Properties

Understanding the core nature of each material is the first step in making an informed decision. They are engineered for fundamentally different challenges.

NBR (Nitrile Butadiene Rubber): The Reliable Workhorse

NBR is a synthetic elastomer, a type of rubber valued for its flexibility and resilience. It creates a reliable seal by being compressed into place, conforming to surface imperfections.

Its primary strength is its excellent resistance to common petroleum-based oils, hydraulic fluids, and fuels, making it the default choice for a vast range of standard mechanical applications.

PTFE (Polytetrafluoroethylene): The High-Performance Specialist

Often called the 'king of plastics,' PTFE is a fluoropolymer with unique characteristics. Its strong carbon-fluorine bonds make it one of the most chemically inert substances known.

This structure also gives PTFE an extremely low coefficient of friction and a non-stick surface, allowing it to handle demanding situations that would destroy a standard rubber seal.

A Head-to-Head Comparison of Key Factors

Your operating conditions will point directly to the correct material. Answering the following questions is the most reliable way to determine your needs.

Factor 1: Operating Temperature Range

This is often the first and most decisive factor. An elastomer like NBR has a clear thermal limit beyond which it will harden, crack, and fail.

NBR seals are generally rated for continuous operation up to 120°C (248°F). They are ideal for standard engine, gearbox, and hydraulic systems.

PTFE seals excel in high-heat environments, withstanding continuous temperatures up to 260°C (500°F). This makes them essential for high-performance or industrial applications where heat is a major concern.

Factor 2: Chemical Resistance

The fluid being sealed is the next critical consideration. Mismatched chemical compatibility is a primary cause of seal degradation and leakage.

NBR provides excellent resistance to standard mineral oils, greases, and many hydrocarbon fuels. However, it can be degraded by aggressive solvents, strong acids, or alkalis.

PTFE is virtually immune to all chemicals, including aggressive acids, solvents, and industrial fluids. If the medium is anything other than a standard lubricant or fuel, PTFE is the safer choice.

Factor 3: Friction and Lubrication

The dynamics of the rotating shaft play a major role in seal life and performance. Friction generates heat and wear, which must be managed.

NBR seals require consistent lubrication from the sealed fluid to minimize friction and prevent overheating. Running an NBR seal dry, even for a short time, can cause rapid failure.

PTFE seals have an exceptionally low coefficient of friction and are self-lubricating. This allows them to be used in high-speed applications or in conditions where lubrication might be intermittent or minimal (dry running).

Understanding the Trade-offs: Cost vs. Performance

While technical requirements should always come first, budget is a practical reality that cannot be ignored.

The Cost Equation

NBR is a mature, high-volume material, making it significantly more affordable and widely available. For applications where its performance is sufficient, it is the clear economic choice.

PTFE is a more specialized material that is more complex to manufacture into seals. This results in a significantly higher upfront cost per unit.

Long-Term Value and Reliability

Choosing a seal based on upfront cost alone can be a costly mistake. Placing an NBR seal in a high-temperature or chemically aggressive environment will lead to premature failure.

The resulting equipment downtime, labor for replacement, and potential damage from leakage will far exceed the initial savings. In harsh conditions, the higher cost of a PTFE seal is an investment in reliability and a lower total cost of ownership.

Making the Right Choice for Your Application

Use your specific operational parameters to guide your final decision. The answer becomes clear when you define the problem correctly.

- If your primary focus is cost-effectiveness for a standard application: NBR is the optimal choice for moderate temperatures (<120°C) and sealing common oils and fuels.

- If your primary focus is reliability in high-heat or chemically aggressive environments: PTFE is the only suitable option to ensure long-term performance and safety.

- If your primary focus is performance in high-speed or poorly lubricated systems: PTFE's low-friction and dry-running capabilities are essential to prevent premature wear and failure.

Ultimately, matching the material's properties to the application's demands is the foundation of reliable engineering.

Summary Table:

| Factor | NBR (Nitrile Butadiene Rubber) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Operating Temperature | Up to 120°C (248°F) | Up to 260°C (500°F) |

| Chemical Resistance | Excellent for standard oils, fuels; poor for aggressive chemicals | Excellent; virtually inert to all chemicals, acids, solvents |

| Lubrication | Requires consistent lubrication; dry running causes failure | Self-lubricating; excellent for high-speed or dry-running applications |

| Cost | Cost-effective; ideal for standard applications | Higher upfront cost; justified for harsh conditions and reliability |

Unsure which seal material is right for your application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom oil seals, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal that delivers maximum reliability and a lower total cost of ownership.

Let our engineers help you select the perfect seal:

- Precision Production: We prioritize exacting standards for consistent performance.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your needs.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications